The big difference is the particle size of the powder that can be sprayed. Cold spray can spray much finer particles, including nanocrystalline powders. Cold spray powders typically have a grain size of 1-50 µm whereas thermal spray powders vary from 10-100 µm depending on the specific thermal spray process.

What is the difference between HVOF and HVAF? HVOF vs. The combustion temperature in an HVAF gun is typically 1,000°C (1,830°F) lower than that in an HVOF coating system. This lower temperature is ideal for the gradual heating of the feedstock particles of metals and cemented carbides to or slightly above the metal’s melting temperature.

What is HVOF thermal spray? High Velocity Oxygen Fuel (HVOF) coating is a thermal spray process in which a fuel and oxygen are mixed, fed into a combustion chamber, and ignited. The gas produced in the combustion chamber has an extremely high temperature and pressure and is ejected through a nozzle at supersonic speeds.

How do you remove HVOF coating? Whilst HVOF process gives excellent coating due to the very high adhesion and dense structure it is very difficult to remove. The current methods to remove HVOF coating are chemical stripping or mechanical grinding.

What is HVOF tungsten carbide coating? HVOF tungsten carbide coating is an industrial coating process that uses combustive thermal spray at high velocity to develop exceptional wear and corrosion resistance. The process is commonly referred to as High-Velocity Oxygen Fuel spraying (HVOF).

What is HVAF coating? HVAF or High Velocity Air-Fuel is a thermal spray process for deposition of coatings for protection of parts, vessels and structures against abrasion, erosion and corrosion. Common uses: abrasion protection. erosion protection.

What is the difference between cold and thermal spray? – Related Questions

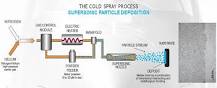

What is cold spray technology?

Cold spray is an emerging spray coating technology during which process spray particles take place through intensive plastic deformation upon impact in a solid state at temperatures well below their melting points. Therefore, spray particles experience little oxidation or decomposition during this process.

What does Hvof stand for?

High Velocity Oxygen Fuel (HVOF) coating is a thermal spray coating process, which is used to improve or restore a component’s surface (properties or geometry). This surface engineering technique better enables life extension of equipment by increasing erosion and wear resistance, and corrosion protection.

How does thermal spray work?

The Basics of Thermal Spraying Combined thermal and kinetic energy causes the particles to flatten or ‘splat’ onto the surface, and onto each other, to produce a cohesive coating of successive layers. Metallurgically cold process.

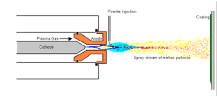

What is plasma spray coating?

Plasma spray is a thermal spray coating process used to produce a high quality coating by a combination of high temperature, high energy heat source, a relatively inert spraying medium, usually argon, and high particle velocities.

What is TCC coating?

Tungsten carbide is a common coating material used in various industries. Take a closer look at what these coatings are and what it is used for, along with its properties that help it stand out, such as resistance to erosion, corrosion, and abrasion.

Why is tungsten carbide used for coating?

Tungsten Carbide (WC) is an extremely hard ceramic material in the form of grey fine powder particles. This material exhibits excellent wear, abrasion and scratch resistance due to its high hardness. It shields the surface from damage and other surface-based attacks like corrosion, erosion, and fatigue.

How is tungsten carbide coating done?

Tungsten carbide coatings are achieved through the HVOF thermal spray process. Within this process, fuel gas and oxygen are combusted in a high-pressure chamber reaching temperatures up to 5,600°F (3,093°C).

Which gas is used in cold spray?

Cold spray uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic de Laval nozzle above a critical velocity for particle adhesion.

What is cold spray made of?

Liquified petroleum gas including propane and butane is sometimes used. These all may also be used as a topical anesthetic, due to the numbing effect of cold, though there is risk of frostbite.

What is metal spray coating?

What Does Metal Spray Coating Mean? Thermal spraying is a group of coating processes in which finely divided metallic or nonmetallic materials are deposited in a molten or semi-molten state to form a coating. The coating material may be a powder, ceramic rod, wire or molten material.

How hot is HVOF?

By injecting room temperature inert gas into the combustion gas jet of HVOF, the temperature of the propellant gas can be controlled in a range approximately from 2300 to 1000 K so that many powder materials can be deposited in thermally softened state at high impact velocity.

What are the types of thermal spraying?

- HVOF (High Velocity Oxy-Fuel Spraying) HVOF is a process which makes use of a torch that allows the flame to spread whenever the nozzle is used. …

- Combustion Flame Spraying. …

- Plasma Spraying. …

- Vacuum Plasma Spraying. …

- Two-Wire Electric Arc Spraying.

What is thermal spray material?

Thermal spray is a process where metals, ceramic, cermet and selected polymeric materials are fed in the form of powder, wire and rods to a torch where the materials are heated or melted, and accelerated in the gas stream towards a substrate where they form a splat.

What is plasma coating made of?

The plasma gases commonly used are argon, hydrogen, helium, nitrogen, or mixtures thereof. By controlling the plasma gas composition, its thermal conductivity and viscosity can be adjusted. The plasma jet heats the spray material which may be injected into the plasma jet inside or outside the nozzle.

How does plasma spray work?

The Plasma Spray Process is basically the spraying of molten or heat softened material onto a surface to provide a coating. Material in the form of powder is injected into a very high temperature plasma flame, where it is rapidly heated and accelerated to a high velocity.

How thick can you spray weld?

The limitations of spray-arc welding are: It is only used for material 1/8 inch (3mm) thick and thicker (handheld) and. It is limited to flat and horizontal fillet weld positions. Good fit-up is always required as there is no open root capability.

How is tungsten carbide coating applied?

Tungsten Carbide Coatings Applied typically through HVOF spray technology, tungsten carbide is comprised typically of powdered tungsten and cobalt, and it has nearly twice the strength of steel. Tungsten carbide provides exceptional protection for tools and machinery subject to high abrasive wear environments.

What are the types of thermal spraying?

- HVOF (High Velocity Oxy-Fuel Spraying) HVOF is a process which makes use of a torch that allows the flame to spread whenever the nozzle is used. …

- Combustion Flame Spraying. …

- Plasma Spraying. …

- Vacuum Plasma Spraying. …

- Two-Wire Electric Arc Spraying.