The most common spray angles are 65 degrees, 80 degrees, and 110 degrees. Recommended nozzle heights for flat-fan nozzles during broadcast application are given in Table 1.

Where do you put blue lights on a sprayer? For best results the lights should be mounted on the wing booms close to the pivot shining out to the end of the boom. They need to be behind the nozzles so that the light will illuminate the nozzle pattern.

How high should a sprayer boom be off the ground? This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

What is a sprayer boom? Definition of spray boom : a pipe with attached nozzles for distributing spray from a tank.

Is led a light? LEDs are “directional” light sources, which means they emit light in a specific direction, unlike incandescent and CFL, which emit light and heat in all directions. That means LEDs are able to use light and energy more efficiently in a multitude of applications.

Where should I mount my sprayer boom lights? For best results the lights should be mounted on the wing booms as close to the pivot as possible. They need to be behind the boom so that the light will illuminate the nozzle pattern. No special mounting brackets are required. Once the lights are mounted, connect them to the field lights.

What is the standard nozzle spray angle? – Related Questions

Where are Tiger lights made?

Owned by Randy Raschein and, Dana Mikkelsen, Tiger Lights was founded in 2013 and operates out of a single warehouse in Tangent, Oregon, specializing in LED lighting for agricultural and industrial equipment.

Which nozzle is best for herbicide spray?

Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

How do you choose nozzles?

Selecting Your Nozzle Size You’ll want to determine the nozzle flow rate at gallons per minute (gpm). To find that, start with your application rate in gallons per acre (gpa). Next, find an efficient and safe ground speed in miles per hour (mph). Then, determine the spray width per nozzle (W).

Why is it called a boom sprayer?

What is Boom Spraying? A Boom Sprayer usually has multiple spray nozzles (tips are usually the American terminology) spread out along arms (booms), pointed directly down.

What are the disadvantages of sprayer?

Disadvantages :1. Low efficiency and large labor intensity are not suitable for large-scale operation. 2. The liquid has run, run, run, leak and drip phenomenon.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

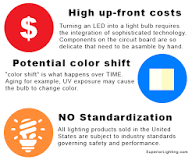

What are the disadvantages of LED?

- High up-front costs.

- Transformer compatibility.

- Potential color shift over lamp life.

- Performance standardization has not yet been streamlined.

- Overheating can cause reduced lamp life.

What color LED uses the least power?

LED voltage Red LEDs have the lowest voltage, yellow and green are a little higher. Blue and white LEDs have the highest voltages.

Do LED lights burn out?

Unlike incandescent light bulbs, LEDs don’t produce light using heat. This is part of what makes them so energy efficient. The downside is that their components can be sensitive to overheating, which can cause them to burn out prematurely.

What is a Tiger light?

Tiger Lights specializes in LED lights for Agricultural and Industrial equipment. Industrial. High levels of performance and ability to illuminate large spaces easily.

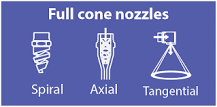

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

Which nozzle is most commonly used for herbicide application?

Flat-fan nozzles are widely used for broadcast spraying of herbicides. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2A).

What are the 2 types of nozzles?

The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

How many nozzles does a boom sprayer have?

Five nozzles can produce the required flow, each at different pressures.

What is a wet boom?

A wet boom has a rigid pipe usually stainless, with holes in it for the fittings spaced every 15-30 inches. A dry boom is fittings with flexible hoses connecting to each fitting.

How do I know what size spray nozzle to buy?

- Use smaller tip size when applying thinner materials such as stains and enamels.

- Use larger sizes for thicker materials such as exterior, latex and oil based paints.

- The larger the size of the tip hole, the faster the material leaves the gun. A 313 tip sprays faster than a 311 or 411 tip.

How do you calculate nozzle size?

To find the correct nozzle size you need to know the flow of your system and the pressure you wish to achieve. First, select the column with the required pressure across the top, then read down the column to find the amount of flow of your system.

What are the different types of nozzles used in sprayers?

- Flat fan nozzles.

- Full cone nozzles.

- Hollow cone nozzles.

- Solid stream nozzles.

- Air atomising nozzles.

- Special purpose nozzles.

What is the function of sprayer?

The main function of a sprayer is to break the liquid into droplets of effective size and distribute them uniformly over the surface or space to be protected.

What are the components of a boom sprayer?

- Hose Drops & Hose Swivels. 19 items.

- Nozzle Bodies. 300 items.

- Nozzle Body Boom Clamps. 23 items.

- Tip Screens & Tip Check Valves. 55 items.

How is boom spray calculated?

To calculate spray application rate (L/ha) For general broadcast spraying, the swath width is equal to the number of nozzles multiplied by the nozzle spacing. For band spraying the swath width is equal to the total of all the band widths.

What are the parts of sprayer?

- Wand.

- Nozzle.

- Control Locks.

- Pressure-Release Valves.

- Pump Handle with Flow Control.

- Hose or Tube.

- Pump.

- Sprayer Tank.