Spray drying is a drying technique used in the pharmaceutical industry to produce dry or coarse powder from liquid or slurry. It is usually used in the production of active pharmaceutical ingredients (APIs), the active ingredients in drugs.

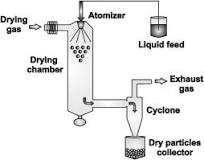

What is spray dryer how it works? A spray dryer takes a liquid stream and separates the solute or suspension as a solid and the solvent into a vapor. The solid is usually collected in a drum or cyclone. The liquid input stream is sprayed through a nozzle into a hot vapor stream and vaporized. Solids form as moisture quickly leaves the droplets.

How can I increase the efficiency of my spray dryer? Spray drying energy efficiency can be improved by widening the gap between inlet and outlet temperatures and adding heat recovery equipment. For many years, spray drying has been one of the most energy-consuming drying processes, yet it remains one that is essential to the production of dairy and food product powders.

What are the advantages of spray dryer? Benefits of Spray-Drying Some of the advantages of spray-drying include its ability to be fully automated and continuous. Short residence times and suitability for both heat-sensitive and heat-resistant foods are other advantages. The technology is suitable for a variety of feed materials, provided they are pumpable.

How do you control particle size in a spray dryer? By operating the spray dryer at very low inlet temperatures and/or low outlet humidity, we can increase the number of hollow particles from 32% to 59% for a 75:25 (WP:MD) powder, simultaneously reducing the number of wrinkled particles from 34% to 19%.

How many types of spray dryers are there? … Among them are the rotary, nozzle, two-fluid, pressure and ultrasonic nozzle (Walzel, 2011). Atomization is a crucial part of the spray dryer because it influences the drying rate, particle diameter, particle distribution, and dispersibility of the powder for rehydration (Chegini & Taheri, 2013) .

What is spray-drying in pharmaceutical industry? – Related Questions

What temperature is spray drying?

The typical spray drying process used today employs air heated up to 400° Fahrenheit to dry an atomized liquid into a powder.

What is thermal efficiency in spray drying?

It was reported that the heat efficiency of spray dryer is about 25% to 60%, and some even are below 20%[1]. The above results show that the heat consumption of spray drying is a large cost, generally speaking, the heat consumption accounts for 60% of the total cost.

What may be the factors affecting spray drying?

Scope and approach: Product yield and physical properties of the final powder are affected by various factors, including carrier material and its concentration added into the feed, feed flow rate, atomization speed/pressure, and drying temperature.

How do you run a spray dryer?

Who invented spray dryer?

Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [1, 2, 3]. Ever since it was first discovered, the spray-drying technique has been improved concerning its operational design and applications.

What is the difference between spray drying and freeze drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

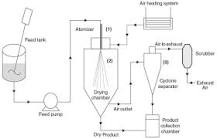

What are the spray dryer parts and function?

A spray dryer consists of a feed pump, atomizer, air heater, air dispenser, drying chamber, and systems for exhaust air cleaning and powder recovery/separator. The three stages that occur in a spray dryer before drying is accomplished include: Atomization. Spray-air mixing and moisture evaporation.

What is the size range of particle produced from spray drying?

The droplets lose moisture rapidly and dry when they meet a stream of hot gas. The drying occurs in an insulated chamber. Powders produced have relatively uniform characteristics and are collected from the spray dryer. Spray drying usually provides particles with a mean particle size below 10 μm, preferably 5 μm.

How do you calculate powder yield?

Powder yield was calculated simply as the mass of the powder out of the spray dryer divided by the mass of excipients originally spray dried multiplied by 100.

How long does spray drying take?

3.2 Spray Drying Drying is accomplished within a few seconds. The dried product is removed from the bottom of the tower, and the waste gas stream exhausted through a cyclonic dust separator.

What is the difference between a dryer and a spray dryer?

Spray dryers can dry very quickly compared to other methods. They also turn a liquid into a dried powder in a single step, which simplifies and improves profit margins. The development of spray drying equipment and techniques evolved from the 1870s through the early 1900s.

What is the main difference in using single two and three stage spray dryer?

Two Stage Spray Dryer – spray dryers followed by fluid bed dryer for drying products which require longer residence time & product conditioning post drying. Three Stage Spray Dryer – spray dryers with Internal fluid bed followed by external fluid bed dryer for producing dust free agglomerates.

Which product is not dried by a spray dryer?

| Q. | Which product is NOT dried by spray dryer? |

|---|---|

| B. | Fruit Juice |

| C. | Lactose |

| D. | Bacterial & viral cultures |

| Answer» d. Bacterial & viral cultures |

What is the feed introduced in the spray dryer?

With what is the feed introduced in the spary dryer? Explanation: A spray dryer is used to dry the atomized droplets of a feed that may be a solution or a slurry of fine particles. It consists of a big drying chamber in which the feed is introduced through an atomizer at the top.

What is spray dryer machine?

Spray dryers are rapid dryer, drying rate is high. Product quality can be controlled and maintained in drying process. Highly controllable drying systems flow of hot air, droplet speed and droplet temperature can be effectively controlled. Fine droplets shaped offers more surface area for heat and mass transfer.

What is spray dryer PDF?

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.

How do you determine the efficiency of a dryer?

Thus if dryer efficiency ηis expressed as latent heat of evaporation divided by actual heat supplied to the air, this is (103/130) or approximately 80%, so that 20% is inherently lost in the exhaust. This efficiency will vary with inlet air temperature, falling further for lower inlet temperature.

How do you increase bulk density in a spray dryer?

Increasing residual moisture content increases bulk density. Increasing inlet air temperature decreases bulk density. Reducing the outlet air temperature increases residual moisture and therefore increases bulk density.

What is aspiration rate in spray dryer?

According to this article, Aspiration rate is the % of inlet air flow used to the maximum air flow the spray dryer can reach. Suppose the inlet air flow you are using is 60cfm and the maximum cfm the spray dryer can reach is 140cfm, so aspiration rate is (60/140)*100.

What is spray dryer machine?

Spray dryers are rapid dryer, drying rate is high. Product quality can be controlled and maintained in drying process. Highly controllable drying systems flow of hot air, droplet speed and droplet temperature can be effectively controlled. Fine droplets shaped offers more surface area for heat and mass transfer.

What is spray dry technology?

Spray-drying is a rapid, continuous, cost-effective, reproducible and scalable process for the production of dry powders from a fluid material by atomization through an atomizer into a hot drying gas medium, usually air.

How long does spray-drying take?

3.2 Spray Drying Drying is accomplished within a few seconds. The dried product is removed from the bottom of the tower, and the waste gas stream exhausted through a cyclonic dust separator.