When it comes to sprayers powered by internal combustion engines, power sprayers are the most common type. These machines are widely used in agriculture and other applications where high pressure and mobility are essential. They typically feature a small engine that drives a pump, allowing for efficient spraying of liquids like pesticides, herbicides, and fertilizers.

Types of Sprayers with Internal Combustion Engines

Power Sprayers

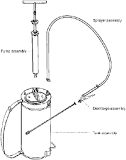

Power sprayers are designed for agricultural use and are often portable. They consist of several key components:

- Prime Mover: This is usually an internal combustion engine that provides the necessary power.

- Tank: Typically made from plastic to prevent corrosion, these tanks hold the liquid to be sprayed.

- Agitator: Ensures that the liquid remains mixed, which is crucial for effective spraying.

- Air Chamber: Helps maintain consistent pressure during operation.

- Pressure Gauge and Regulator: These components allow the operator to monitor and adjust the spray pressure as needed.

- Nozzles: Breaks the liquid into droplets for even distribution.

Engine-Driven Pressure Sprayers

These sprayers are specifically designed for tasks like soft washing and applying chemicals. They often come with features such as adjustable pressure regulators and integrated pressure accumulators.

Wheelbarrow Tank Sprayers

These portable units are equipped with a tank mounted on a wheelbarrow frame, making them easy to transport. They usually feature a diaphragm pump powered by a small petrol engine.

Benefits of Using Internal Combustion Engine Sprayers

- Mobility: These sprayers can be easily moved around fields or job sites without needing electrical outlets.

- Power: They can generate high pressure, making them effective for a variety of spraying tasks.

- Versatility: Suitable for different applications, from agriculture to cleaning.

FAQ

What types of fuels do internal combustion engine sprayers use?

Most internal combustion engine sprayers operate on petrol or diesel fuels. The choice depends on the specific model and application.

How do I maintain my internal combustion engine sprayer?

Regular maintenance includes checking oil levels, cleaning air filters, and ensuring that the fuel system is free from debris. It’s also important to inspect hoses and nozzles regularly for wear.

Are there any environmental concerns with using these sprayers?

Yes, there can be environmental impacts due to emissions from combustion engines. Using these sprayers responsibly and following local regulations can help mitigate these effects.

In conclusion, internal combustion engine-operated sprayers are essential tools in various fields due to their power and mobility. Whether you’re in agriculture or need a robust cleaning solution, these machines offer reliable performance for your spraying needs.