HTS Code 8422.30 – Machinery for filling, closing, sealing or labelling bottles, cans, boxes, bags or other containers; machinery for capsuling bottles, jars, tubes and similar containers; machinery for aerating beverages.

How much does a filling machine cost? Some of the smaller machines will run anywhere from $1500 to $2500. These are the machines that do not have a large output and may be a good choice for a small company that does not have large production needs. Larger filling machines can run anywhere from $8000 to over $100,000 depending on the company’s needs.

How do you fill an aerosol can?

What is automated filling machine? Automatic Filling Machine. An automatic filling machine guides, organizes, fills, and then releases bottles in an automatic bottle packaging line, such as a filling, capping, and labeling line.

What is a fill machine? Fillers (or filling machines) are used for packaging, mainly for food/beverage but for other products as well. These are used to fill either a bottle or a pouch, depending on the product. There are several types of fillers used by the packaging industry.

What is a capping machine? A capping machine’s main function is to apply a metal or plastic thread lid, snap, or caps accurately and securely to a container or bottle. Capp closing machines also process plugs and other similar closures. These systems ensure sanitary workspaces, high production speeds, and affordable manufacturing costs.

Can filling machine HS Code? – Related Questions

What is the gas in aerosol cans?

Aerosol food products generally use nitrous oxide or carbon dioxide as the propellant, while other substances (pharmaceuticals, paints and cosmetics) use flammable hydrocarbons. Cans. Aerosol cans are leakproof and made from aluminium or steel.

What pressure is in an aerosol can?

Typically, the contents of an aerosol are stored at 2–8 times normal atmospheric pressure (and usually the lower end of that range).

How do you make aerosol cans at home?

How does a vacuum filler work?

How it works: When Filling nozzle inserted into an empty bottle, the sealer seals the bottle and air in the bottle is pulled out by vacuum pump. The vacuum in the bottle then sucks liquid into the bottle.

How does a vacuum bottle filler work?

Vacuum level semi-automatic filling machines use the rim at the top of the container to form an airtight seal around the filling nozzle. This airtight seal creates a vacuum within the bottle which draws free-flowing liquids from a supply tank into the bottle, via specially designed nozzles.

What is bottle filling?

Bottle filling is a delicate part of packaging liquids and other substances. It can be performed in different ways based on the type of beverage (sparkling or still) or substance (detergents, oil, liquors) to be packaged, and on the packaging type being used (PET or glass bottles, cans, Tetra-packs etc.).

How many types of filling machines are there?

The main types of powder filling machines include vacuum powder filling machines, bulk powder filling machines,capsule powder filling machines, auger filling machines, net weight filling machines, scale powder filling machines etc.

How do you make a filling machine?

What is volumetric filling machine?

Volumetric filling machines are used to deposit specific product portions into packaging materials such as containers, packets and the like. Focused on hygiene, accuracy and efficiency, these machines can improve your packaging processes substantially.

What is a product HS Code?

HS code is short for Harmonized Commodity Description and Coding System. It’s a list of numbers used by customs to classify a product.

What is the HS code for packaging material?

| HS Codes Heading | |

| Heading Codes | Heading Description |

|---|---|

| 4819 | HS Codes of Cartons, boxes, cases, bags and other packing containers, of paper, paperboard, cellulose wadding or webs of cellulose fibres; box files, letter trays, and similar articles, of paper or paperboard of a kind used in offices, shops or the like |

What is the HS Code for air compressor?

HS Code 84144010 – Air, compressors, mounted.

What is the most common aerosol propellant?

The most common form of aerosol can propellant is a liquefied gas like butane, isobutane, or propane. The gas is turned into liquid by pressurizing it within the can. The advantage of this system is that it provides constant pressure levels throughout the life of the can.

Why people must not use aerosol sprays?

Many aerosol sprays contain highly toxic chemicals like xylene and formaldehyde – yes the same chemical used to preserve anatomical specimens in a jar. These toxic ingredients also include neurotoxins and carcinogens that are extremely hazardous for adults, children and family pets.

What is used to pressurize spray cans?

Pressurized by liquefied gas, which gave it propellant qualities, the small, portable can enabled soldiers to defend themselves against malaria-carrying mosquitoes by spraying inside tents and airplanes in the Pacific during World War II.

Why do aerosol cans stop working?

If a spray paint can is in constant use on a regular basis, the cap and nozzle can become blocked. Simply removing the blockage can be all it takes to get your coloured spray can working again. Here are a few things that you can do to help unblock a spray paint can: Shake the can well before use.

Is aerosol a gas or liquid?

Aerosol is defined as a suspension system of solid or liquid particles in a gas. An aerosol includes both the particles and the suspending gas, which is usually air.

How do you make a refillable compressed air can?

Can you refill spray paint cans?

You don’t have to throw away that empty spray paint can that worked perfectly. Instead, you can refill the paint can by transferring paint from another can of paint.

What is Preval Sprayer?

The Preval Sprayer is an aerosol-based spray system that allows the user to mix up any paint, chemical or solution and turn it in to sprayable material through Preval’s patented Venturi Vacuum Process.

How does a spray can nozzle work?

Pressing the nozzle of the can changes the air pressure inside which causes the liquefied gas to boil and become a vapor. Pressing the nozzle also siphons gas through the nozzle hole, releasing the vaporized paint and creating the “spray” effect.

How do you Repressurise a can?

Nope. The fix is real simple: take the can and a rubber-tipped air sprayer, and use your air compressor to repressurize the can.

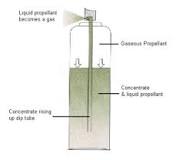

How do aerosol bottles work?

When the liquid mixture is released from the aerosol, the liquid propellant becomes a gas and helps break up the product into a fine mist. In foams like mousse and aftershave, the liquid gas forms bubbles, making the product expand as it is released from the aerosol.

How do pressurized cans work?

It is the small valve at the top of the can. When you press the nozzle, it opens the valve, reducing the amount of pressure allowing the contents to escape in a controlled and measured manner. Once you have released the button, the valve closes up again and contains the materials and pressure within the can.