| Q. | Which product is NOT dried by spray dryer? |

|---|---|

| B. | Fruit Juice |

| C. | Lactose |

| D. | Bacterial & viral cultures |

| Answer» d. Bacterial & viral cultures |

What is the principle of spray dryer? A spray dryer takes a liquid stream and separates the solute or suspension as a solid and the solvent into a vapor. The solid is usually collected in a drum or cyclone. The liquid input stream is sprayed through a nozzle into a hot vapor stream and vaporized. Solids form as moisture quickly leaves the droplets.

What are the advantages of spray dryer? Benefits of Spray-Drying Some of the advantages of spray-drying include its ability to be fully automated and continuous. Short residence times and suitability for both heat-sensitive and heat-resistant foods are other advantages. The technology is suitable for a variety of feed materials, provided they are pumpable.

What temperature is spray drying? The typical spray drying process used today employs air heated up to 400° Fahrenheit to dry an atomized liquid into a powder.

How many types of spray dryers are there? … Among them are the rotary, nozzle, two-fluid, pressure and ultrasonic nozzle (Walzel, 2011). Atomization is a crucial part of the spray dryer because it influences the drying rate, particle diameter, particle distribution, and dispersibility of the powder for rehydration (Chegini & Taheri, 2013) .

What is atomizer in spray dryer? In spray dryers, atomizer system is much like a knife that needs to cut fluid particles precisely into finar parts, and if the automizer fails, it can have serious consequences. Atomization system works to chop up the liquid droplets into even finer droplets in order to serve the higher surface area to volume ratio.

Which product is not tried by spray dryer? – Related Questions

How long does spray drying take?

3.2 Spray Drying Drying is accomplished within a few seconds. The dried product is removed from the bottom of the tower, and the waste gas stream exhausted through a cyclonic dust separator.

How efficient is spray drying?

The hot air is used as the drying medium in spray dryer. It was reported that the heat efficiency of spray dryer is about 25% to 60%, and some even are below 20%[1].

What is the difference between a dryer and a spray dryer?

Spray dryers can dry very quickly compared to other methods. They also turn a liquid into a dried powder in a single step, which simplifies and improves profit margins. The development of spray drying equipment and techniques evolved from the 1870s through the early 1900s.

Who invented spray dryer?

Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [1, 2, 3]. Ever since it was first discovered, the spray-drying technique has been improved concerning its operational design and applications.

How can I increase the efficiency of my spray dryer?

Spray drying energy efficiency can be improved by widening the gap between inlet and outlet temperatures and adding heat recovery equipment. For many years, spray drying has been one of the most energy-consuming drying processes, yet it remains one that is essential to the production of dairy and food product powders.

How can I increase the capacity of my spray dryer?

Evaporation is defined as the difference between inlet and outlet temperature, or ΔT, in the drying air. The larger the ΔT, the greater the capacity of the spray dryer. The goal in optimizing a spray dryer’s capacity is to increase ΔT by raising the inlet temperature or lowering the outlet temperature.

How do you use a spray dryer?

What is the main difference in using single two and three stage spray dryer?

Two Stage Spray Dryer – spray dryers followed by fluid bed dryer for drying products which require longer residence time & product conditioning post drying. Three Stage Spray Dryer – spray dryers with Internal fluid bed followed by external fluid bed dryer for producing dust free agglomerates.

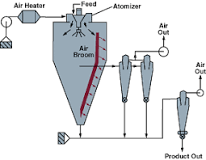

What are the components of spray dryer?

- feed pump.

- atomizer or spray nozzles.

- air heater, air disperser.

- drying chamber.

- powder recovery systems.

- process control systems.

- Click here to learn the specifications of PacMoore’s spray dryers.

Which of the following is type of atomizer used in spray dryer?

Essentially, three major types of atomizers are used in practice. They are: (a) Rotary wheel (or disk) atomizers, (b) Pressure nozzle and (c) Two-fluid nozzle.

What is atomization spray?

Spray atomization is the transformation of a liquid into a spray of fine particles in a vacuum or a surrounding gas. The breakdown of the liquid into small particles is achieved when compressed air mixes with the liquid.

What is the difference between spray drying and freeze-drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

What is the size range of particle produced from spray drying?

The droplets lose moisture rapidly and dry when they meet a stream of hot gas. The drying occurs in an insulated chamber. Powders produced have relatively uniform characteristics and are collected from the spray dryer. Spray drying usually provides particles with a mean particle size below 10 μm, preferably 5 μm.

What is cyclone in spray dryer?

Cyclone separators are used in the dairy industry for • gas–solids separation, mainly for separating product fines from the air leaving spray dryers and fluidized bed dryers, both to increase yield and to minimize air pollution. This is the commonest application of cyclones.

What is spray dryer PDF?

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.

What are the spray dryer parts and function?

A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. The three stages that occur in a spray dryer before drying is accomplished include: Atomization. Spray-air mixing and moisture evaporation.

What is spray drying in pharmaceutical industry?

Spray drying is a drying technique used in the pharmaceutical industry to produce dry or coarse powder from liquid or slurry. It is usually used in the production of active pharmaceutical ingredients (APIs), the active ingredients in drugs.

What is spray drying in food preservation?

Spray drying is the process where a mixture of compounds is made in its liquid or slurry form that is finally converted into dry powder form. This drying technique emerged way back in 1860s and was used during World War II. It helped to make easy shipment of larger quantities of food within limited storage area.

What is spray dryer PDF?

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.