Spray paint offers more even coverage without brush strokes. Spray primer is a million times faster than brush primer. Spray paint is a million times faster than brush on paint. Spray paint is typically oil based, therefore more durable than water based spray or regular latex paint.

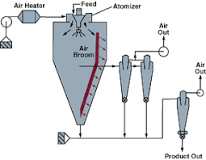

How many types of spray dryers are there? … Among them are the rotary, nozzle, two-fluid, pressure and ultrasonic nozzle (Walzel, 2011). Atomization is a crucial part of the spray dryer because it influences the drying rate, particle diameter, particle distribution, and dispersibility of the powder for rehydration (Chegini & Taheri, 2013) .

What is spray drying equipment?

What is custom spray drying? Custom spray drying – transform liquids into dry powders by spraying the liquid into a spray dryer where it makes contact with hot air that removes the moisture.

What is the mechanism of spray dryer? A spray dryer takes a liquid stream and separates the solute or suspension as a solid and the solvent into a vapor. The solid is usually collected in a drum or cyclone. The liquid input stream is sprayed through a nozzle into a hot vapor stream and vaporized. Solids form as moisture quickly leaves the droplets.

What temperature is spray drying? The typical spray drying process used today employs air heated up to 400° Fahrenheit to dry an atomized liquid into a powder.

What are the advantages of spray? – Related Questions

Who invented spray dryer?

Its first observation is dated 1860 and a primitive spray dryer device was patented by Samuel Percy in United States in 1872 [1, 2, 3]. Ever since it was first discovered, the spray-drying technique has been improved concerning its operational design and applications.

What is spray drying in industry?

Spray drying is the process of creating a dry powder out of a liquid or slurry through rapid drying with a hot gas. For many thermally-sensitive materials such as those used in the food and pharmaceutical industries, this is the preferred drying method. Spray dryers can dry very quickly compared to other methods.

What are the components of spray dryer?

- feed pump.

- atomizer or spray nozzles.

- air heater, air disperser.

- drying chamber.

- powder recovery systems.

- process control systems.

- Click here to learn the specifications of PacMoore’s spray dryers.

How long does spray drying take?

3.2 Spray Drying Drying is accomplished within a few seconds. The dried product is removed from the bottom of the tower, and the waste gas stream exhausted through a cyclonic dust separator.

What are the advantages of spray dryer?

Benefits of Spray-Drying Some of the advantages of spray-drying include its ability to be fully automated and continuous. Short residence times and suitability for both heat-sensitive and heat-resistant foods are other advantages. The technology is suitable for a variety of feed materials, provided they are pumpable.

What is the difference between spray drying and freeze drying?

Product temperatures in freeze drying are generally below 0°C in primary drying and 20-30°C during secondary drying, whereas product temperatures in spray drying are regularly above 80°C.

What is spray dryer PDF?

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.

How can you increase the efficiency of spray drying?

Spray drying energy efficiency can be improved by widening the gap between inlet and outlet temperatures and adding heat recovery equipment. For many years, spray drying has been one of the most energy-consuming drying processes, yet it remains one that is essential to the production of dairy and food product powders.

Which product is not tried by spray dryer?

| Q. | Which product is NOT dried by spray dryer? |

|---|---|

| B. | Fruit Juice |

| C. | Lactose |

| D. | Bacterial & viral cultures |

| Answer» d. Bacterial & viral cultures |

What is the size range of particle produced from spray drying?

The droplets lose moisture rapidly and dry when they meet a stream of hot gas. The drying occurs in an insulated chamber. Powders produced have relatively uniform characteristics and are collected from the spray dryer. Spray drying usually provides particles with a mean particle size below 10 μm, preferably 5 μm.

What is cyclone in spray dryer?

Cyclone separators are used in the dairy industry for • gas–solids separation, mainly for separating product fines from the air leaving spray dryers and fluidized bed dryers, both to increase yield and to minimize air pollution. This is the commonest application of cyclones.

What is spray drying in food preservation?

Spray drying is the process where a mixture of compounds is made in its liquid or slurry form that is finally converted into dry powder form. This drying technique emerged way back in 1860s and was used during World War II. It helped to make easy shipment of larger quantities of food within limited storage area.

What types of dryers are there?

- Standard vented dryers. A heating element raises the temperature of the air in the dryer and the moisture from the wet clothes is vented through aluminum ducts. …

- Ventless dryers. …

- Condenser dryers. …

- Heat pump dryers.

What is the principle of FBD?

Fluid bed dryers work on the principle of fluidization, a process where a material is converted from a static solid-like state to a dynamic fluid-like state. In this process, hot gas or air is introduced through a perforated distribution plate into the area holding the material.

What is drying method?

Drying is the process of using evaporation to remove water from a solution, suspension, or other solid-liquid mixture. In addition to solids, the process can also be used to remove water from liquids or gases.

How do you increase particle size in spray drying?

By operating the spray dryer at very low inlet temperatures and/or low outlet humidity, we can increase the number of hollow particles from 32% to 59% for a 75:25 (WP:MD) powder, simultaneously reducing the number of wrinkled particles from 34% to 19%.

What is a fluid bed dryer?

Fluid or Fluidised bed dryer is a kind of equipment used extensively in the pharmaceutical industries to reduce the moisture content in raw ingredients like powder and granules. The working principle of this equipment includes fluidization of the fed materials.

Why maltodextrin is used in spray drying?

Spray drying technique is also appropriate for heat sensitive components. Maltodextrin, gum arabic and gelatin are successfully used as drying aids to facilitate drying. Maltodextrin is one of the common drying aids for spray drying owing to its beneficial role as a carrier or an encapsulating agent.

What types of dryers are there?

- Standard vented dryers. A heating element raises the temperature of the air in the dryer and the moisture from the wet clothes is vented through aluminum ducts. …

- Ventless dryers. …

- Condenser dryers. …

- Heat pump dryers.

What are the components of spray dryer?

- feed pump.

- atomizer or spray nozzles.

- air heater, air disperser.

- drying chamber.

- powder recovery systems.

- process control systems.

- Click here to learn the specifications of PacMoore’s spray dryers.

What is spray drying in pharmaceutical industry?

Spray drying is a drying technique used in the pharmaceutical industry to produce dry or coarse powder from liquid or slurry. It is usually used in the production of active pharmaceutical ingredients (APIs), the active ingredients in drugs.

What is spray dryer PDF?

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized.