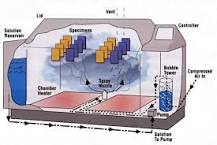

The ASTM B-117 salt spray test uses a closed testing chamber in which a salt water (5% NaCl) solution is atomized by means of spray nozzles using pressurized air. The test subject is continuously exposed to the same corrosive atmosphere inside the chamber, then evaluated after removal from the environment.

How do you perform a salt spray test? Salt spray tests are conducted in a closed testing chamber. A salt water solution is applied to a sample via a spray nozzle. This dense salt water fog is used to imitate a corrosive experiment. After a period of time, which is dependent on the corrosion resistance of a product, the appearance of oxides is evaluated.

What is a salt spray chamber? A salt spray chamber creates a highly corrosive environment to test the long-term effects of salt on objects and materials. About Our Salt Spray Chambers. The MX Series is AES’s salt spray chamber. It’s the only test chamber on the market that provides a 360-view into the chamber.

Which material is used for salt spray testing? Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested) and finished with a surface coating which is intended to provide a degree of corrosion protection to the underlying metal.

What is salt spray test for zinc plating? The salt spray test is the exposure of the surface coating to a fine mist containing 5% sodium chloride, for a given time, at room temperature. For galvanized steel, the spray test, ASTM B117, accelerates the wrong corrosion mechanism. The salt spray attacks the bare zinc.

What is the purpose of the salt spray test *? A salt spray test is a corrosion testing method that uses high-saline environments to measure the corrosion resistance of products, paints and coatings over extended periods.

What is ASTM b117? – Related Questions

How does a salt spray machine work?

This testing machine contains a chamber where the saltwater solution is automized by utilizing the air pressure. It will lead to dense water fog inside the chamber. When the specimen will be placed inside the chamber then the rate of corrosion will be displayed through which it can withstand.

What are salt spray hours equivalent to in years?

Some references indicate that approximately 100 hours salt spray is similar to one year outdoors based on OEM testing in the US.

How do you test for corrosion resistance?

A primary testing method is Salt Spray testing, which as its name indicates, evaluates how resistant a part or material is to corrosion when exposed to a salt spray for extended periods of time. Effective Salt Spray testing must be performed in a controlled environment, such as a closed salt fog tank.

Is standard for salt spray test?

ASTM B117 salt fog or salt spray testing is a very popular corrosion test designed to provide corrosion resistance information on metals and coated metals. The ASTM B117 test standard has also been approved for use by Department of Defense agencies.

What is white rust in salt spray test?

White rust is nothing but failure phenomena of coated surface and Red rust is failure phenomena of parent material. White rust and Red rust can be decided by the nature of coating. Generally salt spray specification for white rust will be 46 hrs and red rust will be 120 hrs, of course depends on nature of coating.

What is neutral salt spray test?

Salt spray testing is a common accelerated corrosion test method that exposed metallic and non-metallic materials to a highly corrosive environment, over an extended period of time, in order to assess their relative corrosion resistance.

Where is salt spray test used?

It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion. Also known as salt fog testing, it is one of the oldest testing methods used in the HVAC-R coatings industry, and for this reason, is often referred to when selecting HVAC-R coatings.

What is SST in powder coating?

Salt Spray Test (SST) is a really widespread corrosion method, applied in order to check materials and surface coatings corrosion resistance.

Is salt spray acidic?

It is a strong and corrosive acid that is used to accelerate the corrosion of metal surfaces. Saline solution is a mixture of salt and water used to generate the salt spray in the test. It is also known as sodium chloride solution.

Is salt spray a destructive test?

To conclude, the salt spray test unfortunately has serious drawbacks. It is a destructive test, very scattered and not correlated with actual performance.

How do you run a salt spray chamber?

What is water spray test?

The spray-test determines the water repellence of each type of fabric, treated or not treated with a water repellent finish. It is an easy to use test, which gives quick results and meets the ISO 4920 standard.

How do you make salt fog?

- Assemble the chamber and fill it with a 5% saline solution.

- Turn on the heater programed to 100 degrees F, and turn on fogger.

- Let stabilize at temperature and verify/observe fogging.

- Qualify the chamber with your Engineering Department.

- Start running samples with time evaluations.

What is Ruspert coating?

Ruspert metal finish is a high-grade, non-organic, tri-layered ceramic surface coating developed to attain optimum perfor-mance in the various pollutive and atmospheric conditions that cause corrosion. It consists of three layers: The 1st layer: a metallic zinc layer.

What are the 3 types of corrosion?

- Uniform Corrosion. Uniform corrosion is considered an even attack across the surface of a material and is the most common type of corrosion. …

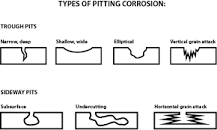

- Pitting Corrosion. …

- Crevice Corrosion. …

- Intergranular Corrosion. …

- Stress Corrosion Cracking (SCC) …

- Galvanic Corrosion. …

- Conclusion.

What are corrosion testing methods?

- Immersion Testing. …

- Visual Examination. …

- Salt Spray / Fog Testing. …

- The Weathering Test. …

- Electrochemical Testing. …

- Corrosion Coupons. …

- Ultrasonic Thickness Monitoring. …

- Electrical Resistance Testing.

What metal is most resistant to corrosion?

1. Stainless steel. Stainless steel alloys are renowned for the corrosion-resistance, ductility, and high strength.

Does salt rust stainless steel?

Stainless steel can, in fact, rust and corrode if continuously exposed to saltwater or other corrosive conditions over time.

How do you run a salt spray chamber?

Is standard for salt spray test?

ASTM B117 salt fog or salt spray testing is a very popular corrosion test designed to provide corrosion resistance information on metals and coated metals. The ASTM B117 test standard has also been approved for use by Department of Defense agencies.

How do you test for metal corrosion?

A primary testing method is Salt Spray testing, which as its name indicates, evaluates how resistant a part or material is to corrosion when exposed to a salt spray for extended periods of time. Effective Salt Spray testing must be performed in a controlled environment, such as a closed salt fog tank.

How is corrosion test done?

- Immersion Testing. …

- Visual Examination. …

- Salt Spray / Fog Testing. …

- The Weathering Test. …

- Electrochemical Testing. …

- Corrosion Coupons. …

- Ultrasonic Thickness Monitoring. …

- Electrical Resistance Testing.