Nozzles : It is the component which breaks the fluid in to fine droplet . Automation of spray fluid is usually achieved by discharging the liquid through an orifice called nozzle under pressure. Atomization is also achieved by breaking up the jet of liquid with a blast of air.

What are the 3 kinds of spray tools? Types of Paint Sprayers Choose from the following three types: airless, pneumatic and HVLP.

What is spraying equipment? Horticultural spraying equipment is used worldwide to apply crop protection products, like pesticides. In addition, spray equipment is also used for cleaning or spraying pesticides.

What are the four basic components of spray output equipment? All sprayers have several basic components: pump, tank, agitation system, flow-control assembly, pressure gauge, and distribution system (Figure 1).

What are the five components of conventional spraying equipment?

- Low Pressure Aspersion.

- Airless.

- Airless Air Assisted.

What does HVLP stand for? You have probably already asked yourself what the abbreviation “HVLP” actually stands for. HVLP stands for “high volume low pressure“, which means a “high air volume, low pressure” .

Which component of sprayer is very important? – Related Questions

What is an HVLP sprayer?

HVLP spray guns dispense finishes at high volume, low pressure (HVLP) which results in less overspray and, when used properly, a finer finish. Cabinetmakers and furniture builders love them. There are two kinds of HVLP spray gun systems. A dedicated system employs a turbine to atomize the finish.

Which tool is used to spray chemicals?

Hydraulic sprayers range from large powered units with multiple-nozzle booms to small manual backpack or hand-held compressed-air sprayers. In all cases, pressure from either a pump or compressed gas or air is used to atomize the spray mix at the nozzle.

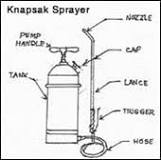

What are the parts of sprayer?

- Wand.

- Nozzle.

- Control Locks.

- Pressure-Release Valves.

- Pump Handle with Flow Control.

- Hose or Tube.

- Pump.

- Sprayer Tank.

What are spraying techniques?

In spraying, the chemicals to be applied are dissolved or suspended in water or, less commonly, in an oil-based carrier. The mixture is then applied as a fine mist to plants, animals, soils, or products to be treated.

How many types of sprayers are there?

There are three types of Knapsack sprayers i.e battery, manual and battery cum manual sprayer. Portable power sprayers are operated by electric and petrol engine with the help of hose pipe.

How many parts does a spray gun have?

A two-component spray gun is a piece of equipment used to propel two separate pressurized coatings or lining fluids (from two different spray tanks) onto a metal surface at the same time. It is directly connected to a spray head nozzle to facilitate a precise application.

What PSI is HVLP?

HVLP, or High-Volume/Low Pressure, uses a high volume of air (typically between 15-26 CFM) delivered at low pressure (10 PSI or less at the air cap) to atomize paint into a soft, low-velocity pattern of particles.

What are the different types of spray guns?

There are three basic types of paint sprayers: airless, high-volume low-pressure (HVLP), and compressed or pneumatic.

How many CFM does a HVLP gun need?

– An HVLP Spray Gun uses a lot of air and the more you have the better. However, you will typically always need at least 8 CFM for the lowest consuming air volume HVLP Spray Gun, we recommend a minimum of 30 CFM to prevent issues with the gun not atomizing well and changes in the fan pattern occurring.

Which is better LVLP or HVLP?

The FPro LVLP spray gun technology atomizes difficult coatings, higher viscosities, water borne and higher flow rates better than HVLP guns. The LVLP guns applies coatings faster making them better suited for large objects and high production applications.

What does LVLP stand for?

What does LVLP stand for? LVLP stands for low volume low pressure. They work with lower pressure at the nozzle than an HVLP (High Volume High Pressure Gun). How low?

Is airless or HVLP better?

HVLPs are more fine production, not high production.” Unlike airless spray guns, HVLP guns have a second control knob that regulates air flow, giving the user more control over the fan size. There is less overspray, making HVLPs a good choice when working with expensive paint.

What size compressor Do I need to spray paint a car?

Look for a minimum of 15 psi, with some applications, such as clear coat, better-suited to 20 or 25 psi. Horsepower: For auto painting, a 10hp compressor will typically suffice. However, higher horsepower compressors may operate more efficiently, and can be used for other tasks.

Can you paint a car with a LVLP gun?

Yes, absolutely. You can shoot both base coat, clear coat as well as metallics. I’d recommend the LVLP if you’re on a tight air compressor set up. If you want to be technical, HVLP spray guns are for good for base coat while an LVLP spray gun is recommended for clear coat.

How much CFM do I need for LVLP?

Air Pressure Setting on LVLP Spray Guns (Low Volume Low Pressure) Most people suggest you should set your gun at 10-15 PSI when spraying base coat. These guns use 5-7 SCFM (standard CFM) with the volume of air at 40 PSI.

What are spray pumps?

Spray pumps are finger-actuated mechanisms for the metered dispensing of products in spray form from non-pressurised containers.

What is mechanical sprayer?

• The sprayer is a device which converts mechanical energy. into pressure energy and the liquid in the sprayer container is. sprayed with the help of nozzle. 2 sprayers are used to. increase the efficiency of the machine.

What is power sprayer?

A power sprayer is an equipment used to apply fertilizers to plants, grass, creepers, and shrubs in agriculture and landscaping. By Using this power sprayer, you can boost crop productivity. In the field, it might be used to spray pesticides, fungicides, insecticides, and other substances.

What are the functions of sprayers?

The main function of a sprayer is to break the liquid into droplets of effective size and distribute them uniformly over the surface or space to be protected. Another function is to regulate the amount of insecticide to avoid excessive application that might prove harmful or wasteful.

What are the types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What are the classification of sprayer?

Types of sprayers Depending on the source of power it can be classified as manually operated and power operated dusters. The manually operated dusters are (i) package duster (ii) plunger duster (iii) bellow duster and (iv) rotary duster.

What is chemical spray?

[′kem·i·kəl ′sprā] (ordnance) Aerial release, or device for aerial release, of liquid war gas for casualty effect, or of liquid smoke for aerial smoke screens.

What is high volume spray?

High volume low pressure refers to a type of applicator used to spray paint on a surface to be coated for corrosion protection. High volume low pressure (HVLP) sprayers operate on the basis of vacuum creation and turbine support.

What are hydraulic sprayers?

Definition of hydraulic sprayer : a machine for the large-scale application of insecticides or fungicides to crops in the form of a spray — compare mist blower.

How many types of spray are there?

There are three types of Knapsack sprayers i.e battery, manual and battery cum manual sprayer. Portable power sprayers are operated by electric and petrol engine with the help of hose pipe.

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What are the different types of spray guns?

There are three basic types of paint sprayers: airless, high-volume low-pressure (HVLP), and compressed or pneumatic.

What are the different types of spray bottles?

There are two basic types of refillable spray bottles: I) metal bottles that spray product using compressed air and 2) plastic bottles that use a hand pump to spray product. Refillable metal bottles more closely resemble aerosol cans in terms of their design and performance.