Spray drying is the process of creating a dry powder out of a liquid or slurry through rapid drying with a hot gas. For many thermally-sensitive materials such as those used in the food and pharmaceutical industries, this is the preferred drying method. Spray dryers can dry very quickly compared to other methods.

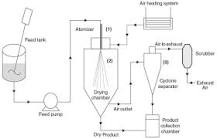

What is the process of spray drying? The spray drying process involves the atomization of a solution, slurry, or emulsion containing one or more components of the desired product into droplets by spraying followed by the rapid evaporation of the sprayed droplets into solid powder by hot air at a certain temperature and pressure.

How long does spray drying take? 3.2 Spray Drying Drying is accomplished within a few seconds. The dried product is removed from the bottom of the tower, and the waste gas stream exhausted through a cyclonic dust separator.

What are the advantages of spray drying? Benefits of Spray-Drying Some of the advantages of spray-drying include its ability to be fully automated and continuous. Short residence times and suitability for both heat-sensitive and heat-resistant foods are other advantages. The technology is suitable for a variety of feed materials, provided they are pumpable.

What is spray drying equipment?

What temperature is spray drying? The typical spray drying process used today employs air heated up to 400° Fahrenheit to dry an atomized liquid into a powder.

What is spray drying in industry? – Related Questions

How can you increase the efficiency of spray drying?

Spray drying energy efficiency can be improved by widening the gap between inlet and outlet temperatures and adding heat recovery equipment. For many years, spray drying has been one of the most energy-consuming drying processes, yet it remains one that is essential to the production of dairy and food product powders.

What is the difference between spray drying and freeze-drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

How many types of spray dryers are there?

… Among them are the rotary, nozzle, two-fluid, pressure and ultrasonic nozzle (Walzel, 2011). Atomization is a crucial part of the spray dryer because it influences the drying rate, particle diameter, particle distribution, and dispersibility of the powder for rehydration (Chegini & Taheri, 2013) .

How efficient is spray drying?

The hot air is used as the drying medium in spray dryer. It was reported that the heat efficiency of spray dryer is about 25% to 60%, and some even are below 20%[1].

Which product is dried by spray dryer?

Spray dryer is used in drying pharmaceuticals like penicillin, blood products, enzymes, vaccines, etc. 2. It is used in the production of excipients and co-processed excipients with increased flowability, compatibility, and tablet disintegration.

What are the advantages of spray?

Spray paint offers more even coverage without brush strokes. Spray primer is a million times faster than brush primer. Spray paint is a million times faster than brush on paint. Spray paint is typically oil based, therefore more durable than water based spray or regular latex paint.

What is spray dryer PDF?

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.

What is the size range of particle produced from spray drying?

The droplets lose moisture rapidly and dry when they meet a stream of hot gas. The drying occurs in an insulated chamber. Powders produced have relatively uniform characteristics and are collected from the spray dryer. Spray drying usually provides particles with a mean particle size below 10 μm, preferably 5 μm.

What is atomizer in spray dryer?

In spray dryers, atomizer system is much like a knife that needs to cut fluid particles precisely into finar parts, and if the automizer fails, it can have serious consequences. Atomization system works to chop up the liquid droplets into even finer droplets in order to serve the higher surface area to volume ratio.

WHAT DOES A to Z drying do?

Founded in 1972, A to Z Drying, Inc. offers custom spray drying, blending, packaging and warehousing to customers. A to Z Drying, Inc. is proud to provide cost-effective manufacturing for biotechnology companies including industry leaders in biorational solutions.

What is the principle of FBD?

Fluid bed dryers work on the principle of fluidization, a process where a material is converted from a static solid-like state to a dynamic fluid-like state. In this process, hot gas or air is introduced through a perforated distribution plate into the area holding the material.

Who invented spray dryer?

Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [1, 2, 3]. Ever since it was first discovered, the spray-drying technique has been improved concerning its operational design and applications.

What may be the factors affecting spray drying?

Scope and approach: Product yield and physical properties of the final powder are affected by various factors, including carrier material and its concentration added into the feed, feed flow rate, atomization speed/pressure, and drying temperature.

Is spray drying cheap?

Generally, spray drying is a cheaper, faster and more energy efficient alternative to freeze drying.

Why freeze drying is expensive?

Freeze-drying: The Basic Process Freeze-drying operation is based on sublimation, which is the transformation from ice to vapor without passing through the liquid phase. Sublimation process makes freeze-drying operation expensive to use.

What is spray freeze drying?

Another alternative approach in preserving phages in a solid form is by using spray-freeze drying. Spray freeze-drying involves spraying a formulation into a cold medium and drying under vacuum and temperature conditions similar to lyophilization.

Which gas is used in spray drying?

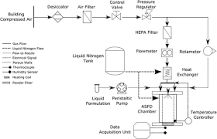

Air is the heated drying medium; however, if the liquid is a flammable solvent such as ethanol or the product is oxygen-sensitive then nitrogen is used.

What is spray drying in food preservation?

Spray drying is the process where a mixture of compounds is made in its liquid or slurry form that is finally converted into dry powder form. This drying technique emerged way back in 1860s and was used during World War II. It helped to make easy shipment of larger quantities of food within limited storage area.

What is the difference between spray drying and freeze drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

What is spray drying of milk?

Spray drying is a major process of water removal and particle formation in milk powder production. The principle of spray drying is to remove the water from the milk concentrate as fast and at as a low temperature as possible so as to minimize heat damage to the milk solids.