knapsack sprayer work requires the operator to constantly move the left upper limb (arm) when it activates the tank pressure lever, moving the upper right limb, directing the nozzle by means of the boom sprayer and a constant walk with the sprayer being carried on his back.

How do you refill a knapsack sprayer?

How do you use a knapsack sprayer?

- Fill the knapsack sprayer with water (for instance 10-L).

- Add herbicide (say, 50 or 100 ml).

- Cover the sprayer and shake vigorously.

- Fill the sprayer with more water (eg 5-L more) until it is full.

- Spray the weeds with your herbicide solution.

What is a snap sack sprayer? Definition of knapsack sprayer : a spraying apparatus consisting of a knapsack tank together with pressurizing device, line, and sprayer nozzle, used chiefly in fire control and in spraying fungicides or insecticides.

How do you fill a 5l pressure sprayer?

What is the working principle of knapsack sprayer? – Related Questions

How many liters of liquid is the capacity of a knapsack sprayer?

Knapsack sprayer consists of a pump and an air chamber permanently installed in a 9 to 22.5 liters tank.

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What are the three classifications of sprayers?

Based up on the volume of liquid handled ,sprayers may be classified in to (1) High volume sprayer (more than 400 litres /ha) (2) Low volume sprayer (5 to 400 litres/ hectare) (3) Ultra low volume sprayer (ULV) spray (less than 5 litres /ha).

What is spray volume?

The correct volume of spray is the sprayer application rate multiplied by the number of acres. Example. You want to spray a 12-acre field and your sprayer applies 20 gallons per acre. Gallons of spray mixture = application rate (gallons per acre) × area to spray (acres) Therefore, put (20 × 12 =)

What are the disadvantages of sprayer?

Disadvantages :1. Low efficiency and large labor intensity are not suitable for large-scale operation. 2. The liquid has run, run, run, leak and drip phenomenon.

When can you start spraying for weeds?

The best time to treat weeds is when they are actively growing. This means you should start spraying and treating in the spring, usually sometime in April. You’ll have to maintain your weed-killing regiment into late September/early October. It’s best not to jump the gun when using weed killers.

How do you calibrate a knapsack sprayer?

Measure the output of the sprayer – When the knapsack is up to pressure, release the trigger and hold the nozzle right into a metric calibrated vessel like a jug and time for 1 minute, only pumping and reciting the ‘one thousand’ over and over again, making sure that you hand pump once only per ‘one thousand’ bit.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

What is a boom sprayer?

A boom sprayer is the most common type of apparatus for applying herbicides in broadscale farming. A sprayer has many components, the most important being the nozzles, which split the herbicide into many small droplets that are projected through the air to the target.

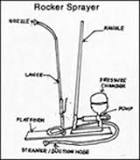

What is Rocker sprayer?

Rocker sprayer The rocking sprayer has a pump assembly, fixed on a wooden platform with an operating lever, a valve assembly with two ball valves, a pressure chamber, suction hose with strainer, and delivery hose with spray lance.

How much pressure should a pump sprayer have?

Pumping the handle or lever of your sprayer builds the pressure inside the sprayer tank. This pressure pushes the liquid out of the sprayer gun when the trigger is pulled. Most hand pump sprayers are limited to about 40 psi.

How do I fill my garden sprayer with water?

How do you install a pressure sprayer?

What is the capacity of high volume sprayer?

HV : High Volume = More than 150 l/ha. Suitable for insecticides, fungicides, herbicides.

What is ultra low volume sprayer?

ULV sprayers dispense very fine aerosol droplets that stay aloft and kill flying mosquitoes on contact. ULV applications involve small quantities of active ingredient in relation to the size of the area treated, typically less than 3 ounces per acre, which minimizes exposure and risks to people and the environment.

How do you calibrate a spray boom?

Which of the sprayer is mostly used by farmer?

Tractor-mounted sprayers are the most used, easy controls and well-engineered nozzles arrangements that carry out accurate Spraying of chemicals on the crops.

What are the types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What is the HP power required for power sprayer?

POWER SPRAYER It can be powered by a 3 HP engine or electric motor .

What are the two types of sprayer?

Two general types of sprayers are available for greenhouse application of pesticides: hydraulic and low-volume. There are many variations of these that fit particular crops or growing methods.

What is difference between sprayer and duster?

Sprayers are used to manage pests by using natural materials such as contaminations and small creatures in sprayers. A duster insecticide is a helpful tool for getting pesticides deep into cracks, crannies, and other similar spaces to kill crawling and flying insects, such as scorpions, bees, and other pests.

What are different types of manual operated sprayers?

Manually operated hydraulic sprayers viz. Knapsack sprayers, twin knapsack sprayers, foot sprayers, hand compression sprayers; air carrier sprayers such as motorized knapsack mist blower cum duster (LV) and centrifugal rotary disc type sprayers are specially suitable for spray applications in crops.

How do I calculate my sprayer output?

Simply incorporate the output of a single nozzle in gallons per minute (GPM) and multiply by 5,940. Then divide by the product of miles per hour (MPH) times the distance between nozzles in inches (width) on the spray boom.

How do you mix chemicals in a sprayer?

How do you mix a high yield 2,4-D?

According to the Hi-Yield 2, 4-D Selective Weed Killer product label, in pastures and range land: Use 1 gallon in 15 gallons of water; or small areas, use 3 to 4 fluid ounces (6 to 8 Tablespoons) per 1,000 square feet; mix 1 to 3 gallons of water and apply uniformly over the area.

How do you disassemble a knapsack sprayer?

What are the parts of a knapsack sprayer?

It consists of a piston type pump, a platform with fork, a lever to operate the pump, pressure chamber, suction hose with strainer, delivery hose, and a spray gun with flow control knob and nozzle.

What are the parts of sprayer?

- Wand.

- Nozzle.

- Control Locks.

- Pressure-Release Valves.

- Pump Handle with Flow Control.

- Hose or Tube.

- Pump.

- Sprayer Tank.

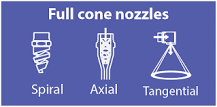

What are the different types of nozzles used in sprayers?

- Flat fan nozzles.

- Full cone nozzles.

- Hollow cone nozzles.

- Solid stream nozzles.

- Air atomising nozzles.

- Special purpose nozzles.