Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [1, 2, 3]. Ever since it was first discovered, the spray-drying technique has been improved concerning its operational design and applications.

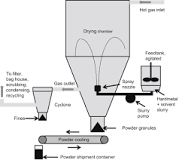

How does a milk spray dryer work? The main principle employed when producing milk powder with a spray dryer is the atomization of concentrated milk. The concentrated milk is disintegrated in an extensive chamber. The milk concentrate is passed through heated air. During this process, the evaporator cools down the thin milk droplets.

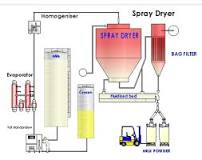

Can milk be spray dried? Spray drying is one of the most convenient techniques for producing milk powders and for stabilising milk constituents. Before spray drying, the milk undergoes several processes (such as heat treatment, cream separation, membrane processes, vacuum evaporation and homogenisation).

What is spray drying milk? Spray drying is a major process of water removal and particle formation in milk powder production. The principle of spray drying is to remove the water from the milk concentrate as fast and at as a low temperature as possible so as to minimize heat damage to the milk solids.

Which dryer is used for milk drying?

We also know that the drum dryer and the spray dryer are the two common types of dryers used for drying liquid foods. Thus, they are used also for drying of milk.

What are the advantages of spray dryer? Benefits of Spray-Drying Some of the advantages of spray-drying include its ability to be fully automated and continuous. Short residence times and suitability for both heat-sensitive and heat-resistant foods are other advantages. The technology is suitable for a variety of feed materials, provided they are pumpable.

Who invented spray dryer? – Related Questions

What is the difference between a dryer and a spray dryer?

Spray dryers can dry a product very quickly compared to other methods of drying. They also turn a solution (or slurry) into a dried powder in a single step, which simplifies the process and improves profit margins.

How do you make powdered milk with a spray dryer?

For getting the powder, the liquid milk is converted into a milk concentrate or suspension. This concentrate when dried with the spray of hot air, leaves behind the milk powder with subsequent evaporation and cooling. The process starts with setting the milk feed into the atomising device of the spray dryer.

How is spray dried milk powder made?

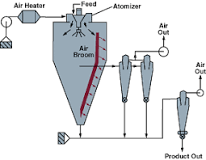

Concentrated milk and hot air (180-200°C) is sprayed into a drying chamber which is usually a stainless-steel jacket with a conical bottom by the help of an atomizer. The drying chamber is usually a stainless-steel jacket with a conical bottom, the drying gas dries the particle before it touches the chamber.

What is spray drying technique?

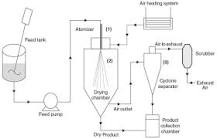

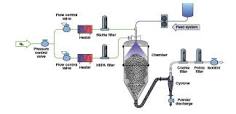

The spray drying process involves the atomization of a solution, slurry, or emulsion containing one or more components of the desired product into droplets by spraying followed by the rapid evaporation of the sprayed droplets into solid powder by hot air at a certain temperature and pressure.

What is the difference between spray drying and freeze drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

Is infant formula spray dried?

Powdered infant formula is generally manufactured via dry blending or wet blending with subsequent spray drying. In the spray drying process the pasteurized and homogenized liquid is atomized in the spray dryer chamber.

What are the types of spray dryers?

… Among them are the rotary, nozzle, two-fluid, pressure and ultrasonic nozzle (Walzel, 2011). Atomization is a crucial part of the spray dryer because it influences the drying rate, particle diameter, particle distribution, and dispersibility of the powder for rehydration (Chegini & Taheri, 2013) .

Can we make milk powder at home?

Pour the milk into a large pan. Then, preheat the oven at 150°F and place the pan in it. Leave the oven slightly open so that the moisture gets out. When the milk is dry, take it out of the pan and grind the pieces in a blender to make powder.

What is freeze dried milk?

Dairy Freeze Drying Process Freeze drying dairy products uses a process called lyophilization to gently freeze the product, then the water is extracted in the form of vapour using a high-pressure vacuum. The vapour collects on a condenser below the freezing chamber, returns to ice and is removed.

What temperature is spray drying?

The typical spray drying process used today employs air heated up to 400° Fahrenheit to dry an atomized liquid into a powder.

How efficient is spray drying?

The hot air is used as the drying medium in spray dryer. It was reported that the heat efficiency of spray dryer is about 25% to 60%, and some even are below 20%[1].

