The word ‘spraying’ generally refers to coating processes that use a spray of particles or droplets to deposit a material onto a substrate.

What is thermal spray equipment? Thermal Spray is an industrial coating process that consists of a heat source and a coating material in a powder or wire form which is melted into micro particles and sprayed onto metal or sometimes plastic surfaces.

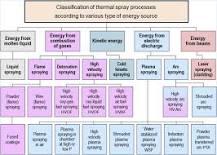

What are the types of thermal spraying?

- HVOF (High Velocity Oxy-Fuel Spraying) HVOF is a process which makes use of a torch that allows the flame to spread whenever the nozzle is used. …

- Combustion Flame Spraying. …

- Plasma Spraying. …

- Vacuum Plasma Spraying. …

- Two-Wire Electric Arc Spraying.

Where is thermal spray used? Thermal spray coatings are extensively used in the manufacturing of gas turbines, diesel engines, bearings, journals, pumps, compressors and oil field equipment, as well as coating medical implants.

How is thermal spray applied? Thermal spray coating is an industrialized process that combines a heat source with a wire or powder coating material. The material is then melted into droplets and sprayed onto a surface at a high velocity.

What is thermal spray welding? Spray welding is a term used to classify several welding procedures in the form of thermal spraying. It is an industrial activity that involves atomizing and spraying a powder or wire onto a metal surface at a high velocity with compressed gas.

What is spraying process? – Related Questions

What is a thermal spray gun?

Thermal Spray Guns The spray material is fed continuously into a fuel gas oxygen flame where it is typically dissolved by the heat of combustion. The carrier gas transports the particles into the combustion flame, and the different gases transport the material towards the treated workpiece surface.

Which is a spray material?

With cermet spray materials, consisting of hard ceramic particles and metallic binder, effort is generally made to retain the hard phase in the powder to deposit so that the compositions and microstructure of the composite deposit can be designed through powder design. WC–Co is a typical material of this kind.

What is cold spray technology?

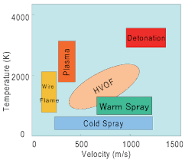

Cold spray is an emerging spray coating technology during which process spray particles take place through intensive plastic deformation upon impact in a solid state at temperatures well below their melting points. Therefore, spray particles experience little oxidation or decomposition during this process.

What is thermal coating process?

What is Thermal Spray Coating? Thermal spraying is an industrial coating process that consists of a heat source (flame or other) and a coating material in a powder or wire form which is literally melted into tiny droplets and sprayed onto surfaces at high velocity.

What forms can thermal sprayed materials take?

- Liquid.

- Ceramic rods.

- Composite or metal wire.

- Ceramic, composite, metal, or plastic powder.

What are the main steps of thermal coating process?

Thermal spray coatings are formed by successive impact of a stream of spray droplets in fully molten or partially melted states, followed by flattening, rapid cooling and solidification. Heating and accelerating of the spray materials are necessary to create spray droplets.

What is spray metal coating?

What Does Metal Spray Coating Mean? Thermal spraying is a group of coating processes in which finely divided metallic or nonmetallic materials are deposited in a molten or semi-molten state to form a coating. The coating material may be a powder, ceramic rod, wire or molten material.

Why is thermal spraying important?

Thermal spraying is a technology which improves or restores the surface of a solid material. The process can be used to apply coatings to a wide range of materials and components, to provide resistance to: Wear, erosion, cavitation, corrosion, abrasion or heat.

What is spray welding used for?

Spray arc welding is one of the processes used to transfer metal from the electrode or wire to the weld. Minute molten droplets of metal travel via the arc and on to the base metal or the joint being worked on. Spray Transfer is ideal for use on thicker metals for butt or fillet joints.

What is thermal spray Aluminum?

Thermal Sprayed Aluminum (TSA) Corrosion Protection. System for the Offshore Oil and Gas Industry. Praxair’s Thermal Sprayed Aluminum (TSA) Corrosion Protection System is an extremely durable system that provides total corrosion protection and significant life improvement over conventional barrier coatings.

What is metal spraying process?

Metal Spraying is a process that has been used for over 100 years around the world, where molten metal or softened particles are applied to a prepared surface (substrate) to enhance its properties (hardness, anti-corrosion, wear, dielectric, restoring dimensions etc.).

Which thermal spraying process creates the strongest bond?

The High Velocity Oxygen Fuel (HVOF) thermal spray system produces coating with the strongest bond and highest hardness compared to any other thermal spray process.

What is the difference between cold and thermal spray?

The big difference is the particle size of the powder that can be sprayed. Cold spray can spray much finer particles, including nanocrystalline powders. Cold spray powders typically have a grain size of 1-50 µm whereas thermal spray powders vary from 10-100 µm depending on the specific thermal spray process.

What is the temperature of cold spray?

The distinguishing feature of the cold spray process compared with conventional thermal spray processes is its ability to produce deposits with preheated gas temperatures in the range of 0 to 800° C, a range that is generally lower than the melting temperature of the coating particle materials.

What materials can be cold sprayed?

Metals, polymers, ceramics, composite materials and nanocrystalline powders can be deposited using cold spraying. The kinetic energy of the particles, supplied by the expansion of the gas, is converted to plastic deformation energy during bonding.

What is Thermal Spray for hair?

Thermal sprays do the same thing for your hair. They form a protective barrier over your hair’s cuticle, protecting it from the heat of your hair tools. And just like sunscreen, it also wards off damage caused by UV rays, which can help fight against fade, so your hair color stays fresher longer.

What is spray welding used for?

Spray arc welding is one of the processes used to transfer metal from the electrode or wire to the weld. Minute molten droplets of metal travel via the arc and on to the base metal or the joint being worked on. Spray Transfer is ideal for use on thicker metals for butt or fillet joints.