In spray dryers, atomizer system is much like a knife that needs to cut fluid particles precisely into finar parts, and if the automizer fails, it can have serious consequences. Atomization system works to chop up the liquid droplets into even finer droplets in order to serve the higher surface area to volume ratio.

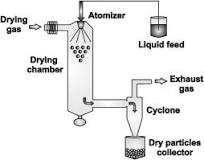

What is spray dryer how it works? A spray dryer takes a liquid stream and separates the solute or suspension as a solid and the solvent into a vapor. The solid is usually collected in a drum or cyclone. The liquid input stream is sprayed through a nozzle into a hot vapor stream and vaporized. Solids form as moisture quickly leaves the droplets.

How can I increase the yield of my spray dryer? Decreasing the liquid pumping rate, increasing the atomising air flow rate and the dry air flow rate can all help to increase the yield (Maury et a l, 2005) . …

How many types of spray dryers are there? … Among them are the rotary, nozzle, two-fluid, pressure and ultrasonic nozzle (Walzel, 2011). Atomization is a crucial part of the spray dryer because it influences the drying rate, particle diameter, particle distribution, and dispersibility of the powder for rehydration (Chegini & Taheri, 2013) .

What is residence time in spray dryer? Typical residence times in a chamber are 12 to 30 seconds. Due to the evaporative cooling effect, the inlet temperature on this type of dryer is normally quite high relative to the dry products’ temperature limitations. Typical inlet temperatures for spray dryers range from 400°F to 1000°F depending on the application.

What is the difference between a dryer and a spray dryer? For many thermally-sensitive materials such as those used in the food and pharmaceutical industries, this is the preferred drying method. Spray dryers can dry very quickly compared to other methods. They also turn a liquid into a dried powder in a single step, which simplifies and improves profit margins.

What is atomizer in spray dryer? – Related Questions

What are the advantages of spray drying?

Benefits of Spray-Drying Some of the advantages of spray-drying include its ability to be fully automated and continuous. Short residence times and suitability for both heat-sensitive and heat-resistant foods are other advantages. The technology is suitable for a variety of feed materials, provided they are pumpable.

What is thermal efficiency in spray drying?

It was reported that the heat efficiency of spray dryer is about 25% to 60%, and some even are below 20%[1]. The above results show that the heat consumption of spray drying is a large cost, generally speaking, the heat consumption accounts for 60% of the total cost.

What is the size range of particle produced from spray drying?

The droplets lose moisture rapidly and dry when they meet a stream of hot gas. The drying occurs in an insulated chamber. Powders produced have relatively uniform characteristics and are collected from the spray dryer. Spray drying usually provides particles with a mean particle size below 10 μm, preferably 5 μm.

How do you determine the efficiency of a dryer?

Thus if dryer efficiency ηis expressed as latent heat of evaporation divided by actual heat supplied to the air, this is (103/130) or approximately 80%, so that 20% is inherently lost in the exhaust. This efficiency will vary with inlet air temperature, falling further for lower inlet temperature.

What is the main difference in using single two and three stage spray dryer?

Two Stage Spray Dryer – spray dryers followed by fluid bed dryer for drying products which require longer residence time & product conditioning post drying. Three Stage Spray Dryer – spray dryers with Internal fluid bed followed by external fluid bed dryer for producing dust free agglomerates.

Who invented spray dryer?

Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [1, 2, 3]. Ever since it was first discovered, the spray-drying technique has been improved concerning its operational design and applications.

What may be the factors affecting spray drying?

Scope and approach: Product yield and physical properties of the final powder are affected by various factors, including carrier material and its concentration added into the feed, feed flow rate, atomization speed/pressure, and drying temperature.

Which product is not dried by a spray dryer?

| Q. | Which product is NOT dried by spray dryer? |

|---|---|

| B. | Fruit Juice |

| C. | Lactose |

| D. | Bacterial & viral cultures |

| Answer» d. Bacterial & viral cultures |

What is the difference between spray drying and freeze drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

What is spray dry technology?

Spray-drying is a rapid, continuous, cost-effective, reproducible and scalable process for the production of dry powders from a fluid material by atomization through an atomizer into a hot drying gas medium, usually air.

What are the spray dryer parts and function?

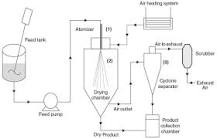

A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. The three stages that occur in a spray dryer before drying is accomplished include: Atomization. Spray-air mixing and moisture evaporation.

What are the advantages of spray?

Spray paint offers more even coverage without brush strokes. Spray primer is a million times faster than brush primer. Spray paint is a million times faster than brush on paint. Spray paint is typically oil based, therefore more durable than water based spray or regular latex paint.

Which dryer has the least thermal efficiency?

The lowest SEC was recorded at 17.44 kWh/kg using gas dryers, while a maximum SEC (112.05 kWh/kg) was observed at the electric dryer under 60 °C and 2.0 m/s. The gas dryer had a thermal efficiency ranging from 50.32 to 78.77%, while the electrically heated dryer had a thermal efficiency ranging from 34.86 to 50.34%.

Which solar dryer is more efficient?

Vishnuvardhan and Chandramohan (2020), found that the performance of forced convection indirect solar dryer is better than the natural convection indirect solar dryer in terms of collector and drying efficiencies.

How do you calculate drying time?

A simple way to calculate is: m = (WW-DW) / WWx100%, WW: wet weight, and DW: dry weight. Dry basis moisture content is the ratio of water to the dry weight of material: M = 100 (Wm / Wd) = 100m / (100-m).

What types of dryers are there?

- Standard vented dryers. A heating element raises the temperature of the air in the dryer and the moisture from the wet clothes is vented through aluminum ducts. …

- Ventless dryers. …

- Condenser dryers. …

- Heat pump dryers.

What are the components of spray dryer?

- feed pump.

- atomizer or spray nozzles.

- air heater, air disperser.

- drying chamber.

- powder recovery systems.

- process control systems.

- Click here to learn the specifications of PacMoore’s spray dryers.

What is spray dry technology?

Spray-drying is a rapid, continuous, cost-effective, reproducible and scalable process for the production of dry powders from a fluid material by atomization through an atomizer into a hot drying gas medium, usually air.

What are spray dried products?

- Milk.

- Egg products.

- Fruit juices.

- Beverages.

- Starch and derivatives.

- Tea and coffee.

- Cereals and spices.

- Flavors and colors.