- HANDLES A WIDE VARIETY OF FLUIDS WITH HIGH SOLIDS CONTENT: …

- SELF PRIMING. …

- ABILITY TO RUN DRY. …

- EXPLOSION PROOF. …

- PUMPING EFFICIENCY REMAINS CONSTANT. …

- VARIABLE FLOW RATE AND DISCHARGE PRESSURE. …

- CAN NOT OVERHEAT. …

- NO MECHANICAL SEALS, COUPLINGS, OR MOTORS.

Does ECHO make a backpack sprayer? Style Choice. ECHO Sprayers are available in lightweight, easy-to-carry handheld models or durable backpack models with professional-grade shoulder straps and waist belts – the style choice is yours.

What is the difference between a piston and diaphragm sprayer?

How do you put the straps on a backpack sprayer?

How do you use a backpack pump sprayer?

Does ECHO make a fogger? ECHO’s full lineup of duster / mist blowers. ECHO dusters and mist blowers feature three different nozzle types; brass adjustable, fixed cone and fixed fan. 4-stage heavy duty air filters ensure the engine always runs smoothly and is free from dust and debris and fold-away handles make storing your power tool a breeze.

What are the advantages of a diaphragm pump? – Related Questions

How far can a backpack sprayer spray?

How far can a backpack sprayer spray? This depends on the pack, but most can handle between 10 and 30 feet, with an average of 20 feet.

What is a diaphragm sprayer pump?

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of a housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

How do you attach a shoulder strap to a Greenwood backpack sprayer?

How does the backpack pressure sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How do you prime a backpack sprayer?

How do you calibrate a pump sprayer?

- Mark off a plot 18.5 feet by 18.5 feet.

- Fill the sprayer to normal capacity with water.

- Pump the sprayer to the pressure normally used to apply herbicides.

- Spray water over the plot area while maintaining normal and constant operating pressure.

- Record the time in seconds it takes to spray the plot area.

Can a Stihl sprayer be used as a blower?

Stihl sprayers are easy to use, easy to fill, and feature intuitive controls for precise application. These sprayers provide excellent spraying coverage and can also be used as a powerful leaf blower for easy cleanup.

How do you make a mosquito fogger?

Put a 1/4-pound of garlic in a blender with one quart of water and blend until it is a smooth liquid consistency. Place a piece of cheesecloth over the top of a mason jar and slowly pour the mixture through it to strain out the bits of garlic. Pour the garlic juice into the fogger tank and use immediately.

How many square feet will a 4 gallon sprayer cover?

Divide (4) gallons by (64) GPA 4/64=. 0625 Which means your sprayer can spray . 0625 or 2723 square feet with one tank full.

How long does it take to spray 1000 square feet?

143′ length x 7′ width = 1,000 square feet covered by your technicians every 30 seconds. However, keep in mind that all turf gets sprayed twice. That means you are achieving an effective coverage of 1,000 square feet every 60 seconds.

How many square feet will a backpack sprayer cover?

A backpack sprayer can typically cover between 1000 and 10,000 square feet. The total area it can cover depends on the application rate of the product being sprayed as well as the volume of the sprayer tank.

How does a diaphragm sprayer work?

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

How does a diaphragm airless paint sprayer work?

Diaphragm pumps In a diaphragm pump, a rod powered by a motor operates diaphragms that expand and contract, taking in fluid through the inlet valve and expelling it out of the gun.

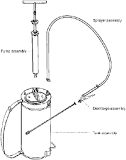

How does a compression sprayer work?

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig. 9.4).

What are the disadvantages of a diaphragm pump?

| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

How does a diaphragm sprayer work?

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.