Running from 40-80 PSI usually. As crw said, the controller will try to match the pump to your ground speed by changing the speed of the pump. That will of course affect the pressure at the nozzles. Lower pressures should mean courser droplets, high pressure = finer droplets.

How does pressure relief valve work sprayer?

What are the three types of relief valves? The three basic types of industrial relief valves are conventional spring loaded, balanced spring loaded, and pilot operated.

How much PSI does a pump sprayer have? The hand held sprayer has a plastic compression pump that is sealed with rubber O-rings. The compression pump is hand actuated to an operating pressure of 40 PSI.

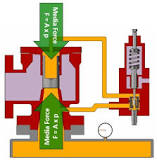

How does a pilot operated relief valve work?

Is it normal for water to come out of pressure relief valve? While it’s normal for some water to leak from the pressure relief valve, the unit itself should never leak water. This can happen when the valve doesn’t properly relieve pressure from the unit and, in response, the tank ruptures.

What pressure should a sprayer run at? – Related Questions

How do you adjust a pressure relief valve?

What is the difference between pressure safety valve and pressure relief valve?

Relief valves are designed to help your facility avoid system failures, and protect equipment from overpressurized conditions. The term safety valve, on the other hand, refers to pressure valves that are designed to protect people, property, and processes.

How do you size a pressure relief valve?

- Connection size and type. The valve size must correspond to the size of the inlet and discharge piping. …

- Set pressure (PSIG) …

- Temperature. …

- Back pressure. …

- Service. …

- Required capacity.

Where should a pressure relief valve be used?

Pressure relief valves are used across an array of applications in which pressure levels are critical for uninterrupted and smooth machinery performance. These include oil and gas, petrochemical, and power generation using steam, air, gas or liquid.

What pressure should sprayer be set at?

Depending on the type of spray tip installed, a pressure range (at the spray tip) of 10 to 30 pounds per square inch (psi) is usually appropriate for herbicides, while a range of 30 to 50 psi is most often appropriate for insec- ticides and fungicides.

How do you release pressure from a sprayer?

What is the difference between a regular relief valve and a pilot operated relief valve?

When the process pressure force on the disc overcomes the opposing spring force, the disc lifts and the valve begins to relieve pressure. In contrast, a pilot operated valve uses process pressure to keep the valve closed until set pressure is reached.

What is the difference between pilot-operated and direct operated pressure relief valve?

The main difference between direct acting and pilot solenoids is that direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves employ the use of the process fluid to assist in piloting the operation of the valve.

What are the types of pressure relief valve?

The three basic types of pressure-relief valves are conventional spring loaded, balanced spring loaded, and the pilot operated.

How often should a pressure relief valve leak?

In general, we recommend the following schedule: Testing every 12 months. Repair every three to five years.

What happens if pressure relief valve fails?

And when a PRV fails, it can lead to an explosion. Damaged equipment, disrupted work flow, and even injury may result. Why take that risk when you can easily tell whether or not your pressure relief valve needs replacing or repair.

How do I know if my pressure relief valve is bad?

- Low or Fluctuating Water Pressure. …

- No Water Pressure. …

- Hammering or Vibrating Noises. …

- A Leak in your Flower Bed. …

- High Water Pressure.

What pressure should a pressure reducing valve be set at?

Pressure reducing valves are required by code when the street pressure is higher than 80 psi.

Is 70 psi too high for water pressure?

How High Is Too High? The ideal water pressure level is between 50-70 PSI. If your water pressure goes above 70 PSI (even occasionally), you should install a pressure regulator to your main water line.

How long does a pressure reducing valve last?

How long will a Water Pressure Reducing Valve last? The life expectancy of a water pressure regulator is most commonly in the range of 10 to 15 years. However, you may see a regulator malfunction at three years and one still properly functioning at 20 years old if regularly maintained.

Does length of pressure relief valve matter?

Longer should be OK as long as it fits properly but shorter is not. If a valve has been previously replaced with one with a longer probe, then it must be safe, on the next replacement, to use a valve with a probe shorter then the one currently installed, as long as it is longer then the original one.

Is a pressure relief valve necessary?

Without the valve, your water heater may run the risk of an explosion if the temperature or pressure got higher than what the tank was designed to handle. To put it simply, storage water heaters can be hazardous or even lethal if they do not come with a temperature and pressure relief valve.

What will happen when a pressure relief valve is opened?

In systems where the outlet is connected to piping, the opening of a relief valve will give a pressure build-up in the piping system downstream of the relief valve. This often means that the relief valve will not re-seat once the set pressure is reached.

How do I adjust the pressure on my Fimco sprayer?

When you are ready to spray, turn the boom valve to the “on” position. This will start solution spraying from the tips of the boom. The pressure will decrease slightly when the boom is spraying. Adjust the pressure by turning the “ON/OFF” valve lever on the bypass line valve.

What does an electric boom valve do?

Use this electric boom shutoff valve alone or in a series to control your boom sprayer and other crop spraying systems. This solenoid valve runs off of 12 Volt DC and draws 2 amps per valve. The boom shutoff valve has a maximum operating pressure of 175 PSI and can handle a flow of 0 to 8 gallons per minute.