Shotcrete has all of the advantages of standard concrete materials, such as its high tensile strength, durability, fire retardation, low permeability, and thermal efficiency.

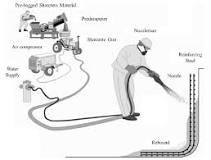

What is a shotcrete machine? Shotcrete equipment allows for the projection of a concrete mixture at high pressure. Shotcrete equipment includes a mixer, an additive pump, compressor, sprayer arm and control system, and is usually found on a motorized chassis. This equipment is used in trenchless installation.

What is the difference between shotcrete and concrete? Shotcrete is pretty much the same thing as concrete (i.e. it is used ready mixed), but its name derives from the way it is applied. Instead of being poured, it is fired out of a hose at high speed (you can see how it gets its name!).

How thick can shotcrete be applied? There is no stated maximum thickness for shotcrete used in shear walls or any other type of wall. Walls have been successfully placed to a thickness of 36 in. (914 mm) for some time. The two main concerns are the heat of hydration and proper encapsulation of the reinforcing steel.

How do you use shotcrete? Shotcrete is applied using a wet- or dry-mix process. The wet-mix shotcrete process mixes all ingredients, including water, before introduction into the delivery hose. The dry-mix shotcrete process adds water to the mix at the nozzle.

Is shotcrete stronger than concrete? Shotcrete takes less time than pouring concrete, and it forms a strong and consistent coating. It also is an inexpensive way to apply concrete in curves and irregular shapes, which are often difficult to impossible to achieve with convention concrete methods.

What are the advantages of shotcrete? – Related Questions

Can I do shotcrete myself?

DIY shotcrete is achievable for a hobbyist, owner/builder or a contractor. It is all about the speed of delivery you want to accomplish. The best advice ever shared with me about shotcrete and pumping concrete is to choose the equipment needed as a package, because each set up works best at a specific scale.

Why is shotcrete used?

Because it can take any shape, is easily coloured, and can be sculptured after application, shotcrete is used for a variety of fancy concrete structures, including artificial rock walls, zoo enclosures, canopy roofs, refractory linings, pools, and dams.

How long does it take for shotcrete to dry?

Concrete, when applied using the shotcrete process, or cast-in-place, needs to cure for 7 days. Water is the best curing method (7 continuous days).

How do you mix shotcrete?

Shotcrete typically consists of one part cement and four parts sand by weight with approximately 7% water by mass of dry ingredients.

Can you shotcrete in the rain?

Shotcrete needs to be protected from rain until it obtains its final set, usually 4 or 5 hours. Following final set, it should be wet cured for at least 4 days, preferably 7 days if possible. The exposure to rain would prove beneficial as the rain would assure the presence of moisture for continued curing.

What is better shotcrete or gunite?

Gunite generally lasts longer and maintains a higher quality than shotcrete. For instance, gunite tends to dry faster than shotcrete, leading to a much smoother surface and avoiding significant cracks from shrinking. Gunite can also withstand up to 9500 psi, a much higher psi than shotcrete.

How thick are shotcrete pool walls?

Generally, the pool walls need to be between three and four inches thick. Smooth the pool walls with your trowel, as you did for the base. Now the concrete has to cure properly before you can fill it with water. The concrete curing process allows the concrete to reach maximum strength and takes approximately 28 days.

Why is there a shortage of shotcrete?

With various other industries, the Covid-19 outbreak has caused a negative impact on the shotcrete market as well. This is mainly due to the cancellation of major projects, unavailability of raw materials, shortage of laborers, and most importantly, unpredicted postponement of construction projects.

Can shotcrete be applied by hand?

Shotcrete is concrete placed at high velocity to achieve compaction. It is dependent on the projection of material with air velocity of 60 to 80 mph (97 to 129 km/h) from the nozzle to consolidate the concrete material in place. It cannot be hand-applied.

Is shotcrete a watertight?

The result is a continuous waterproofing barrier, fully bonded with the shotcrete, that can withstand up to 200 ft. of hydrostatic pressure.

Why do gunite pools crack?

