Commercially, plunger pumps are commonly used in cleaning, disinfection, pest control, agriculture, and other applications in their electrically powered equipment such as pressure washers, misters and sprayers.

What is a piston pump sprayer? Piston sprayers include a cylinder housing in which, when pumping, a piston moves up and down to create pressure. Most piston models can reach up to 90 psi. Higher psi delivers smaller droplet size and has a further reach. Use with low abrasive, low viscosity spray liquids such as herbicides and insecticides.

What’s better a diaphragm or a piston pump sprayer? Piston pumps work best with lighter chemicals, such as herbicides and insecticides. Diaphragm – Diaphragm pumps don’t deliver as much pressure as piston, making them ideal for use in close application scenarios such as weed killing. But the diaphragm pump is more durable to chemical damage.

What is the difference between a piston pump and a diaphragm pump?

How does a piston diaphragm pump work? Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

How does a pump sprayer work? The pump forces this liquid down a narrow barrel and out a small hole at the spray valve. Inside the shroud, there is a small spring which compresses the fluid once pulled back by the trigger. The moving piston compresses the spring, so when you release the trigger, the piston is pushed back out of the gasket.

What is a plunger pump used for? – Related Questions

How does backpack sprayer work?

How does a diaphragm airless paint sprayer work?

Diaphragm pumps In a diaphragm pump, a rod powered by a motor operates diaphragms that expand and contract, taking in fluid through the inlet valve and expelling it out of the gun.

What is positive displacement pump?

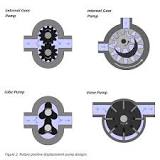

What is a positive displacement pump? A positive displacement (PD) pump moves a fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

What is the difference between plunger and piston pump?

From an engineering standpoint, it’s easy to understand that the main difference between piston and plunger pumps is the placement of the seals or O-rings. Again, the plunger pump’s seal is stationary while the piston pump’s seal moves with the piston.

What is a diaphragm pump used for?

Because diaphragm pumps are so versatile, they are used in virtually every industry that requires fluid transfer. They are often used for dewatering or water removal across many different industries. They are used for filling, dispensing and metering due to their efficiency and accuracy.

What are the disadvantages of a diaphragm pump?

| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

How does a pneumatic piston pump work?

As the motor pulls up the rod, the piston creates suction at pump intake. Liquid is pulled through a strainer into the foot valve. Stainless-steel balls in the reciprocating piston and foot valve open naturally to allow liquid into the piston, then close to prevent liquid from returning.

Can you flow through a diaphragm pump?

WHAT KIND OF FLUID DOES A DIAPHRAGM PUMP TRANSFER? Diaphragm pumps will move nearly any kind of fluid. Some common examples of fluids pumped using a diaphragm pump are water, oil and acid. Diaphragm pumps are capable of pumping high viscosity fluids from adhesives and gear oils to hand lotions, surfactants and resins.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

How much pressure should a pump sprayer have?

Pumping the handle or lever of your sprayer builds the pressure inside the sprayer tank. This pressure pushes the liquid out of the sprayer gun when the trigger is pulled. Most hand pump sprayers are limited to about 40 psi.

How do you release pressure from a pump sprayer?

- Turn the tank upside down.

- Squeeze the flow control lever until all the air pressure is gone.

- If your sprayer has a pressure relief valve, turn knob clockwise until all air pressure is gone.

How far will a backpack sprayer spray?

How far can a backpack sprayer spray? This depends on the pack, but most can handle between 10 and 30 feet, with an average of 20 feet.

What is backpack sprayer?

: a spraying apparatus consisting of a knapsack tank together with pressurizing device, line, and sprayer nozzle, used chiefly in fire control and in spraying fungicides or insecticides.

How does a piston paint sprayer work?

Can you spray oil based paint with an airless sprayer?

Airless pain sprayers work with oil-based paint or stain. HVLP paint sprayers work with oil-based paint, but thicker paints such as water-based latex can clog the sprayer.

What PSI should latex paint be?

For spraying latex paint, there are two pressures to keep in mind, depending on what you are painting: A 26 – 29 PSI is suggested for a base coat on the surface being painted; A clear coat is better served by a lower 2 – 3 PSI for better atomization (remember that from earlier?) and flow.

What are the 2 types of pumps?

Main Types of Pumps: Centrifugal and Positive Displacement.

What are the 3 types of positive displacement pumps?

The main different types of Positive Displacement Pumps are; Progressive Cavity Pump (PC Pump) Gear Pump – Internal & External. Vane Pump (Impeller Pump)

What are the 3 types of centrifugal pumps?

Single-stage, Two-stage, or Multi-stage.

How does a linear air compressor work?

Linear compressors work similarly to a solenoid: by using a spring-loaded piston with an electromagnet connected to AC through a diode. The spring-loaded piston is the only moving part, and it is placed in the center of the electromagnet.

What is positive displacement pump?

What is a positive displacement pump? A positive displacement (PD) pump moves a fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.