What is the best air pressure for spray painting? Again, it’s essential you check your specific model’s recommendations, but your HVLP spray gun PSI will likely sit between 25-30 PSI for something like using an air compressor for spraying cars, rising to 40 PSI in some cases where higher atomisation is needed.

How much pressure is in a pump sprayer? The hand held sprayer has a plastic compression pump that is sealed with rubber O-rings. The compression pump is hand actuated to an operating pressure of 40 PSI.

How many PSI is a boom sprayer? Generally, the operating pressure for a typical boom-sprayer ranges from 15 to 80 psi. Most nozzles tend to produce a greater volume of spray in finer droplets at higher operating pressures.

How far will a pump sprayer spray? The range of a pump sprayer depends on the spray pattern. It will spray the farthest when set to a narrow stream. Most pump sprayers can spray up to 20 feet, and some more powerful sprayers are capable of reaching 30 feet.

What are the four components of a high pressure spray system?

- Airhead.

- Flow regulator.

- Nozzle or peak.

- Tank (depending on its type the gun can have a deposit or be connected to a tank)

How far can a pressure sprayer reach? Reach up to 40-60 feet away with this nozzle. Great for cleaning the sides of buildings or homes without ladders, scaffoldings or telescoping wands.

How much air does a spray gun need? – Related Questions

How do you pressurize a sprayer?

What pressure should a sprayer run at?

The normal recommended operating pressure for regular flat-fan nozzles is 20 to 30 psi. At these pressures, this nozzle type will produce medium to coarse drops that are not as susceptible to drift as the finer drops produced at pressures of 40 psi or greater.

What pressure should a sprayer be?

Running from 40-80 PSI usually. As crw said, the controller will try to match the pump to your ground speed by changing the speed of the pump. That will of course affect the pressure at the nozzles. Lower pressures should mean courser droplets, high pressure = finer droplets.

What pressure should sprayer be set at?

Depending on the type of spray tip installed, a pressure range (at the spray tip) of 10 to 30 pounds per square inch (psi) is usually appropriate for herbicides, while a range of 30 to 50 psi is most often appropriate for insec- ticides and fungicides.

Which is the best spray pump?

- Petrol Portable STIHL Power Sprayer SG 230.

- IBell Power Sprayer.

- Fortune Power Sprayer.

- Kisankraft Power Sprayer.

- Neptune Knapsack Farming Power Sprayer.

- E-AgroCare Knapsack Sprayer.

- Fujiaka Power Sprayer.

- BKR Honda Four Stroke Power Sprayer.

How do you spray tall trees with pesticides?

- Adjust the settings on the sprayer for the size of your tree. …

- Mix the insecticide in a bucket according to the package instructions. …

- Squeeze the trigger on the sprayer to activate the spray. …

- Dispose of any spray left over at the end of the day.

Which type of sprayer is used for tall trees?

A high-pressure system is necessary to spray heights from 50 to 100 feet. Options are a hydraulic sprayer or an air-blast sprayer. A hydraulic sprayer uses water to force a chemical treatment to the height needed, and an air-blast sprayer uses a combination of water and air for that task.

What are two types of spray guns?

- Airless Paint Sprayer. Airless sprayers work by pumping out paint at a very high pressure, fanning out droplets to evenly coat the surface. …

- Pneumatic Air Sprayer. …

- HVLP Sprayers. …

- Paint Sprayer Accessories.

How do agricultural sprayers work?

Sprayers are designed as full spraying systems with a pump and plumbing components to pressurize and drive the spray fluid from a tank and deliver to the spray nozzle(s) a consistent pressure stream optimized for the target application.

What is the most important part of the sprayer?

A pressure regulator is one of the most important parts of a sprayer. It controls the pressure and therefore the quantity of spray material delivered by the nozzles. It protects pump seals, hoses, and other sprayer parts from damage due to excessive pressure, and it bypasses excess spray material back to the tank.

Is a turbo nozzle worth it?

Turbo nozzles have been one of the most important accessories developed. These efficient tools provide the power of a zero-degree pattern. The circular motion also adds extra agitation to cleaning tough jobs like caked-on mud. They are designed to provide a 200% cleaning efficiency over a 25-degree flat fan nozzle.

How do you make a high pressure water nozzle?

What is the most powerful pressure washer nozzle?

Red Spray Tip (0-Degrees) The red spray tip creates a 0-degree spray pattern and is the most powerful nozzle of them all.

What is a pressurized sprayer?

A pressure sprayer is a chamber which is filled with a liquid which can be a lubricant, paint or chemical, then filled with compressed air to allow the liquid to be sprayed at pressure.

Why is my sprayer not building pressure?

If you are experiencing low pressure output from your sprayer and have ruled out any other parts as the cause, the impeller coupling may have lost its seal, or the impeller itself may be damaged, clogged or broken. In some cases, the pump may be disassembled and cleaned to fix the problem.

Why is my pump sprayer not spraying?

How high should a sprayer boom be off the ground?

This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

What is the effect of decreasing the operating pressure of a spray unit?

Reducing hydraulic pressure reduces nozzle flow rate, increases median droplet size, and typically reduces spray fan angle. Increasing pressure increases nozzle flow rate, reduces median droplet size and typically increases spray fan angle.

What PSI should I use to spray primer?

You want to set it with the trigger pulled. To begin, set it at 50 psi. Close the air volume control knob (usually located beside where the air hose enters the gun) and with the trigger pulled, open it to the point where the air volume starts to stay the same, and then stop.

How much pressure does a HVLP gun need?

HVLP, or High-Volume/Low Pressure, uses a high volume of air (typically between 15-26 CFM) delivered at low pressure (10 PSI or less at the air cap) to atomize paint into a soft, low-velocity pattern of particles. In most cases, less than 10 psi is needed in order to atomize.

Do you need a regulator on spray gun?

It’s a good idea to have a regulator on or close to the gun, to mitigate any pressure drops in your system across air lines, and to be able to tune your gun’s spray pattern based on the type and viscosity of material you’re shooting.

What do the numbers on a sprayer nozzle mean?

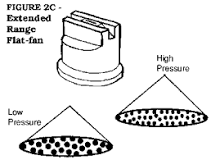

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

What are different types of nozzles used in agriculture sprayers?

Nozzle Description. Nozzle types commonly used in low-pressure agricultural sprayers include flat-fan, flood, raindrop, hollow-cone, full-cone, and others. Special features, or subtypes such as “extended range,” are available for some nozzle types.

What pressure should a sprayer run at?

The normal recommended operating pressure for regular flat-fan nozzles is 20 to 30 psi. At these pressures, this nozzle type will produce medium to coarse drops that are not as susceptible to drift as the finer drops produced at pressures of 40 psi or greater.

What pressure should sprayer be set at?

Depending on the type of spray tip installed, a pressure range (at the spray tip) of 10 to 30 pounds per square inch (psi) is usually appropriate for herbicides, while a range of 30 to 50 psi is most often appropriate for insec- ticides and fungicides.

What is a pressure sprayer?

What is a pressure sprayer? A pressure sprayer is a chamber which is filled with a liquid which can be a lubricant, paint or chemical, then filled with compressed air to allow the liquid to be sprayed at pressure. Units are typically of cast iron or stainless steel design.

How does a pump sprayer work?

The pump forces this liquid down a narrow barrel and out a small hole at the spray valve. Inside the shroud, there is a small spring which compresses the fluid once pulled back by the trigger. The moving piston compresses the spring, so when you release the trigger, the piston is pushed back out of the gasket.