The motor type used on most hydraulic pump drives is the 3-phase, squirrel cage, induction motor, of integral HP in therange of 1 to 500 HP.

How does Hydraulic Pump work? Hydraulic pumps convert electrical energy into fluid pressure by using an electric motor to drive the pump. They are necessary for all hydraulic drives. The fluid pressure is then delivered by hydraulic fluid to cylinders and actuators and hydraulic motors at the required pressure level and volume.

Can you use a Hydraulic motor as a Pump? Hydraulic motors are powered by pressurized hydraulic fluid and transfer rotational kinetic energy to mechanical devices. Hydraulic motors, when powered by a mechanical source, can rotate in the reverse direction, and act as a pump.

What is a sprayer pump? Sprayer pumps are widely used in agriculture spraying systems, liquid transfer, and water applications. Pumps have evolved around industry and application specific uses with a variety of features. Some of the uses for sprayer pumps include: Agricultural Booms, Boomless Spray Nozzles and Field Sprayers.

How do sprayer pumps work? A spray-bottle head is made up of only a few parts. It has a trigger lever, which activates a small pump. This pump is attached to a plastic tube that draws cleaning fluid from the bottom of the reservoir. The pump forces this liquid down a narrow barrel and out a small hole at the gun’s muzzle.

What are the main types of hydraulic pumps?

- Gear pumps.

- Piston pumps.

- Rotary vane.

- Screw pumps.

Which motor is used in pumps? – Related Questions

Which pump is used in hydraulic system?

There are two types of hydraulic pumps to consider: gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps.

What is difference between hydraulic motor and hydraulic pump?

In fact, the first difference between pumps and motors – and also the most important – is the function of the two components: pumps convert mechanical energy into hydraulic energy; motors, on the other hand, transform hydraulic energy into mechanical energy.

Whats the difference between a hydraulic pump and a hydraulic motor?

A hydraulic motor is a machine that uses hydraulic pressure to generate mechanical power. A hydraulic pump is a device that extracts energy from the hydraulic pressure to generate mechanical work.

What are 4 types of hydraulic motors?

There are four basic types of hydraulic motors: Gear-type motors (internal or external gears). Vane-type hydraulic motors. Radial-piston-type motors. Axial-piston-type hydraulic motors.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

How big of pump do I need for my sprayer?

For boom spraying we would recommend the seven gallon per minute pump which will give you good pressure and flow for a small to medium sized boom.

Can you use a transfer pump for a sprayer?

Transfer pumps, in particular, are widely used for spray equipment and can help you tackle both the simplest and toughest of spraying jobs.

Why is my pump sprayer not spraying?

What are the parts of sprayer?

- Wand.

- Nozzle.

- Control Locks.

- Pressure-Release Valves.

- Pump Handle with Flow Control.

- Hose or Tube.

- Pump.

- Sprayer Tank.

How do you fill a pump sprayer?

Which hydraulic pump is best?

- 1 | TRIC Tools. …

- 2 | Hammerhead Trenchless. …

- 3 | Power Team. …

- 4 | TT Technologies. …

- 5 | Pow-R Mole Trenchless Solutions.

What type of hydraulic pump is most efficient?

Volumetric pumps Each type of pump has its own advantages and disadvantages. Impulse pumps are the most efficient because they use less energy than displacement or volumetric pumps. Displacement pumps are the least efficient because they require more energy to move the same amount of fluid.

How do I choose a hydraulic pump?

- Hydraulic Fluid Viscosity. Fluid viscosity refers to the thickness of the liquid in your pump. …

- Fluid Type. …

- Flow Rate. …

- Power Curves/Torque Ratings. …

- Speed. …

- Max Operating Pressure. …

- Fixed Displacement Vs. …

- Maintenance Time and Costs.

What are 3 types of fluid pumps?

There are three basic types of pumps: positive-displacement, centrifugal and axial-flow pumps. In centrifugal pumps the direction of flow of the fluid changes by ninety degrees as it flows over an impeller, while in axial flow pumps the direction of flow is unchanged.

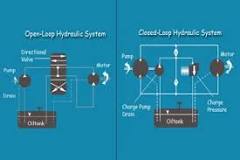

What are the two main types of hydraulic systems?

Open loop hydraulic system and closed loop hydraulic system are the two types of hydraulic system. In an open loop system, when the actuating mechanism is idle, there will be fluid flow but no pressure. For a closed loop system, when the pump operates there will be pressure for fluids.

How do you size a hydraulic pump?

If system pressure and flow are constant, motor sizing simply involves the standard equation: hp = (Q ×P) ÷ (1,714×EM ), where: hp is horsepower, Q is flow in gpm, P is pressure in psi, and EM is the pump’s mechanical efficiency.

How fast can a hydraulic motor spin?

They can spin at up to 3,000 RPM, but are less quiet than ball screws. Piston: These motors are found in things like lawn mowers and power washers. They can spin at up to 2,500 RPM, but are less accurate than ball screws or rotary vanes.

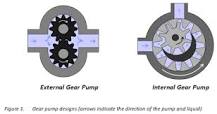

Can I use a gear pump as a motor?

External gear pumps can also be used in hydraulic power applications, typically in vehicles, lifting machinery and mobile plant equipment. Driving a gear pump in reverse, using oil pumped from elsewhere in a system (normally by a tandem pump in the engine), creates a hydraulic motor.

What is CC in hydraulic pump?

What Does cc Mean? Cc is the abbreviation for cubic centimeters and is used to measure the hydraulic fluid volume displaced per revolution (one complete Rotation).

How does a 2 speed hydraulic motor work?

A speed hydraulic pump is a type of hydraulic pump that uses two pistons to move the fluid. The pistons move the fluid through the pump by pushing and pulling on the fluid. This allows the pump to move larger quantities of fluid than single-piston pumps.

What is the difference between electric motor and hydraulic motor?

Electric motors don’t respond well to loads that can stall them. If an electric motor is stalled by a heavy load, there is a good chance that permanent damage will be done. Hydraulic motors may stall under an excessive load but will suffer no permanent damage.

How does a hydraulic pump and cylinder work?

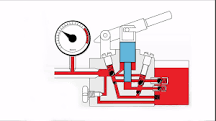

Does a hydraulic pump create flow or pressure?

A pump produces liquid movement or flow: it does not generate pressure. It produces the flow necessary for the development of pressure which is a function of resistance to fluid flow in the system.

What drives a hydraulic pump?

A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. It generates flow with enough power to overcome pressure induced by the load.