A common cause with pool cracks is from too-thin gunite used during the installation process. During the construction process, the gunite might not adhere properly to the steel framework. When this occurs, the gunite “rebounds,” or bounces back after application. Rebound gunite should be removed and thrown away.

What is a shotcrete wall?

A shotcrete wall is constructed by using a special mix of high-strength concrete, which is sprayed at high velocity on the wall using compressed air, to form a retaining structure, drain, or wall. shotcrete walls provide a permanent and cost-effective solution for retaining wall construction.

What type of concrete is used in pools?

Concrete pools can be made of either shotcrete or gunite. The difference is when the concrete mixes with the water. Shotcrete refers to wet concrete that’s already fully mixed before it’s shot out of a hose.

What is difference between Guniting and shotcrete?

The biggest difference between the two materials is when water is introduced to the mix. With gunite, the water is added on site. With shotcrete, the water is added prior to arrival. These two mixing techniques each have their own advantages.

Do it yourself spray on concrete?

Can you spray concrete?

Sprayed concrete is the method by which concrete is sprayed into place, rather than the more conventionally used pouring or placing into formwork. According to the Sprayed Concrete Association other terms used include Gunite, Shot Concrete and Shotcrete. There are many applications and uses for sprayed concrete.

What are the 4 types of concrete?

- Reinforced Concrete.

- Lightweight Concrete.

- High-Strength Concrete.

- High-Performance Concrete.

- Precast Concrete.

What are the types of shotcrete?

There are two types of Shotcrete Technology. Which is as follows. Dry-Mix Shotcrete. Wet-Mix Shotcrete.

What are the two types of process in shotcrete?

The two types of shotcrete processes, dry shotcrete (also known as gunite), and wet shotcrete, have grown steadily in popularity in both concrete repair and new construction. This article will compare and contrast the two shotcrete processes.

Is it normal for shotcrete to crack?

Although it is a rare occurrence, shotcrete pools can crack. While usually happening within the first year, cracks can be due to shrinkage, settlement, improper engineering and design, or poor technique.

What happens if you dont water shotcrete?

Lack of curing and exposure to windy, hot, or dry conditions will certainly increase the potential for shrinkage and cracking of the concrete. Lack of curing will prevent the concrete from achieving its maximum potential strength.

Why do you water shotcrete?

Shotcrete / concrete is ready for water as soon as the initial set is complete, which is about 4-6 hrs after placement. Water is applied to aid in hydration/curing, a process which decays exponentially, so watering is most critical in the first hours/days after placement.

Which grade of concrete is used in shotcrete?

The Indian standard suggests that sand for shotcrete shall grade evenly from fine to coarse as per Zone II and Zone III grading of IS 383-1970 [7]. The fine aggregate grading limits specified by IS 9012 and ACI 506R are in similar lines.

How do you calculate shotcrete quantity?

Multiply the total square feet times the thickness of the floors and walls. For example, if your walls are 300 feet square and 8 inches thick ( 8 inches converted to feet is . 75), multiply 300 times . 75, and you have the total cubic feet of concrete to be poured.

What is the strongest cement mixture?

C40 concrete is the strongest and most durable mix and for good reason townhomes for sale san diego. It can handle almost any abuse, including withstanding corrosion, making it ideal for farm-based and laboratory environments.

Why is there a shortage of shotcrete?

With various other industries, the Covid-19 outbreak has caused a negative impact on the shotcrete market as well. This is mainly due to the cancellation of major projects, unavailability of raw materials, shortage of laborers, and most importantly, unpredicted postponement of construction projects.

What is shotcrete and what are the two methods of shotcreting?

The two basic methods for applying shotcrete are the dry-mix process and the wet-mix process. The term gunite is frequently used when referring to the dry-mix method; other terms such as air-placed concrete, gunned concrete and sprayed concrete have also been used in the past to describe the process.

What is difference between Guniting and shotcrete?

The biggest difference between the two materials is when water is introduced to the mix. With gunite, the water is added on site. With shotcrete, the water is added prior to arrival. These two mixing techniques each have their own advantages.