A pressure sprayer is a chamber which is filled with a liquid which can be a lubricant, paint or chemical, then filled with compressed air to allow the liquid to be sprayed at pressure. Units are typically of cast iron or stainless steel design.

What are the parts of knapsack sprayer? It consists of a piston type pump, a platform with fork, a lever to operate the pump, pressure chamber, suction hose with strainer, delivery hose, and a spray gun with flow control knob and nozzle.

What pressure should a sprayer run at? The normal recommended operating pressure for regular flat-fan nozzles is 20 to 30 psi. At these pressures, this nozzle type will produce medium to coarse drops that are not as susceptible to drift as the finer drops produced at pressures of 40 psi or greater.

How do you pressurize a spray bottle?

How high should a sprayer boom be off the ground? This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

What are the 4 main sprayer components? The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What is a pressure sprayer? – Related Questions

What is the function of plunger rod in knapsack sprayer?

It is a hydraulic energy sprayer. It has a hydraulic pump inside the container, with cylinder, plunger and a plunger rod. By operating the plunger up, the spray fluid in the container is sucked into the cylinder through a ball valve assembly and then pressurised during the downward stroke.

How much air does a spray gun need?

What is the best air pressure for spray painting? Again, it’s essential you check your specific model’s recommendations, but your HVLP spray gun PSI will likely sit between 25-30 PSI for something like using an air compressor for spraying cars, rising to 40 PSI in some cases where higher atomisation is needed.

How much pressure should a pump sprayer have?

Most hand pump sprayers are limited to about 40 psi.

How much psi does a pump sprayer have?

The hand held sprayer has a plastic compression pump that is sealed with rubber O-rings. The compression pump is hand actuated to an operating pressure of 40 PSI.

How do you fix a spray bottle that won’t pump?

Unblock the Nozzle If not, unscrew and remove the cap and hold it under hot, running water or immerse it in vinegar, then use a pin to poke a hole in any blockage in the nozzle itself. If your bottle contains hairspray, soak the nozzle in alcohol.

How do you pressurized spray can?

How does a spray bottle pump work?

This pump is attached to a plastic tube that draws cleaning fluid from the bottom of the reservoir inside the bottle. The pump forces this liquid down a narrow barrel and out a small hole at the spray valve. Inside the shroud, there is a small spring which compresses the fluid once pulled back by the trigger.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

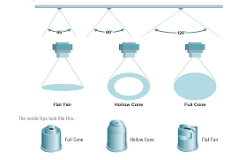

How do I choose a nozzle for my sprayer?

You’ll want to determine the nozzle flow rate at gallons per minute (gpm). To find that, start with your application rate in gallons per acre (gpa). Next, find an efficient and safe ground speed in miles per hour (mph). Then, determine the spray width per nozzle (W).

What do the numbers on a sprayer nozzle mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

What is spray volume?

The correct volume of spray is the sprayer application rate multiplied by the number of acres. Example. You want to spray a 12-acre field and your sprayer applies 20 gallons per acre. Gallons of spray mixture = application rate (gallons per acre) × area to spray (acres) Therefore, put (20 × 12 =)

What is high volume spray?

High volume low pressure refers to a type of applicator used to spray paint on a surface to be coated for corrosion protection. High volume low pressure (HVLP) sprayers operate on the basis of vacuum creation and turbine support.

What are the three classifications of sprayers?

There are three types of Knapsack sprayers i.e battery, manual and battery cum manual sprayer.

What is the tank for in a knapsack sprayer?

Knapsack sprayers have tanks of fertilizer, insecticide or herbicide that gardeners wear on their backs to spray gardens or trees. The gardener controls a nozzle with his right hand and a pump handle with his left hand to keep up the pressure in the tank.

What is the function of spray lance?

The spray lance is ideal for watering small and medium-sized and gardens. The perfect combination of elegance, first-class features and perfect ergonomic design make the Spray lance from Kärcher ideal for effortless watering even for longer watering tasks. In brief: the ideal solution for numerous uses in the garden.

What is the function of Lance in knapsack sprayer?

The object of the homogeneous application of a spray mixture at the same time low application varieties is solved by a lance, which has a distance control in the region of the output-side connection for keeping constant the working height.

What causes orange peel when spraying?

What is the orange peel effect in paint? The name orange peel is given by the resemblance of the final paint finish to an orange peel. This problem is caused by the lack of stretching or levelling of the paint, resulting in a deformed surface and in an increased thickness of the final coat.

Do you need a regulator on spray gun?

It’s a good idea to have a regulator on or close to the gun, to mitigate any pressure drops in your system across air lines, and to be able to tune your gun’s spray pattern based on the type and viscosity of material you’re shooting.

What PSI should I spray primer?

You want to set it with the trigger pulled. To begin, set it at 50 psi. Close the air volume control knob (usually located beside where the air hose enters the gun) and with the trigger pulled, open it to the point where the air volume starts to stay the same, and then stop.

How far will a pump up sprayer spray?

The range of a pump sprayer depends on the spray pattern. It will spray the farthest when set to a narrow stream. Most pump sprayers can spray up to 20 feet, and some more powerful sprayers are capable of reaching 30 feet.

How far can a backpack sprayer spray?

How far can a backpack sprayer spray? This depends on the pack, but most can handle between 10 and 30 feet, with an average of 20 feet.

How does pressure affect droplet size?

Increased pressure and increased fluid temperature both decrease droplet size. Increased viscosity and increased surface tension both decrease droplet size. Knowing these factors, you can increase or decrease the droplet sizes to suit the specific needs for each situation.

Why is it not recommended to use pressure adjustments to change nozzle flow rate?

However, pressure should not be used to make significant changes to flow rate. It takes a 4x change in pressure for a 2x change in flow rate, so it’s inefficient. Operating pressures at the upper or lower limit of a nozzle’s range can have undesirable impacts on nozzle wear, median droplet size and swath uniformity.

How do you depressurize a roundup sprayer?

DEPRESSURIZE- Push pump handle all the way down and turn pump handle and cap counter-clockwise to relieve pressure, then re-tighten prior to storing.

What are the functions of a knapsack sprayer?

Knapsack sprayers are used for spraying insecticides and pesticides on small tress’ shrubs and row crops upto 2.5 m height. Features: It consists of a frame on which fuel tank, engine and hose with cut-off mechanism are mounted.

What is a knapsack sprayer?

Definition of knapsack sprayer : a spraying apparatus consisting of a knapsack tank together with pressurizing device, line, and sprayer nozzle, used chiefly in fire control and in spraying fungicides or insecticides.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

How do you use a knapsack sprayer?

- Fill the knapsack sprayer with water (for instance 10-L).

- Add herbicide (say, 50 or 100 ml).

- Cover the sprayer and shake vigorously.

- Fill the sprayer with more water (eg 5-L more) until it is full.

- Spray the weeds with your herbicide solution.