Compressor Air Requirements Specifications for air-powered nailers detail the cubic feet per minute (CFM) and pressures (PSI) needed. Minimum pressure is at least 70 psi while 90 is a more useful target level.

How do you make an air nozzle?

How do you install a nozzle on an air compressor?

What is an air compressor safety nozzle?

What is an air nozzle? Air nozzles are used for dispersing air or steam in a concentrated and straight fan. Generally, air nozzles have a flat fan or solid stream respective round fan spray pattern. When using conventional air nozzles, air is blown through a single hole. Often a loud, ear-splitting and hissing noise is produced.

How do you increase air pressure?

What PSI should I set my air compressor for nail gun? – Related Questions

What pressure is canned air?

The maximum pressure for an aerosol can is typically 10 bar (145 psi) at 20 °C (68 °F).

What are the two types of air couplings?

Couplers come in a range of styles, including automotive, industrial, ARO and V-style. There are two main types of couplers — automatic and manual. Automatic fittings allow you to plug your air lines in directly.

How do you hook up a nail gun to an air compressor?

How do I release pressure from my air compressor?

Grip the ring on the valve with a pair of locking pliers. Turn the valve counterclockwise with the pliers. Open the valve only a little at first until the pressure lessens. Continue to open the valve more, allowing both air and condensation to release from the tank.

What is an OSHA compliant air nozzle?

Compressed air used for cleaning purposes must be regulated to keep the pressure below 30 psi, or must use a nozzle with relief holes or other safety features (e.g., star tipped nozzle) that limit the air pressure to 30 psi or less when dead-ended (i.e., when the primary nozzle opening is held against a flat surface).

At what pressure can air penetrate skin?

A pressure strong enough to dust or clean is strong enough to breach the skin and penetrate the body. Even pressures as low as 5-10 pounds per square inch (psi) can cause serious injury.

How much air pressure do you need for an air gun?

Most air tools require a working pressure of approximately 90 PSI in order to operate. This also applies to compressed air blow guns. This level of pressure can have serious or even fatal consequences for users and equipment.

What is an air nozzle used for?

An air nozzle is a device used control the direction or characteristics of air flow by converting pressure into flow. Air Nozzles are the smallest air amplifiers for point application. Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges.

What does a safety nozzle do?

Safety nozzles are designed to prevent blockages, ensuring that the pressure at the main nozzle, in most cases, remains low enough to reduce the possibility of injury. There are two types of safety nozzles; Aircurtain and Reduced jet-velocity.

Does reducing pipe size increase air pressure?

Because if the diameter of a pipe decreased, then the pressure in the pipeline will increase. As per Bernoulli’s theorem, pressure can be reduced when the area of conveyance is reduced. In the narrower pipe, the velocity can be high, and pressure can be higher.

Can you make a pressure washer with an air compressor?

Simply saying, the answer is no. A garden hose cannot operate at the same pressures necessary or regarded as standard for a pressure washer. Yet, you might be able to buy a special adapter that claims to make a pressure washer gun work with an air compressor & garden hose.

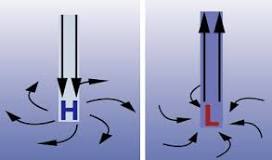

What happens when there is low air pressure?

A low pressure system has lower pressure at its center than the areas around it. Winds blow towards the low pressure, and the air rises in the atmosphere where they meet. As the air rises, the water vapor within it condenses, forming clouds and often precipitation.

Why is compressed air cold upside down?

Because these gases are compressed to liquid form, when you turn the can upside down and press the nozzle, liquid will come out before it turns to gas. A pocket of gas sits at the top of the can, preventing liquid from spraying out when the can is right side up.

What happens if you shake compressed air?

According to 3M, which manufactures and sells compressed air canisters for dust removal, shaking or tilting the can may result in propelled liquid instead of vapor. If this happens, the liquid may come into contact with skin or eyes, warns 3M, and cause frostbite because the chemical will freeze skin.

What liquid is in compressed air?

The stuff in a compressed air can isn’t actually air—at least not the air we breathe. It’s actually a chemical called difluoroethane. Difluoroethane is commonly found in refrigerators and aerosol cans, including cans of compressed air.

What is the most common air coupler type?

National Pipe Thread (NPT) connections are the most popular and likely the type you need. Line couplers with an NPT connection crew onto the hose, which has threads at the end.

Are there different size air compressor fittings?

Thread sizes are typically 1/8″, 1/4″, 3/8″, 1/2″ or 3/4″ pipe thread. A fitting that has female pipe threads (FPT) can only mate to something with male pipe threads (MPT) that are of the same pipe thread size.

What is a universal air coupler?

Universal Coupler is designed to fit the most popular styles, including industrial (IM), automotive (T), and ARO. The coupler features a female NPT fitting that allows for a direct connection to an air hose.

What size air compressor do I need for a nail gun?

In most scenarios, a portable hand-carry compressor will provide more than enough power to keep your pneumatic fastening tool up and running. Take this for instance – a small 1HP portable unit (delivering 2.0 CFM – cubic feet of air per minute) allows a large nail gun to operate at about 15 nail drives per minute.

What PSI should I use for trim?

Many carpentry and trimming jobs can be accomplished with the help of a nail gun. Bostitch makes a few models of 18-gauge brad nailers to suit your individual needs. Recommended air pressure on these models ranges from 60-120 pounds per square inch (psi).

Is it OK to leave an air compressor pressurized?

With so much air under so much pressure, can you leave an air compressor full? The short answer is yes, it is perfectly safe to leave an air compressor full. However, this assumes that it has been properly maintained, with regular draining to remove accumulated moisture from inside the tank.

Do you have to drain your air compressor after every use?

Draining your compressor after every use is not necessary unless you use it very rarely. A good practice would be to drain the compressor tank every couple of days for daily use. This helps you remove the condensate and moisture gathered inside the tank, slowing down the corrosion process.

How long can you leave an air compressor full?

Depending on the size and type of compressor, air compressors can be left running anywhere from a few hours to 24 hours a day, seven days a week.

How do you change a nozzle on an air pump?

- Remove all pressurized air from the air compressor by opening the drain valve on the bottom of the tank. …

- Wrap a new strip of Teflon tape around the end of the air hose in a clockwise direction. …

- Screw the new tire nozzle onto the tip of the air hose in a clockwise direction.

How do you hook up an air hose fitting?

How do you attach a tire inflator to an air compressor hose?

How do I know what size compressed air pipe to use?

Typically, you can multiply the capacity of straight-line piping by 1.5 for loop type compressed air distribution systems. For example: If a 2” aluminum pipe is rated for 500 CFM at 125 PSI, that same length of pipe in a loop system would be rated for 750 CFM at 125 PSI.