Centrifugal pumps are considered to be less destructive to blood elements (1) when compared to roller pumps. However, their large prime volumes render them unsuitable as arterial pumps in heart lung machine (HLM) circuitry for children.

What are skid sprayers used for? V-Series skid sprayers are available in sizes from 50 through 300-gallon and are commonly used for commercial lawn care, tree spraying, pest control and many other applications.

What is a roller pump on a sprayer? Roller Pumps are reliable and durable pumps that perform spraying and fluid transfer applications. The pumps available are offered in a wide range of flow rates, allowing models to exist for both lower and higher pressure applications.

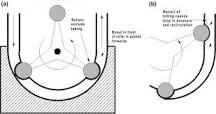

How does a hypro roller pump work? The pump operates by receiving a fluid through the inlet port where it is captured and transported by the rollers, and then expelled through the outlet port.

How does a piston pump sprayer work? Piston sprayers include a cylinder housing in which, when pumping, a piston moves up and down to create pressure. Most piston models can reach up to 90 psi. Higher psi delivers smaller droplet size and has a further reach. Use with low abrasive, low viscosity spray liquids such as herbicides and insecticides.

How long do roller pumps last?

| Availability | In Stock Online |

|---|---|

| Mix Rate | Ready to use. |

| Shelf Life | Hypro 6500XL-R Silver Series Roller Pump will last for 3 years in storage when kept in a dry, clean location. |

| Yield | Hypro 6500XL-R Silver Series Roller Pump can be used on one spray rig or power sprayer. |

| Use Sites | Outdoors |

What is the difference between roller pump and centrifugal pump? – Related Questions

How do you size a roller pump?

The flow required for agitation is a little easier as that is determined by tank size. For a 500-gallon tank you’re looking at 25gpm, 750-gallon tank will be 37 gpm, 1,000-gallon tank at 50 gpm and 1,500-gallon tank at 75 gpm. 3.) Choose the pump based on the manufacturer’s catalog performance charts.

How do you take apart a roller pump?

What is the reason of selecting roller pump in bypass machines over the more effective centrifugal pumps?

Cardiopulmonary Bypass and Management The two pumps used most commonly for CPB are roller pumps and centrifugal pumps. Roller pumps have the advantages of simplicity, low cost, ease and reliability of flow calculation, and the ability to pump against increased resistance without reducing flow.

What’s better a diaphragm or a piston pump sprayer?

Piston – A piston pump is the better option when spraying anything at a distance, such as trees and bushes, because of its higher pressure. They are normally a little less expensive and easier to repair. However, they aren’t as durable as a diaphragm pump.

What is the difference between a piston and diaphragm sprayer?

How does a pressure sprayer work?

How do I know if my roller pump is bad?

Rollers: Much like the rotor, undersized or swollen rotors in both length and diameter are not good. Measure the thickness and make sure it’s no smaller than 1.4995. Any smaller and it may be worn out and need to be replaced. Oh and make sure you replace rollers as a set, not just one at a time.

How do you size a sprayer pump?

- Know your pump’s overall intended use; e.g. Boom sprayer fertilizer application; Water delivery; Herbicide irrigation;

- Know any specific pump needs for the job; e.g. Pressure need for vertical, horizontal clearance; High capacity GPM flow for water, de-watering, transfer;

Can you use a transfer pump for a sprayer?

Transfer pumps, in particular, are widely used for spray equipment and can help you tackle both the simplest and toughest of spraying jobs.

Who invented roller pump?

Mechanical circulatory support got its start in 1934 when Dr Michael DeBakey developed the concept of a roller pump to facilitate blood transfusions. Twenty years later Dr John Gibbon, along with a team of five engineers from IBM, created the first cardiopulmonary bypass machine.

What is cavitation in centrifugal pump?

Cavitation occurs in centrifugal pumps when the Nett Positive Suction Head Available (NPSHa) is lower than the Nett Positive Suction Head Required (NPSHr) causing the formation and accumulation of bubbles around the impeller eye that then collapse resulting in a series of mini implosions and significant damage to both …

How does centrifugal blood pump work?

Centrifugal pumps act through a spinning rotor to generate blood flow. This technique avoids high pressures in the case of distal circuit occlusion, but it may induce shear stress and turbulence to blood cells that may lead to hemolysis and thromboembolic complications.

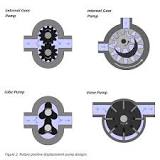

What type of pump is a roller pump?

A peristaltic pump, also commonly known as a roller pump, is a type of positive displacement pump used for pumping a variety of fluids. The fluid is contained in a flexible tube fitted inside a circular pump casing.

What is positive displacement pump?

What is a positive displacement pump? A positive displacement (PD) pump moves a fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes.

What are the types of blood pumps?

Comparison of the four types of blood pumps being developed to provide circulatory support. A, Pneumatic ventricular assist pump; B, pneumatic artificial heart; C, motor-driven ventricular assist pump; D, motor-driven artificial heart.

How do agricultural sprayers work?

How does a backpack pump sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How does a diaphragm sprayer work?

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.