The types which are commonly used for ground application of agricultural chemicals are flat-fan, even flat-fan, and cone nozzle. Regular flat-fan nozzles are used for most broadcast spraying of herbicides and for certain insecticides when foliar penetration and coverage are not required.

What are different types of nozzles used in agriculture sprayers? Nozzle types commonly used in low-pressure agricultural sprayers include flat-fan, flood, raindrop, hollow-cone, full-cone, and others. Special features, or subtypes such as “extended range,” are available for some nozzle types.

How do I choose a nozzle for my sprayer? You’ll want to determine the nozzle flow rate at gallons per minute (gpm). To find that, start with your application rate in gallons per acre (gpa). Next, find an efficient and safe ground speed in miles per hour (mph). Then, determine the spray width per nozzle (W).

What do the numbers on spray nozzles mean? Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What are two common nozzles used in agricultural applications? – Related Questions

How do I choose a nozzle size?

The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

How high should a sprayer boom be off the ground?

This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

How many types of nozzle are there?

| Flat spray nozzles | Swirl nozzles | Impact nozzles |

|---|---|---|

| … = standard XR = large pressure range DG = anti drift AI = air injection (venturi) UB = side nozzle OC = eccentric nozzle | FL = full conical nozzle TXA = hollow conical nozzle TXB = hollow conical nozzle | TF = precision impact nozzle |

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

What is a 311 spray tip used for?

6 inch spray pattern ideal for narrow surfaces such as fences, decks and furniture. The . 011 inch hole size optimal for spraying thinner materials like semi transparent stains, water sealers, stains or polyurethanes.

How many gallons does it take to spray an acre?

Answer: On average, 1 gallon of mixed solution will cover about 1000 sq/ft, so it would take you about 44 gallons to cover an entire acre.

What’s the difference between a 515 and a 517 spray tip?

For example, a 515 tip will spray a 10-inch-wide fan and have a 15-thousandths of an inch orifice. It’s the combination of fan-width and orifice-size that determines how thick of a coating you’ll spray. Case in point – a 317 tip and a 517 tip both have the same orifice size – 17-thousandths of an inch.

What are the 2 types of nozzles?

The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

Which is the mostly used nozzle?

Round Nozzle It is the most used nozzle by the bakers around the world.

Do nozzles increase pressure?

In a convergent nozzle, there is an increase in velocity and a decrease in pressure, but we know that pressure is inversely proportional to area.

What are different types of sprayers?

- Knapsack Sprayer.

- Portable Power Sprayer.

- Knapsack Power Sprayer.

- Mist Dust Sprayer.

- HTP Sprayers.

- Orchard Sprayers.

Are DiamondBack nozzles worth it?

The DiamondBack Nozzle delivers precision prints, prints any filament, and offers a much longer nozzle life. In addition, the DiamondBack is easier to clean, reduces tip clogging, improves layer adhesion, lowers operating temperature, and delivers unmatched wear resistance.

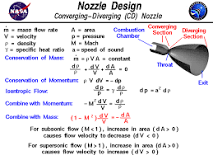

How do you design a nozzle?

A nozzle is a relatively simple device, just a specially shaped tube through which hot gases flow. Rockets typically use a fixed convergent section followed by a fixed divergent section for the design of the nozzle. This nozzle configuration is called a convergent-divergent, or CD, nozzle.

How thick can you print with a 0.4 nozzle?

So for a 0.4mm nozzle, you’ll be looking to print at 0.2mm layer height, or up to 0.3mm.

Which type of nozzle should be used for the spraying of pesticides?

Fan Nozzles The most common type of nozzle used in agriculture is the fan nozzle. A fan nozzle is widely used for spraying pesticides — both banding (over and between rows) and broadcast applications. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2).

How will you select a nozzle for a particular type of job?

- Select the application rate in gallons per acre (gpa). …

- Select a practical and safe ground speed in miles per hour (mph).

- Determine the spray width per nozzle (W).

- Determine the flow rate (gpm) required from each nozzle by using the following equation:

What is high volume sprayer?

All types of high volume sprayers have some kind of pump to supply pressurised spray liquid to the hydraulic nozzle which breaks the liquid into spray droplets and throws the spray away from it. The high volume sprayers are both manually operated or power operated type.

How do you use a nozzle chart?

On a standard nozzle chart, the top column that runs left to right is the pressure that you want to obtain. The left column top to bottom is the nozzle orifice size designation. The top to bottom column next to the orifice size column indicates the actual orifice measurement.

What are the different types of piping nozzles?

- Round Nozzle. The round nozzle has a plain round opening. …

- Star Shaped Nozzle. The star-shaped nozzle also has two types; open and close. …

- Basketweave Nozzle. …

- Drop Flower Nozzle. …

- Multi Opening or Grass Nozzle. …

- Leaf Nozzle. …

- Petal Nozzle. …

- Special Nozzle.

How many types of nozzles are there?

| Flat spray nozzles | Swirl nozzles | Impact nozzles |

|---|---|---|

| … = standard XR = large pressure range DG = anti drift AI = air injection (venturi) UB = side nozzle OC = eccentric nozzle | FL = full conical nozzle TXA = hollow conical nozzle TXB = hollow conical nozzle | TF = precision impact nozzle |

What are the 2 types of nozzles?

The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

What are the different types of fire nozzles?

- Smooth or solid bore.

- Fixed orifice or single gallonage (sometimes called variable pressure/variable flow)

- Selectable or adjustable gallonage.

- Automatic or constant pressure.

- Multi-purpose nozzle (combination smooth bore and fog)