What is spray dryer machine?

Spray dryers are rapid dryer, drying rate is high. Product quality can be controlled and maintained in drying process. Highly controllable drying systems flow of hot air, droplet speed and droplet temperature can be effectively controlled. Fine droplets shaped offers more surface area for heat and mass transfer.

How can I increase the efficiency of my spray dryer?

Spray drying energy efficiency can be improved by widening the gap between inlet and outlet temperatures and adding heat recovery equipment. For many years, spray drying has been one of the most energy-consuming drying processes, yet it remains one that is essential to the production of dairy and food product powders.

What are the challenges in the spray drying process of milk powder?

Dairy powders pose stickiness problems at specific temperatures, relative humidity and water activity due to the presence of lactose and fat.

Which product is not tried by spray dryer?

| Q. | Which product is NOT dried by spray dryer? |

|---|---|

| B. | Fruit Juice |

| C. | Lactose |

| D. | Bacterial & viral cultures |

| Answer» d. Bacterial & viral cultures |

What is roller drying?

Drum Drying also known as Roll Drying is a continuous process that creates dry powders and flakes from a liquid feedstock. The liquid feed is sprayed onto or in between two rotating drums. The drums are heated internally with steam to increase the surface temperature.

Which dryer is used in solid material?

Freeze dryers. Freeze-drying is an extreme form of vacuum drying in which the water or other solvent is frozen and drying takes place by subliming the solid phase.

Which milk is preserved by the addition of sugar?

CONCENTRATED MILK PRODUCTS | Sweetened Condensed Milk Sweetened condensed milk (SCM) is one of the oldest industrially produced dairy products. It is produced by removing most of the water from fresh cow’s milk and the addition of sugar; it is preserved by its sugar content, not by sterilization.

What are the disadvantages of powdered milk?

- It doesn’t taste like milk. The flavor of powdered milk is somewhat different than the flavor of regular milk. …

- It doesn’t have a lactose-free option. Since 1995, there has been at least one low-lactose powdered milk available to consumers. …

- It doesn’t always mix up as it should.

Is dry milk healthy?

Powdered milk has the same nutrition as fresh milk. It provides bone-building nutrients such as protein, calcium, vitamin D and vitamin A. Powdered milk is a source of protein and may be added to recipes to increase the amount of protein and energy (especially for people with health conditions that need extra protein).

What chemicals are used in milk powder?

According to USAID, the typical average amounts of major nutrients in the unreconstituted nonfat dry milk are (by weight) 36% protein, 52% carbohydrates (predominantly lactose), calcium 1.3%, potassium 1.8%.

What is spray dryer PDF?

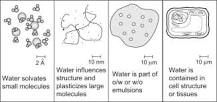

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.

What is spray drying in food preservation?

Spray drying is the process where a mixture of compounds is made in its liquid or slurry form that is finally converted into dry powder form. This drying technique emerged way back in 1860s and was used during World War II. It helped to make easy shipment of larger quantities of food within limited storage area.

Why maltodextrin is used in spray drying?

Spray drying technique is also appropriate for heat sensitive components. Maltodextrin, gum arabic and gelatin are successfully used as drying aids to facilitate drying. Maltodextrin is one of the common drying aids for spray drying owing to its beneficial role as a carrier or an encapsulating agent.

How is spray dried milk powder made?

Concentrated milk and hot air (180-200°C) is sprayed into a drying chamber which is usually a stainless-steel jacket with a conical bottom by the help of an atomizer. The drying chamber is usually a stainless-steel jacket with a conical bottom, the drying gas dries the particle before it touches the chamber.

What is spray drying technique?

The spray drying process involves the atomization of a solution, slurry, or emulsion containing one or more components of the desired product into droplets by spraying followed by the rapid evaporation of the sprayed droplets into solid powder by hot air at a certain temperature and pressure.

What is drum drying of milk?

After the concentration stage, the concentrated milk with a dry solids content of 40-45% is fed to the drum dryer. The milk is further concentrated in the sump between two drums and then adheres to the rotating drums. After almost one rotation, the dried product film – as a sheet of paper – is scraped off by the knive.

What is the difference between drying and evaporation?

Drying, or dehydration, is used to remove relatively large amounts of water from foods, and is accomplished by imposing a difference in water activity between the food and its surroundings. Evaporation is used to concentrate liquid foods, as water in the food reaches the boiling point and escapes into the surroundings.