What is a downdraft spray booth? In a downdraft booth, the air creates an envelope around the car. The air is drawn down, and over the vehicle, excess overspray is carried into the pits, through a series of filters before being exhausted to the atmosphere. Full downdraft paint booths require a pit for the airflow path.

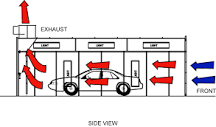

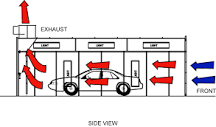

How does a semi-downdraft spray booth work? The semi-downdraft design achieves the benefits of a downdraft booth by pressurizing the air through a supply plenum that is typically located near the front of the booth. The pressurized fresh air is released from the top of the booth, then flows diagonally across and down towards the rear of the booth enclosure.

What is a semi-downdraft? The semi-downdraft booth is a hybrid, combining features of both crossdraft and downdraft booths. Air is introduced into semi-downdraft paint booths through the ceiling in the first 25 to 30 percent of the booth.

Does a spray booth need ventilation? Airflow in paint spray booths Booths are usually configured in one of two ways to provide adequate ventilation. These are downdraft and cross draft. In a downdraft booth an exhaust fan installed low down pulls out vapor-laden air while make-up air enters from the top of the booth.

How many CFM do I need for spray booth? Multiply the booth’s face area by 100 feet per minute to achieve CFM. One hundred feet per minute is the guideline for air movement in the booth area. Using the example from above, 80 square feet multiplied by 100 feet per minute equals 8,000 CFM. This is the size of the fan needed.

How do you make a small spray paint booth? – Related Questions

Why do spray booths operate at negative pressure?

Spray painting booth ventilation relies on the balance of the exhaust fan and the air replacement fan. If just the exhaust fan is on, the booth takes on negative pressure, since more air is being removed than pushed in.

What are the different types of spray booth?

These configurations include crossflow, semi-downdraft, side-downdraft, and downdraft. A crossflow booth is one that is typically designed such that the air moving through the booth travels across the area from one end (or side) of the booth to the other.

How much ventilation does a paint booth need?

You need to ensure a minimum of four air exchanges per minute when solvent-based or wet paints are used in the booth. For powder-coating finishes, the minimum airflow required is 60 lfm.

Which type of spray booth is the most popular air movement system used today?

Without such a system in place you have what’s called “negative pressure booth” which pulls in shop air usually through filtered doors commonly known as a Cross Draft Paint Booth. This is the most popular and economical booth models available.

What are the 3 types of paint booths?

There are four main types of automotive paint booths to choose from including a crossdraft booth, semi downdraft, sidedraft and downdraft.

How do you make a homemade paint booth?

What makes a good paint booth?

Eco-friendliness – A good paint booth doesn’t only protect its operators, it’s also good for the environment. Productivity – Your paint booth should help you work faster and more efficiently. Look for a paint booth that can help you reduce production time and wastage.

Should a paint booth have negative pressure?

A slightly positive booth pressure prevents dust and dirt from being pulled into the paint booth, while a slightly negative pressure may be recommended so vapors cannot escape the spray booth and contaminate other work areas. The paint booth pressure is related to airflow.

Why are paint booths white?

White pre-coated walls are typically standard with dual-skin booths and may be an option on single-skin booths. White walls increase the reflectability of the lights, making it easy to see what you are painting.

How do you ventilate a paint booth?

FANS TO PUSH AND PULL The exhaust fan that PULLS the air out of the Standard Tool’s paint booths is a tube-axial exhaust fan. It is a propeller blade type fan. Tube-axial is the best fan to be used on the exhaust of the booth because they are designed to pull the air.

How often should spray booth filters be changed?

A good rule of thumb is that your exhaust filter will work best for the first 50-60 hours of spraying. You should expect to change your exhaust filters every 2 weeks during normal use. This will keep your exhaust fan working properly and ensure that clean air is released into your shop.

How many CFM do I need for my shop ventilation?

| Typical | Range | |

|---|---|---|

| Print Shops | 7 | 4-10 |

| Restaurants | 6 | 2-10 |

| Rest Rooms | 7 | 4-10 |

| Schools | 7 | 4-10 |

How do you ventilate a room for spray painting?

Ventilation is key You should only use spray paint in a well-ventilated area. Open any windows and turn on a fan if you have one. The fumes from spray paint, even if you’re using a low odor paint option, is not good to inhale for any period of time.

What temperature is best for spray painting?

Ideally, temperatures should be between 50°F and 90°F, and relative humidity is below 85%. Avoid painting in direct sunlight and hot, humid weather.

How do you measure air flow in a spray booth?

What is static pressure in paint booth?

Static Pressure is defined as pressure exerted by liquid or gas (water or air) when bodies on which the pressure is exerted are not in motion. 9 Airflow within a booth (or confined area) must overcome resistance from ductwork and filters when moving from one point to another.

Which of these types of airflow does a downdraft spray booth provide?

3. Downdraft Booths. Downdraft booths indisputably have the best airflow style for controlling overspray and contamination. Like side downdraft booths, uniform airflow is achieved through a full-length, filtered ceiling and exhaust pit that runs nearly the entire length of the booth.

What is a cross draft paint booth?

What Does a Crossdraft Paint Booth Do? Crossdraft paint booths provide a high-quality finish similar to downdraft paint booths, but instead of the airflow coming down, it goes directly across the object that’s being painted.

Who makes DeVilbiss paint booths?

In 1990, DeVilbiss was acquired by ITW, a tool manufacturer based in Chicago.

How does a cross flow spray booth work?

How does a cross draft paint booth work? The cross draft spray booth works by drawing air horizontally over the object to be painted. Typically, air is drawn directly from the shop environment through filters located within the doors of the spray booth.

Which booth air leaves through a metal grate?

Most common are pit style booths that utilize an excavated pit and tunnel system to draw air from the centre portion of the booth floor. Also quite common are raised floor or “basement” style booths that draw air through grating in the booth floor.

Which type of spray booth is the most popular air movement system used today?

Without such a system in place you have what’s called “negative pressure booth” which pulls in shop air usually through filtered doors commonly known as a Cross Draft Paint Booth. This is the most popular and economical booth models available.

How do you ventilate a paint booth?

FANS TO PUSH AND PULL The exhaust fan that PULLS the air out of the Standard Tool’s paint booths is a tube-axial exhaust fan. It is a propeller blade type fan. Tube-axial is the best fan to be used on the exhaust of the booth because they are designed to pull the air.

How does a cross flow spray booth work?

How does a cross draft paint booth work? The cross draft spray booth works by drawing air horizontally over the object to be painted. Typically, air is drawn directly from the shop environment through filters located within the doors of the spray booth.