Nozzle pressure is directly related to the velocity of the stream. For the given example, instead of a stream speeding through the fire’s super-heated gases at 80 mph, it goes through at 60 mph.

What are the different types of nozzles used in the sprayers? Nozzle Description. Nozzle types commonly used in low-pressure agricultural sprayers include flat-fan, flood, raindrop, hollow-cone, full-cone, and others. Special features, or subtypes such as “extended range,” are available for some nozzle types.

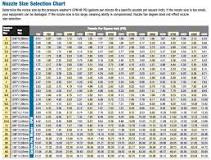

How do I choose a sprayer nozzle? The best method for choosing the correct nozzle tip size is to determine the gallons per minute (GPM) of nozzle output required and then select a nozzle tip size that, when operated within the recommended pressure range, will provide this flow rate.

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What are the 2 types of nozzles? The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

How do I choose a nozzle size? The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

What is nozzle pressure? – Related Questions

What do the numbers on spray nozzles mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

How do you read a nozzle chart?

On a standard nozzle chart, the top column that runs left to right is the pressure that you want to obtain. The left column top to bottom is the nozzle orifice size designation. The top to bottom column next to the orifice size column indicates the actual orifice measurement.

How will you select a nozzle for a particular type of job?

- Select the application rate in gallons per acre (gpa). …

- Select a practical and safe ground speed in miles per hour (mph).

- Determine the spray width per nozzle (W).

- Determine the flow rate (gpm) required from each nozzle by using the following equation:

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

Which is the mostly used nozzle?

Round Nozzle It is the most used nozzle by the bakers around the world.

Do nozzles increase pressure?

In a convergent nozzle, there is an increase in velocity and a decrease in pressure, but we know that pressure is inversely proportional to area.

What is nozzle size?

Nozzles are manufactured specifically for each machine’s volume and pressure. This means that each nozzle size has a different size orifice (or opening). There are a variety of sizes but the most commonly used are between 3.0 to 6.5, sized in . 5 increments.

What is nozzle and its types?

A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them.

What is a cone nozzle used for?

Solid cone nozzles are suitable for application of residual herbicides and systemic insecticides using a knapsack or boom mounted or for spot applications of herbicides. They produce a full cone spray pattern with coarse droplets at a pressure of 1 – 10 bar.

Does a bigger nozzle print faster?

The larger nozzle diameter will offer faster print speeds and allow more efficient toolpaths. The standard 0.8mm walls will now only require a single pass to lay down. I think this is a case where the larger 2.85mm filament offers some much-needed leeway.

How do you calculate flow rate of a nozzle?

- Any nozzle will produce certain flow rate at a given pressure differential. …

- The flow rate for a given nozzle can be calculate by the following formula.

- Q= Flow rate.

- K = K factor for nozzle.

- P = Pressure differential at the nozzle.

- n = Is a constant that depends upon the spray pattern type.

Can you print 0.2 mm with a 0.4 mm nozzle?

So for a 0.4mm nozzle, you’ll be looking to print at 0.2mm layer height, or up to 0.3mm. Your minimum would want to be around 0.1mm, any lower than this and you’re just increasing your waiting time for not much benefit (on the same 0.4mm size nozzle).

What is a 311 spray tip used for?

6 inch spray pattern ideal for narrow surfaces such as fences, decks and furniture. The . 011 inch hole size optimal for spraying thinner materials like semi transparent stains, water sealers, stains or polyurethanes.

How is nozzle pressure measured?

The nozzle pressure can be measured with a gauge placed on a nozzle body. Simply purchase a quality gauge and a threaded nozzle cap, combine the two and install in place of a nozzle. A pressure gauge threaded into a nozzle cap can measure boom pressure.

How many types of nozzle are there?

There are 5 basic spray pattern types: flat fan, solid stream, full cone, hollow cone and mist/fog. Various nozzle designs are deployed to create these patterns and details on each can be found in the sections below.

How high should a sprayer boom be off the ground?

This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

Which type of nozzle should be used for the spraying of pesticides?

Fan Nozzles The most common type of nozzle used in agriculture is the fan nozzle. A fan nozzle is widely used for spraying pesticides — both banding (over and between rows) and broadcast applications. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2).

What could cause a knapsack sprayer to leak at the bottom?

Possible Causes for Leaks The most common reason sprayers leak is a worn or damaged component, whether that be a valve or an O-ring.

What are the different types of fire nozzles?

- Smooth or solid bore.

- Fixed orifice or single gallonage (sometimes called variable pressure/variable flow)

- Selectable or adjustable gallonage.

- Automatic or constant pressure.

- Multi-purpose nozzle (combination smooth bore and fog)

Which type of nozzle should be used for spraying pesticides?

Fan Nozzles The most common type of nozzle used in agriculture is the fan nozzle. A fan nozzle is widely used for spraying pesticides — both banding (over and between rows) and broadcast applications. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2).

How many types of nozzles are used in engine?

Two basic types of injection nozzles are manufactured: pin nozzles – designated DC, DN ; mostly used in engines with indirect fuel injection (engines with precombustion chamber) hole nozzles – designated DO, DL, DOP, DLLA; used in engines with indirect fuel injection.

What are the different types of spray bottles?

There are two basic types of refillable spray bottles: I) metal bottles that spray product using compressed air and 2) plastic bottles that use a hand pump to spray product. Refillable metal bottles more closely resemble aerosol cans in terms of their design and performance.