Turbo nozzles are designed to optimize and maximize the pressure you can get out of your pressure washer, all the while cleaning surfaces faster without exerting more effort.

Which type of nozzle is used for insecticide spray? Hollow-cone nozzles (Figure 2F) generally are used to apply insecticides or fungicides to field crops when foliage penetration and complete coverage of the leaf surface is required. These nozzles operate in a pressure range from 40 to 100 psi.

What are the different types of spray nozzles? There are 5 basic spray pattern types: flat fan, solid stream, full cone, hollow cone and mist/fog.

Which nozzle is best for herbicide spray? Extended Range Flat Fan Nozzle Any pressure above 30-40 PSI will produce a fine droplet that is more likely to drift. Extended range flat fan nozzles are most often used for spraying contact products such as: Herbicides. Insecticides.

How do I choose a nozzle? Selecting Your Nozzle Size You’ll want to determine the nozzle flow rate at gallons per minute (gpm). To find that, start with your application rate in gallons per acre (gpa). Next, find an efficient and safe ground speed in miles per hour (mph). Then, determine the spray width per nozzle (W).

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What is turbo nozzle? – Related Questions

How do I choose a nozzle size?

The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

What do nozzle numbers mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

What are different types of sprayers?

- Knapsack Sprayer.

- Portable Power Sprayer.

- Knapsack Power Sprayer.

- Mist Dust Sprayer.

- HTP Sprayers.

- Orchard Sprayers.

How do you read a nozzle chart?

On a standard nozzle chart, the top column that runs left to right is the pressure that you want to obtain. The left column top to bottom is the nozzle orifice size designation. The top to bottom column next to the orifice size column indicates the actual orifice measurement.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

How do Boomless spray nozzles work?

A boomless sprayer generally has one or two nozzles that can be pointed out sideways or tilted slightly up and spray out further achieve coverage. A boom sprayer typically has multiple spray tips spread out along both boom arms with even spacing and are pointed straight down towards the target.

What nozzle type is recommended when spray drift is a concern?

With medium to coarse spray, spray drift can be reduced by 50% compared to an extended range nozzle at equal flow rates. Turbo-TeeJet nozzles are an excellent choice for drift reduction compared to extended range flat fan. But these nozzles are difficult to clean, so carry a few extra when spraying.

What should be the droplet size of a spray to target flying insects?

The large number of droplets greatly increases the chances of contact being made with a flying insect as the density per unit volume of air will be so much greater (see Table 2). The optimum droplet size for space spraying against mosquitoes is 10–20 µm, for larger flies, e.g. tsetse flies, the optimum is 30 µm.

What is nozzle size?

Usually nozzle size ranges from 0.1mm to 1mm and you can choose from various options depending on your requirements. 0.4mm is considered the standard nozzle size of a 3D printer and almost all manufacturers include a nozzle of this size in their printers.

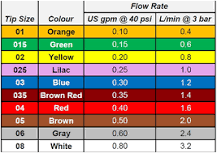

What do teejet nozzle numbers mean?

These numbers refer to the flow rate in US gallons at the rated pressure of 40 PSI (approx. 3 BAR). For example, an 02 Nozzle is rated at 0.2 US gallons per hour at a pressure of 40 PSI.

What is nozzle and its types?

A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them.

What is nozzle spray?

Spray nozzles are attachments for spraying equipment used to atomise crop protection products. A nozzle converts a jet of liquid into droplets so that a crop protection product can be evenly distributed over a crop.

What is a cone nozzle used for?

Solid cone nozzles are suitable for application of residual herbicides and systemic insecticides using a knapsack or boom mounted or for spot applications of herbicides. They produce a full cone spray pattern with coarse droplets at a pressure of 1 – 10 bar.

Which type of nozzle is most commonly used for herbicide application?

The Cone-Jet (Spray Systems) and WRW-Whirl Rain (Delavan) are wide-angle (80-120 degrees), hollow-cone nozzles. These nozzles are used for postemergence contact herbicides where a finely atomized spray is used for complete coverage of plants or weeds.

How do you calculate flow rate of a nozzle?

- Any nozzle will produce certain flow rate at a given pressure differential. …

- The flow rate for a given nozzle can be calculate by the following formula.

- Q= Flow rate.

- K = K factor for nozzle.

- P = Pressure differential at the nozzle.

- n = Is a constant that depends upon the spray pattern type.

What do colors of spray nozzles mean?

The color of the nozzle identifies the angle of the spray fan pattern measured in degrees and is generally the same across all sizes. Red is 0, Yellow 15, Green 25, and White 40. The black nozzle is used for applying soap at low pressure and is sometimes used for low pressure rinsing.

What do the colors on spray tips mean?

The first color scheme, the color of the spray nozzle tip, describes the capacity (flow rate) of the nozzle orifice at 40 PSI and is based on Standard 10625 of the International Standards Organization (ISO) (Table 1). Nozzle flow rates are mainly a function of orifice size & pressure.

What is a 515 spray tip used for?

10 inch spray pattern ideal for larger surfaces such as houses/buildings, walls and ceilings. The . 015 inch hole size is best choice for spraying interior/exterior paints, primers and enamels.

What are the two types of sprayer?

Two general types of sprayers are available for greenhouse application of pesticides: hydraulic and low-volume. There are many variations of these that fit particular crops or growing methods. In the hydraulic sprayer, a pump supplies energy that carries spray material to the target (plant foliage).

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What is pesticide sprayer?

Sprayers convert a pesticide formulation, often containing a mixture of water (or another liquid chemical carrier, such as fertilizer) and chemical, into droplets, which can be large rain-type drops or tiny almost-invisible particles.

How is nozzle pressure measured?

The nozzle pressure can be measured with a gauge placed on a nozzle body. Simply purchase a quality gauge and a threaded nozzle cap, combine the two and install in place of a nozzle. A pressure gauge threaded into a nozzle cap can measure boom pressure.

What is Meg nozzle?

1/4″ MEG Spray Nozzles connect to JRODS, surface cleaners, and other nozzle holders to provide your spray pattern and desired pressure. You can use our handy nozzle calculator below to determine what size nozzle you need.

What is a cone nozzle used for?

Solid cone nozzles are suitable for application of residual herbicides and systemic insecticides using a knapsack or boom mounted or for spot applications of herbicides. They produce a full cone spray pattern with coarse droplets at a pressure of 1 – 10 bar.

What is a drop nozzle?

Cone Tips | Nozzle Assemblies | Drop Nozzles. Like band spraying, Drop Nozzles can be used to apply pesticide directly in a band either over the row, at the base of the plant from between the row, or both. Unlike band spraying, thought, these drops are usually used for post emergent spraying.

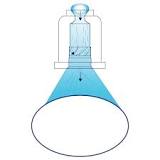

What is hollow cone nozzle?

Hollow Cone Spray Nozzles A hollow cone nozzle sprays fluids in a ring-like pattern around a given radius. Hollow cone nozzles produce a good interface between air and the surface of the droplets. There are 2 types of hollow cone nozzle designs.