Electroplating – A process of coating a metal with a thin layer of another metal by electrolysis to improve the metal’s corrosion resistance. Sherardizing – The formation of a corrosion-resistant, zinc-iron alloy coating on the surface of steel or iron.

What is metal spray coating? What Does Metal Spray Coating Mean? Thermal spraying is a group of coating processes in which finely divided metallic or nonmetallic materials are deposited in a molten or semi-molten state to form a coating. The coating material may be a powder, ceramic rod, wire or molten material.

What are the disadvantages of metal spraying? The main disadvantage of flame spraying is the level of coating quality. Powder flame sprayed coatings tend to have high porosity (10-20 vol%), low density and high oxide levels (10-20 wt%) for metal deposits, and lower bond strength than coatings prepared by other thermal spraying processes.

Which equipment is used in metal spraying process? Our Metal Spray equipment consists of Arc Spray, Flame Spray, Plasma Spray, High Velocity Air-Fuel (HVAF), High Velocity Oxygen-Fuel (HVOF), Laser Cladding, Spray Weld Equipment and also Ancillary Equipment.

What is metal spraying used for? Metal spraying is used to protect LPG, propane gas or butane gas bottles against corrosion. Gas cylinders are often refurbished and, as part of that process, the surface of the bottles is grit blasted to prepare it prior to spraying with zinc. LPG cylinders are usually metal sprayed using the arc spray process.

How many types of coating are there? Coatings are varied, but primarily fall into three categories: Architectural, Industrial, and Special Purpose.

What is metal coating called? – Related Questions

What is the method of metal coating?

There are four commonly used methods of applying metal coating to steel surfaces. These are hot-dip galvanizing, thermal spraying, electroplating and sherardizing. The latter two processes are not used for structural steelwork but are used for fittings, fasteners and other small items.

What are the two main methods of metal spraying?

Both flame spraying and arc spraying techniques are used to add these protective coatings.

How does thermal spray work?

The Basics of Thermal Spraying Combined thermal and kinetic energy causes the particles to flatten or ‘splat’ onto the surface, and onto each other, to produce a cohesive coating of successive layers. Metallurgically cold process.

What is spraying process?

The word ‘spraying’ generally refers to coating processes that use a spray of particles or droplets to deposit a material onto a substrate.

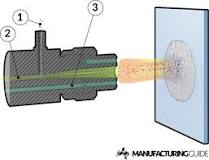

What is powder metal spraying process?

The process A powder [1] is fed into the spray gun and mixed with a fuel gas [2] under pressure. The gas burns with the help of the oxygen supply [3] and reaches a temperature of about 3000 degrees Celsius causing the powder to melts. The molten powder is sprayed on and coats the workpiece.

Which is a spray material?

With cermet spray materials, consisting of hard ceramic particles and metallic binder, effort is generally made to retain the hard phase in the powder to deposit so that the compositions and microstructure of the composite deposit can be designed through powder design. WC–Co is a typical material of this kind.

What materials can be thermal sprayed?

Thermal Spray is a range of high-performance ceramic, cermet and metallic coatings that can be applied to a range of steel, titanium, aluminium, and copper alloys, as well as to some non-metallic substrates.

How do you spray Weld?

What is arc spraying?

Arc spraying uses an electric arc as the heat source to melt metallic wires. Similarly to flame, compressed air (or sometimes inert gas) is used to atomise the molten metal. The electric arc is created by charging one wire positive, the other wire negative and forcing the two wires together to create the electric arc.

What is metallization process?

Metallization is a general term that refers to the application of a metal coating to another metallic or non-metallic surface. Depending on the desired result, the coating can consist of metals such as zinc, gold, aluminum or silver.

What paint is used for metal?

You can use either a water-based acrylic paint or an oil-based paint, as long as the container identifies “for metal” somewhere on its labeling. Oil-based paints take much longer to dry, and they need a high-quality paintbrush that doesn’t shed during application.

What is the most durable metal coating?

Epoxy coatings are one of the most widely used steel coatings in industrial and marine markets. Epoxies are known for having excellent adhesion to steel and provide good chemical resistance. They are also often sold as “surface tolerant”, which means they will adhere well to surfaces with minimal surface preparation.

What is heavy duty coating?

MORE INFO. Total Coat Heavy Duty is a water based, plastic coating formulated to withstand abrasion and corrosion in automotive, industrial and agricultural environments. It can be applied on clean bare metal, primed, painted or top coated surfaces.

Which metal coating is best?

The galvanizing process has multiple advantages that make it a popular choice for numerous applications. For example, the zinc oxide coating is highly stable and adheres tightly to the metal substrate; it is very durable and does not flake off easily. Galvanizing is also renowned for its galvanic protection.

Which metal is used for steel coating?

Zinc: One of the most common and inexpensive protection methods for steel is provided by zinc. Zinc-coated, or galvanized, steel is produced by various hot-dipping techniques, but more steel companies today are moving into electrogalvanizing so they can provide both.

What are organic coatings?

An organic coating is a type of coating formed by carbon-based polymeric chains derived from natural (vegetable, animal) or synthetic matter. Solid, adhesive and cohesive organic coatings can be found in the form of paints, varnishes, lacquers.

What are the types of thermal spraying?

- HVOF (High Velocity Oxy-Fuel Spraying) HVOF is a process which makes use of a torch that allows the flame to spread whenever the nozzle is used. …

- Combustion Flame Spraying. …

- Plasma Spraying. …

- Vacuum Plasma Spraying. …

- Two-Wire Electric Arc Spraying.

Where is thermal spraying used?

Thermal spray coatings are extensively used in the manufacturing of gas turbines, diesel engines, bearings, journals, pumps, compressors and oil field equipment, as well as coating medical implants.

What is the most commonly used form of thermal spraying?

Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significantly, allowing the coating of flammable substances.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

What is a spray welder?

Spray welding is a term used to classify several welding procedures in the form of thermal spraying. It is an industrial activity that involves atomizing and spraying a powder or wire onto a metal surface at a high velocity with compressed gas.

What is chemical spray?

[′kem·i·kəl ′sprā] (ordnance) Aerial release, or device for aerial release, of liquid war gas for casualty effect, or of liquid smoke for aerial smoke screens.

What is spray coating method?

Spray coating is a technique in which the printing ink is forced through a nozzle whereby a fine aerosol will be formed [25]. In a spray coating process, characteristic performance of polymer solar cells is limited by some drawbacks such as isolated droplets, non-uniform surface and pinholes [10], [47].

What is the purpose of surface coating?

Surface coatings include paints, drying oils and varnishes, synthetic clear coatings, and other products whose primary function is to protect the surface of an object from the environment.

What is plasma spray coating?

Plasma spray is a thermal spray coating process used to produce a high quality coating by a combination of high temperature, high energy heat source, a relatively inert spraying medium, usually argon, and high particle velocities.

What is thermal spray used for?

Thermal spraying is a technology which improves or restores the surface of a solid material. The process can be used to apply coatings to a wide range of materials and components, to provide resistance to: Wear, erosion, cavitation, corrosion, abrasion or heat.