This spray is formulated to inhibit rust and corrosion of metal surfaces. It is suitable for use in transmission and distribution equipment including towers, transformers, light standards and other metal and galvanized surfaces.

What is arc spray system? Arc spray (sometimes referred to as twin wire arc spray) is a process that uses an electric arc to melt wires. The molten metal is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed.

What is zinc arc spray? The Process. Zinc thermal spraying is a process where zinc or zinc alloys are melted and then sprayed onto a prepared substrate, creating a layered coating. Thermal spraying is a highly effective and proven method of corrosion prevention, giving galvanic as well as barrier coating protection to iron and steel.

What is Twin arc? The Twin Wire Arc Spray (TWAS) process is an automated system for depositing a high-performance thermal coating onto parts that are subject to corrosion and erosion. This coating provides an excellent barrier layer to protect components from deterioration while enhancing their lifespan.

What is arc wire? Wire arc spraying involves two consumable metal wires. When fed into the spray gun, these wires are electrically/thermally heated to their melting points and then sprayed onto a metallic surface. This method of coating is especially suitable for providing corrosion protection to materials with low melting points.

What is metal spraying process? Metal Spraying is a process that has been used for over 100 years around the world, where molten metal or softened particles are applied to a prepared surface (substrate) to enhance its properties (hardness, anti-corrosion, wear, dielectric, restoring dimensions etc.).

What is zinc spray used for? – Related Questions

How does thermal spray work?

The Basics of Thermal Spraying Combined thermal and kinetic energy causes the particles to flatten or ‘splat’ onto the surface, and onto each other, to produce a cohesive coating of successive layers. Metallurgically cold process.

What is hot zinc spray?

This is a process where Zinc Wire is melted through a gas pistol and sprayed onto the metal surface which will galvanise the metal in the same was as Hot Dipped Galvanising. We can also spray aluminium, bronze, copper and stainless steel in the same way.

What is Thermal Spray galvanizing?

A zinc thermal spray is a way to apply a zinc coating to a substrate material. A zinc thermal spray uses the thermal spraying process to adhere the zinc to the base material, as opposed to hot dip galvanizing, electrogalvanizing or other methods of galvanizing.

Why DC supply is used in carbon arc welding?

It is because, if the carbon electrode is made positive, the carbon particles have a tendency to go into the welded joint and make it brittle. Therefore, the electrode in carbon arc welding is always kept negative and the work positive. For carbon arc welding, only DC supply can be used.

Why is carbon used in carbon arc welding?

Why is carbon used in carbon arc welding? Explanation: Carbon is used in carbon arc welding, at the negative terminal of the cathode. The reason for employing carbon at the negative terminal is that, a lesser amount of heat is generated at the electron tip than at the workpiece.

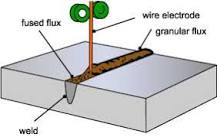

What is saw welding process?

Submerged-arc welding (SAW) is a common arc welding process that involves the formation of an arc between a continuously fed electrode and the workpiece. A blanket of powdered flux generates a protective gas shield and a slag (and may also be used to add alloying elements to the weld pool) which protects the weld zone.

What is plasma spray coating?

Plasma spray is a thermal spray coating process used to produce a high quality coating by a combination of high temperature, high energy heat source, a relatively inert spraying medium, usually argon, and high particle velocities.

What are the two main methods of metal spraying?

Both flame spraying and arc spraying techniques are used to add these protective coatings.

Which metal is used for metal spraying?

A zinc-aluminium alloy is sprayed on as corrosion protection. Molybdenum, bronze, nickel, NiCrBSi, chrome-nickel-iron alloys and Wolfram/ Tungstencarbide hard metal are used as wear protection in surface coating.

What is hot metal spraying?

Thermal metal spraying is a term used to describe a technique in which melted (or heated) metallic materials are sprayed onto a surface. The metallic material can be heated either electrically (plasma or arc) or by chemical means (combustion flame).

What are the types of thermal spraying?

- HVOF (High Velocity Oxy-Fuel Spraying) HVOF is a process which makes use of a torch that allows the flame to spread whenever the nozzle is used. …

- Combustion Flame Spraying. …

- Plasma Spraying. …

- Vacuum Plasma Spraying. …

- Two-Wire Electric Arc Spraying.

What materials can be thermal sprayed?

Thermal Spray is a range of high-performance ceramic, cermet and metallic coatings that can be applied to a range of steel, titanium, aluminium, and copper alloys, as well as to some non-metallic substrates.

Where is thermal spraying used?

Thermal spray coatings are extensively used in the manufacturing of gas turbines, diesel engines, bearings, journals, pumps, compressors and oil field equipment, as well as coating medical implants.

Does zinc spray stop rust?

About Cold Galvanizing Compound Spray Instantly galvanize metal surfaces to protect them from corrosion with Rust-Oleum® Stops Rust® Cold Galvanizing Compound Spray. This 93% pure zinc coating applies a galvanized film with cathodic protection, which resists rusts, scratches and chips.

Does zinc stop rust?

Zinc is more reactive than iron and steel, so it oxidizes (loses electrons during a chemical reaction) instead of the iron or steel. Typically when iron and steel oxidize, they rust. So zinc acts as a “sacrificial metal” to prevent the iron and steel from rusting.

When should I use zinc spray?

- Windmill towers.

- Chemical, cement and fertilizer industries.

- Refineries.

- Power plants.

- Pipelines.

- Bridges and other marine applications.

- Transformer tanks.

- Radiators.

What is the difference between metalizing and galvanizing?

Metalizing an industrial part begins with abrasive cleaning. Then, melted zinc powder or wire is applied onto the part through compressed air or combustible gases. Unlike hot-dip galvanizing, where the metal’s temperature increases while dipped in molten zinc, the metal’s temperature stays the same during metalizing.

Can zinc be sprayed?

Zinc spraying, or metallizing, is accomplished by feeding zinc in either wire or powder form into a heated gun, where it is melted and sprayed onto the part using combustion gases and/or auxiliary compressed air to provide the necessary velocity.

What causes wires to arc?

Arcing usually occurs when a circuit becomes overloaded and overheats. The overheating causes damage not only to the circuit breaker but also to its connection to the bus. Once damaged, a circuit breaker can malfunction and continue to let electricity flow between its connection instead of tripping.

What causes an outlet to arc?

When electricity runs through a wire (copper or aluminum), the wire expand due to the flowing electricity creating heat and when off, the wire contracts. This continual expansion and contraction over the year’s results in wiring connections becoming a little loose; these loose connections may result in arcing.

Why do powerlines arc?

There are three ways power lines can contact each other or the ground and cause a short circuit and resulting arc: Damage or collapse of the wires’ support system (telephone poles, insulators or crossarms) due to external force (wind, ice).

What does an electrical arc sound like?

At times electrical switches tend to make sizzling/popping/crackling sounds whenever they are switched on and off- this is referred to as arcing and it can be of two types.