A knapsack is small bag meant to carry items such as clothes, books, shoes or any other small items. It is also called a diaper bag. The most noticeable characteristic of a knapsack is its small size. As you look for a bag, it is advisable that you carry a smaller knapsack with you than a larger one.

What is a knapsack sprayer used for? A knapsack is a type of sprayer that disperses liquid through a hand-held nozzle that is attached to a pressurised reservoir carried on the operators back. Knapsack sprayers can be used to apply liquids such as fertilisers, herbicides and fungicides for example and is suited to spot treating areas.

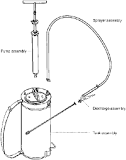

What are the parts of knapsack sprayer? It consists of a piston type pump, a platform with fork, a lever to operate the pump, pressure chamber, suction hose with strainer, delivery hose, and a spray gun with flow control knob and nozzle.

What is the size of a knapsack sprayer?

| Automation Grade | Manual |

|---|---|

| Power Source | Battery |

| Usage/Application | Agriculture |

| Tank Capacity | 18 Litre |

| Size/Dimension | 480 x 190 x 590 mm |

How many Litres is a knapsack sprayer? Knapsack sprayer consists of a pump and an air chamber permanently installed in a 9 to 22.5 liters tank.

Why is it called knapsack? It comes from the German knappen, “to bite,” and some experts believe that the name evolved from the fact that soldiers carried food in their knapsacks.

What does a knapsack look like? – Related Questions

What are the disadvantages of sprayer?

Disadvantages :1. Low efficiency and large labor intensity are not suitable for large-scale operation. 2. The liquid has run, run, run, leak and drip phenomenon.

What is the working principle of sprayer?

The sprayer works on Bernoulli’s theorem. Archimedes’s principle – the buoyant force applied by the fluid is equal to the weight of the displaced fluid.

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What are the types of sprayer?

These sprayers come in different types, namely, tractor-mounted, trailer-mounted, and truck-mounted. Depending on the vehicle you have and the size of the area you need to spray, you need to select a low-pressure sprayer that can fit enough gallons to finish the job.

What is the tank capacity of a manually operated knapsack sprayer in Litres?

Knapsack sprayer consists of a pump and an air chamber permanently installed in a 9 to 22.5 liters tank.

What is high volume sprayer?

All types of high volume sprayers have some kind of pump to supply pressurised spray liquid to the hydraulic nozzle which breaks the liquid into spray droplets and throws the spray away from it. The high volume sprayers are both manually operated or power operated type.

How do you calculate spraying rate?

Multiply the length of the area you plan to spray times the width. If you are using metres, then divide the product by 10,000, which is the number of m2 in a hectare (ha). For feet and acres, divide by 43,560 which is the number of ft2 in an acre (ac):

How do you maintain a knapsack sprayer?

- Never leave spray mixture in the machine. …

- Clean the sprayer. …

- Check the piping: check all the piping and fittings; replace faulty or worn parts (nozzles, anti-drip systems, etc.).

- Clean the nozzles and filters: Clean and rinse the clogged nozzles or filters using a brush and water.

Where is knapsack problem used?

The problem can be found real-world scenarios like resource allocation in financial constraints or even in selecting investments and portfolios. It also can be found in fields such as applied mathematics, complexity theory, cryptography, combinatorics and computer science.

What is knapsack problem with example?

The 0/1 knapsack problem means that the items are either completely or no items are filled in a knapsack. For example, we have two items having weights 2kg and 3kg, respectively. If we pick the 2kg item then we cannot pick 1kg item from the 2kg item (item is not divisible); we have to pick the 2kg item completely.

What is the advantage of using power sprayer?

Electric power sprayers have fewer moving parts and often have simpler plumbing. This means less can go wrong, fewer parts to maintain in inventory, and easier maintenance. Greener image. Electric battery-powered sprayer motors give operators a greener image.

How does an electrostatic sprayer work?

Electrostatic sprayers work by charging the antimicrobial liquid as it passes through a nozzle. The positively charged antimicrobial droplets are attracted to negatively charged environmental surfaces allowing for improved coverage on hard, non-porous environmental surfaces.

What is agricultural wheel sprayer?

I have proposed a wheel driven sprayer, it is a portable device and no need of any fuel to operate, which is easy to move and sprays the pesticide by moving the wheel. Materials and Methods. Indian farmers use traditional method, there is large scope for development in agricultural sector.

What is hand sprayer?

Hand sprayer is a type of continuous sprayer with a relatively constant release rate. The operator maintains pressure in the tank by pumping air with a lever with one hand and controls the spray nozzle with the other hand.

What are the parts of a sprayer?

- Wand.

- Nozzle.

- Control Locks.

- Pressure-Release Valves.

- Pump Handle with Flow Control.

- Hose or Tube.

- Pump.

- Sprayer Tank.

What is spray volume?

The correct volume of spray is the sprayer application rate multiplied by the number of acres. Example. You want to spray a 12-acre field and your sprayer applies 20 gallons per acre. Gallons of spray mixture = application rate (gallons per acre) × area to spray (acres) Therefore, put (20 × 12 =)

Which of the sprayer is mostly used by farmer?

Tractor-mounted sprayers are the most used, easy controls and well-engineered nozzles arrangements that carry out accurate Spraying of chemicals on the crops.

What are the types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What are different types of manual operated sprayers?

Manually operated hydraulic sprayers viz. Knapsack sprayers, twin knapsack sprayers, foot sprayers, hand compression sprayers; air carrier sprayers such as motorized knapsack mist blower cum duster (LV) and centrifugal rotary disc type sprayers are specially suitable for spray applications in crops.

What are the two types of sprayer?

Two general types of sprayers are available for greenhouse application of pesticides: hydraulic and low-volume. There are many variations of these that fit particular crops or growing methods.

What is hand compression sprayer?

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig.

What is the difference between sprayer and duster?

Sprayers are used to manage pests by using natural materials such as contaminations and small creatures in sprayers. A duster insecticide is a helpful tool for getting pesticides deep into cracks, crannies, and other similar spaces to kill crawling and flying insects, such as scorpions, bees, and other pests.

How do you use a backpack sprayer?

What are the types of sprayer?

These sprayers come in different types, namely, tractor-mounted, trailer-mounted, and truck-mounted. Depending on the vehicle you have and the size of the area you need to spray, you need to select a low-pressure sprayer that can fit enough gallons to finish the job.

What are the precautions to be taken when using knapsack sprayer?

Knapsack sprayer should be used to spray weedicides, flood jet or flat fan nozzle should be used while spraying. Wash and clean the sprayer with soap or detergent powder after spraying is completed. Follow the instructions written on the tin. Take bath and wash your cloths after spraying.