Boomless nozzles are used for spraying areas not easily accessed with a boom. Choose from single brass, stainless steel, nylon nozzles or the double-sided BoomJet suited for large capacity 12 volt or medium pressure diaphragm pumps. Boomless nozzles can spray widths from 3 to 19 metres.

How do you make a boom sprayer?

How do you make a ATV boom sprayer?

What are the components of a boom sprayer?

- Hose Drops & Hose Swivels. 19 items.

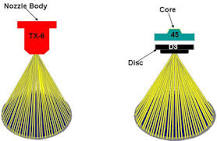

- Nozzle Bodies. 300 items.

- Nozzle Body Boom Clamps. 23 items.

- Tip Screens & Tip Check Valves. 55 items.

How far off the ground should a boom sprayer be? This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

How do you make a homemade sprayer?

What is a Boomless spray nozzle? – Related Questions

How do you make a tank sprayer?

How do you make homemade foam markers?

How do you make an electric sprayer?

How do Boomless spray nozzles work?

A boomless sprayer generally has one or two nozzles that can be pointed out sideways or tilted slightly up and spray out further achieve coverage. A boom sprayer typically has multiple spray tips spread out along both boom arms with even spacing and are pointed straight down towards the target.

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What is the HP power required for power sprayer?

POWER SPRAYER It can be powered by a 3 HP engine or electric motor .

What are the disadvantages of sprayer?

Disadvantages :1. Low efficiency and large labor intensity are not suitable for large-scale operation. 2. The liquid has run, run, run, leak and drip phenomenon.

How many nozzles does a boom sprayer have?

Five nozzles can produce the required flow, each at different pressures.

What is the standard nozzle spray angle?

The most common spray angles are 65 degrees, 80 degrees, and 110 degrees. Recommended nozzle heights for flat-fan nozzles during broadcast application are given in Table 1.

Which nozzle is best for herbicide spray?

Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides.

How do you calibrate a sprayer boom?

- Select a travel distance from Table 1 based on row spacing. …

- Drive 136 feet and measure the time in seconds.

- If it took 15 seconds, catch the output from each of the three nozzles for 15 seconds. …

- Repeat Step 3 for each set of nozzles on the boom to make sure the application rate is uniform across the boom.

How do you make a herbicide sprayer?

How do you make a paint sprayer?

How do you make a water spreader?

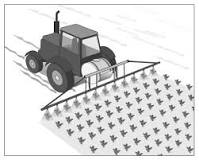

How does a boom sprayer work?

A boom sprayer is the most common type of apparatus for applying herbicides in broadscale farming. A sprayer has many components, the most important being the nozzles, which split the herbicide into many small droplets that are projected through the air to the target.

How does a roller pump work?

The pump operates by receiving a fluid through the inlet port where it is captured and transported by the rollers, and then expelled through the outlet port. Construction features include housings and rollers, which are made in a variety of materials in order to be resistant to a wide range of chemicals.

How do you make foam sprayer?

How do you make sprayer marker foam?

How does a foam marker on a sprayer work?

Boom-end foam markers utilize a device mounted onto the end of the boom to generate long-lasting foam. By generating the foam output at the end of the boom, the waiting period is decreased between the time it would take foam to travel from the point of being generated to the end of the boom to be deposited.

Which is better boom or Boomless sprayer?

boom sprayer advantages Boom sprayers are typically closer to the ground than a boomless sprayer, resulting in them being less affected by the wind, reducing the chance of chemical drift. Boom sprayers are generally used for spraying large areas, such as fields and pastures.

Why is it called a boom sprayer?

What is Boom Spraying? A Boom Sprayer usually has multiple spray nozzles (tips are usually the American terminology) spread out along arms (booms), pointed directly down.

How do you make a paint sprayer?

What is a dry boom sprayer?

A dry boom is effectively a sprayer boom that is fed only by hoses, and does not include any liquid filled boom pipe. Conversely, a boom that is fed by pipe/tube is generally referred to as a “wet boom”.

What is a boom sprayer?

A boom sprayer is the most common type of apparatus for applying herbicides in broadscale farming. A sprayer has many components, the most important being the nozzles, which split the herbicide into many small droplets that are projected through the air to the target.

How do you make a spray bottle out of a plastic bottle?

Make sure the spray cap is unscrewed from the bottle. Then, slice the plastic in a circle about 2 cm (0.79 in) away from the mouth to remove it from the bottle. You don’t have to cut around the mouth in a perfect circle — just try to make the width roughly the same all the way around.