How do you make a boom sprayer?

How high should a spray boom be? This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

How many PSI is a boom sprayer? Generally, the operating pressure for a typical boom-sprayer ranges from 15 to 80 psi. Most nozzles tend to produce a greater volume of spray in finer droplets at higher operating pressures.

What is a boom spray used for? A boom sprayer is the most common type of apparatus for applying herbicides in broadscale farming. A sprayer has many components, the most important being the nozzles, which split the herbicide into many small droplets that are projected through the air to the target.

How do you make a ATV boom sprayer?

How are spray nozzles calculated? – Related Questions

How do you calibrate a sprayer boom?

- Select a travel distance from Table 1 based on row spacing. …

- Drive 136 feet and measure the time in seconds.

- If it took 15 seconds, catch the output from each of the three nozzles for 15 seconds. …

- Repeat Step 3 for each set of nozzles on the boom to make sure the application rate is uniform across the boom.

Which nozzle is best for herbicide spray?

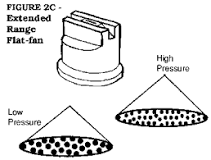

Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides.

What are the 2 types of nozzles?

The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

What pressure should I run my sprayer at?

Running from 40-80 PSI usually. As crw said, the controller will try to match the pump to your ground speed by changing the speed of the pump. That will of course affect the pressure at the nozzles. Lower pressures should mean courser droplets, high pressure = finer droplets.

How big of pump do I need for my sprayer?

For boom spraying we would recommend the seven gallon per minute pump which will give you good pressure and flow for a small to medium sized boom.

What pressure should sprayer be set at?

Depending on the type of spray tip installed, a pressure range (at the spray tip) of 10 to 30 pounds per square inch (psi) is usually appropriate for herbicides, while a range of 30 to 50 psi is most often appropriate for insec- ticides and fungicides.

Why is it called a boom sprayer?

What is Boom Spraying? A Boom Sprayer usually has multiple spray nozzles (tips are usually the American terminology) spread out along arms (booms), pointed directly down.

What are the types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What are different types of sprayers?

- Knapsack Sprayer.

- Portable Power Sprayer.

- Knapsack Power Sprayer.

- Mist Dust Sprayer.

- HTP Sprayers.

- Orchard Sprayers.

How do you make a homemade sprayer?

How do Boomless spray nozzles work?

A boomless sprayer generally has one or two nozzles that can be pointed out sideways or tilted slightly up and spray out further achieve coverage. A boom sprayer typically has multiple spray tips spread out along both boom arms with even spacing and are pointed straight down towards the target.

How do you make a tank sprayer?

How many gallons does it take to spray an acre?

Answer: On average, 1 gallon of mixed solution will cover about 1000 sq/ft, so it would take you about 44 gallons to cover an entire acre.

How many acres will a 100 gallon sprayer cover?

The sprayer holds 100 gallons, so 100 gallons ÷ 20 gal/acre = 5 acres that can be covered with each tank.

How many acres will a 25 gallon sprayer cover?

With a 25-gallon sprayer, you can expect to cover two acres.

How many nozzles does a boom sprayer have?

Five nozzles can produce the required flow, each at different pressures.

How do I choose a nozzle size?

The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

What do the numbers on spray nozzles mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

Do nozzles increase pressure?

In a convergent nozzle, there is an increase in velocity and a decrease in pressure, but we know that pressure is inversely proportional to area.

How many types of spray nozzle are there?

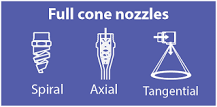

There are 5 basic spray pattern types: flat fan, solid stream, full cone, hollow cone and mist/fog.

What are the types of nozzle used in sprayer?

Nozzle Description. Nozzle types commonly used in low-pressure agricultural sprayers include flat-fan, flood, raindrop, hollow-cone, full-cone, and others. Special features, or subtypes such as “extended range,” are available for some nozzle types.

What is a wet boom?

A wet boom has a rigid pipe usually stainless, with holes in it for the fittings spaced every 15-30 inches. A dry boom is fittings with flexible hoses connecting to each fitting.

How do you use a nozzle chart?

On a standard nozzle chart, the top column that runs left to right is the pressure that you want to obtain. The left column top to bottom is the nozzle orifice size designation. The top to bottom column next to the orifice size column indicates the actual orifice measurement.

How do you make a water tank sprayer?

How do you make a paint sprayer?

What is a dry boom sprayer?

A dry boom is effectively a sprayer boom that is fed only by hoses, and does not include any liquid filled boom pipe. Conversely, a boom that is fed by pipe/tube is generally referred to as a “wet boom”.

How do you make a spray bottle out of a plastic bottle?

Make sure the spray cap is unscrewed from the bottle. Then, slice the plastic in a circle about 2 cm (0.79 in) away from the mouth to remove it from the bottle. You don’t have to cut around the mouth in a perfect circle — just try to make the width roughly the same all the way around.