A Counter Pressure Filler (also known as an Isobaric Filler) is a device used to fill bottles or aluminum cans from a pressurized or non-pressurized bulk storage tank without losing carbonation. Brewers, sparkling wine makers, and soft drinks manufacturers use these devices to bottle carbonated drinks for retail sale.

How do you fill aerosol?

What is a liquid filling machine? A liquid filling machine is a machine that can be used to fill any kind of bottle or container with a specified and precise volume of liquid. The Kinex Relia-Fill™ is an easy to use liquid filling machine that fills bottles quickly and accurately.

What are the different types of beverage filling machine?

- Manual liquid filling machine.

- Semi-automatic liquid filling machine.

- Automatic water filling machine.

- Inline liquid filling machine.

- Rotary liquid filling machine.

- Piston liquid filling machine.

What is linear filling machine? AUTOMATIC LIQUID FILLING MACHINE (LINEAR) Machine is designed to fill various types of liquid in various types of containers. Machine works on volumetric principle. Adjusting the displacement of piston can set a fill volume. Machine has conveyor and container indexing mechanism synchronized with filling operations.

Can you refill canned air?

What is counter pressure filling? – Related Questions

Are aerosols banned?

The U.S. banned CFC’s in the 1970’s. The Clean Air Act further restricted use of CFC’s in the U.S., and most of the world followed suit. Since CFC’s were banned, all aerosol products made in the U.S. now use propellants, such as hydrocarbons and compressed gas that do not deplete the ozone layer.

How does a volumetric filling machine work?

A volumetric filling machine fills containers with a consistent volume of the product through a time-based filling principle. Regardless of the discrepancies in your containers’ interior volumes, volumetric fillers will make sure that each container is filled with the same amount of product.

What is a capping machine?

A capping machine’s main function is to apply a metal or plastic thread lid, snap, or caps accurately and securely to a container or bottle. Capp closing machines also process plugs and other similar closures. These systems ensure sanitary workspaces, high production speeds, and affordable manufacturing costs.

What is gravity filling?

Gravity filling is the simplest filling method. The uncomplicated construction and operation of gravity filling machines permits them to run with a minimum of maintenance. The supply tank (more properly called the filler bowl) is the upper, central part of the machine.

What are the filling equipment?

- Liquid Filling Machines.

- Powder Filling Machines.

- Vibratory Weigh Filling Machines.

- Capsule Filling Machines.

- Positive Displacement Pump Filling Machines.

What are the uses of filling machine?

Filling machine is packaging machinery to fill the product into bag, pouch, or containers such as bin or bottle. The types of filling machine differ depending on the products of liquid, paste, granule and powder.

Which machine is designed for filling of pellets?

SF-40N Capsule Filler The SF-40N capsule filling machine is used for various industries like chemical, pharmaceutical, animal food and food. This machine can produce a maximum of 40,000 cap/hr. For pellet filling, the maximum capacity is 31,500 cap/hr.

How do you recharge aerosol cans?

How do you make a refillable compressed air can?

How much PSI does canned air have?

The maximum pressure for an aerosol can is typically 10 bar (145 psi) at 20 °C (68 °F).

Is aerosol still bad?

Typically, all aerosols contain chemicals compounds which in one way or another, are harmful to the environment. Chemicals from aerosols are toxic when they contaminate water, soil, and other natural environmental elements.

What is the problem with aerosol?

All aerosol cans can create potentially harmful effects on the environment. The chemicals used inside of them are toxic to the soil, air, and water. This old-fashioned method poses risks to the environment, including pollution, which is one of the leading causes of global warming and acidic rain.

Why people must not use aerosol sprays?

Many aerosol sprays contain highly toxic chemicals like xylene and formaldehyde – yes the same chemical used to preserve anatomical specimens in a jar. These toxic ingredients also include neurotoxins and carcinogens that are extremely hazardous for adults, children and family pets.

How do you make a filling machine?

How does a vacuum filler work?

How it works: When Filling nozzle inserted into an empty bottle, the sealer seals the bottle and air in the bottle is pulled out by vacuum pump. The vacuum in the bottle then sucks liquid into the bottle.

How does a vacuum bottle filler work?

Vacuum level semi-automatic filling machines use the rim at the top of the container to form an airtight seal around the filling nozzle. This airtight seal creates a vacuum within the bottle which draws free-flowing liquids from a supply tank into the bottle, via specially designed nozzles.

How do you make a capping machine?

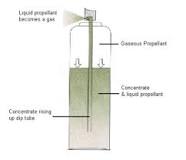

How do aerosol cans work?

When the liquid mixture is released from the aerosol, the liquid propellant becomes a gas and helps break up the product into a fine mist. In foams like mousse and aftershave, the liquid gas forms bubbles, making the product expand as it is released from the aerosol.

How do you pressurize a spray can?

You’ll want to push the nozzle of the can open while blowing air through, give or take about 10 seconds. Remember: a depressurized can starts at atmospheric pressure (about 14–15 psi), while your blow gun is backed by 100+ psi.

What are examples of aerosols?

Some common examples of aerosols include volcanic ash, pollen, sea spray, and sulfates from power plants. Aerosols can be classified into types based on the size of the airborne particles, their source, or their place of residence in the atmosphere.

What is aerosol used for?

In addition, aerosols are used in healthcare as disinfectants, inhalers, anesthetic preparations, etc. Household preparations in aerosol cans include air fresheners, cleaning agents, car cosmetics, paints and varnishes, etc. Last but not least, certain foodstuffs, such as oil or whipped cream.