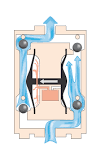

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of a housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

How do you fix a solo sprayer?

What is the difference between a piston and diaphragm sprayer?

How do you disassemble a solo 475?

Why is my pump sprayer not working?

How does a diaphragm sprayer pump work? – Related Questions

Why does my solo sprayer leak?

Possible Causes for Leaks The most common reason sprayers leak is a worn or damaged component, whether that be a valve or an O-ring. To fix a leaking sprayer, you need to locate the source of the leak.

What is better piston pump or diaphragm pump?

Piston pumps work best with lighter chemicals, such as herbicides and insecticides. Diaphragm – Diaphragm pumps don’t deliver as much pressure as piston, making them ideal for use in close application scenarios such as weed killing. But the diaphragm pump is more durable to chemical damage.

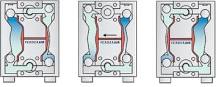

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

What is a linear diaphragm pump?

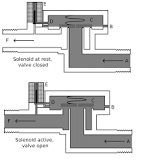

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

Do diaphragm pumps need to be primed?

Diaphragm Pumps Are Self-Priming Unlike some other pumping technologies, AODD pumps are self-priming and don’t require positive inlet pressure to prime (flooded or needing a dry suction lift).

Do diaphragm pumps need lubrication?

And when your equipment performs with the versatility and durability that your application demands, you can keep things running smoothly. Air operated diaphragm pumps are rugged, lube-free, non-stall/freeze pumps that provide the high quality, trouble-free, continuous output—even under the toughest conditions.

Where are Solo sprayers manufactured?

In Australia, we are the sole distributor of SOLO products, which are manufactured in Germany. A world-leader in two-stroke technology, SOLO produce garden and rural products for spraying pesticides and weed control agents.

How do you open a stuck pump sprayer?

Push the pump handle all the way down and turn counter clockwise into the locked position. Continue to turn the pump handle counter clockwise until the entire lid starts to turn and unscrew. This can be difficult sometimes if the lids are put on very tight.

How do you store a solo backpack sprayer?

Before winter, thoroughly drain the tank, pressure cylinder, and hose. Then, store the sprayer with the shut-off valve in the open position to prevent damage from freezing.

How do you prime a sprayer pump?

How do you fix a spray bottle pump mechanism?

Can you leave roundup in sprayer?

Can You Leave Weed Killer in a Sprayer? Yes, you can. However, it does depend on the amount of time you are leaving it there. If there is an interruption due to weather, it is okay to leave the chemicals in the tank, provided you resume spraying after a few hours.

How does a solo sprayer work?

How do you maintain a backpack sprayer?

Backpack Sprayer Maintenance Check filter before every use. – Clean out the backpack. Debris and chemicals can build up in tank, pump, hoses, tips, etc. Clean out the tank periodically and flush the sprayer with clean water.

Why is my knapsack sprayer not working?

If you are experiencing lost or low pressure on your sprayer, check to see if the filter in the backpack is clogged. Some clogs can be fixed as easily as spraying water into the empty backpack to flush out the filter. Rinse out the tank a few times and see if that fixes the problem.

What type of pump is a diaphragm pump?

A diaphragm pump (also known as a Membrane pump) is a positive displacement pump that uses a combination of the reciprocating action of a rubber, thermoplastic or teflon diaphragm and suitable valves on either side of the diaphragm (check valve, butterfly valves, flap valves, or any other form of shut-off valves) to …

Is the human heart a diaphragm pump?

The volume is a constant given each cycle of operation. The human heart is also a good example of a positive displacement pump because it works on the principle of a diaphragm pump.

Is the heart a diaphragm pump?

Both are considered reciprocating pumps, however, the end of the plunger in a diaphragm pump is connected to a flexible diaphragm that flexes back and forth. The human heart, for example, is a type of naturally occurring diaphragm pump.

What are the disadvantages of a diaphragm pump?

- They have little pulsation which may lead to the device damage.

- These pumps are persuaded not to push very accurately at their base section.

- Many of the diaphragm pumps typically need 20 cubic feet for every minute & nearly 100 PSI of air consumption to function efficiently.

Can a diaphragm pump pull a vacuum?

Modern multi-stage diaphragm pumps can provide vacuum levels throughout the entire rough vacuum range (atmosphere to below 1 mbar/torr) providing vacuum levels suitable for many tasks. Standard models can perform degassing of liquids, and even be used as backing pumps for wide range turbomolecular pumps.

Do diaphragm pumps create suction?

The number one diaphragm causes a press stroke moving liquid out of the pump. At the same time diaphragm number two is performing a suction stroke. The air behind diaphragm number two is being pushed out to the atmosphere causing atmospheric pressure to push the liquid to the suction side.

How do linear pumps work?

Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

What is linear pump?

Linear peristaltic pumps transport fluid through a flexible duct using traveling contraction waves. In a typical linear peristaltic pump, discrete translational elements rhythmically compress a straight section of flexible tube, moving fluid volumes.

How does a linear air compressor work?

Linear compressors work similarly to a solenoid: by using a spring-loaded piston with an electromagnet connected to AC through a diode. The spring-loaded piston is the only moving part, and it is placed in the center of the electromagnet.

How do I fix my hand sprayer?

How do you take apart a pump sprayer?

How do you put together a solo backpack sprayer?

Why is my knapsack sprayer not working?

If you are experiencing lost or low pressure on your sprayer, check to see if the filter in the backpack is clogged. Some clogs can be fixed as easily as spraying water into the empty backpack to flush out the filter. Rinse out the tank a few times and see if that fixes the problem.