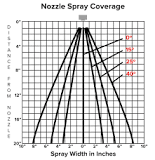

This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

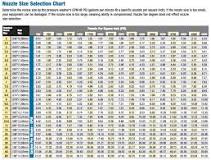

How do I choose a spray nozzle? The best method for choosing the correct nozzle tip size is to determine the gallons per minute (GPM) of nozzle output required and then select a nozzle tip size that, when operated within the recommended pressure range, will provide this flow rate.

What are different types of nozzles used in agriculture sprayers? Nozzle Description. Nozzle types commonly used in low-pressure agricultural sprayers include flat-fan, flood, raindrop, hollow-cone, full-cone, and others. Special features, or subtypes such as “extended range,” are available for some nozzle types.

What are the different types of spray nozzles? There are 5 basic spray pattern types: flat fan, solid stream, full cone, hollow cone and mist/fog.

How do you spray with a boom sprayer?

How many nozzles does a boom sprayer have? Five nozzles can produce the required flow, each at different pressures.

How high should a sprayer boom be off the ground? – Related Questions

How do I choose a nozzle size?

The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

Which is the mostly used nozzle?

Round Nozzle It is the most used nozzle by the bakers around the world.

What do the numbers on spray nozzles mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

What are flat-fan nozzles used for?

Flat-fan (A): These are the most common nozzles used for turf applications and produce a fine to medium droplet. Spray coverage is excellent but drift may be a concern. Air-induction (B): These nozzles produce a medium to coarse droplet which shatters upon contact with the leaf blade to provide better coverage.

What are hollow cone nozzles used for?

The hollow cone spray pattern is ideal for cooling, washing, gas scrubbing / cooling, dust control and fire protection. Nozzle styles include threaded, flanged and quick-connect. Spray pattern variations include standard, extra-wide angle and wide angle.

Where would you use a boom sprayer?

A boom sprayer is the most common type of apparatus for applying herbicides in broadscale farming. A sprayer has many components, the most important being the nozzles, which split the herbicide into many small droplets that are projected through the air to the target.

How do you calculate gallons per acre for spraying?

GALLONS per acre formula Simply incorporate the output of a single nozzle in gallons per minute (GPM) and multiply by 5,940. Then divide by the product of miles per hour (MPH) times the distance between nozzles in inches (width) on the spray boom.

How is spray rate boom sprayer calculated?

Drive 136 feet and measure the time in seconds. If it took 15 seconds, catch the output from each of the three nozzles for 15 seconds. If each tip delivers 5 ounces, the total ounces collected per row is 15 ounces. This represents the sprayer application rate of 15 GPA.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

Which type of nozzle should be used for spraying pesticides?

Fan Nozzles The most common type of nozzle used in agriculture is the fan nozzle. A fan nozzle is widely used for spraying pesticides — both banding (over and between rows) and broadcast applications. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2).

How will you select a nozzle for a particular type of job?

- Select the application rate in gallons per acre (gpa). …

- Select a practical and safe ground speed in miles per hour (mph).

- Determine the spray width per nozzle (W).

- Determine the flow rate (gpm) required from each nozzle by using the following equation:

What does nozzle size mean?

The orifice size of the nozzle determines the operating pressure of your machine. As a rule of thumb, the smaller the orifice, the greater the restriction of water flowing through the machine. This causes the pressure to increase. Choosing a nozzle with too large of an orifice will reduce operating pressure.

Can you print 0.2 mm with a 0.4 mm nozzle?

So for a 0.4mm nozzle, you’ll be looking to print at 0.2mm layer height, or up to 0.3mm. Your minimum would want to be around 0.1mm, any lower than this and you’re just increasing your waiting time for not much benefit (on the same 0.4mm size nozzle).

How do you calculate flow rate of a nozzle?

- Any nozzle will produce certain flow rate at a given pressure differential. …

- The flow rate for a given nozzle can be calculate by the following formula.

- Q= Flow rate.

- K = K factor for nozzle.

- P = Pressure differential at the nozzle.

- n = Is a constant that depends upon the spray pattern type.

Do nozzles increase pressure?

In a convergent nozzle, there is an increase in velocity and a decrease in pressure, but we know that pressure is inversely proportional to area.

What are different types of sprayers?

- Knapsack Sprayer.

- Portable Power Sprayer.

- Knapsack Power Sprayer.

- Mist Dust Sprayer.

- HTP Sprayers.

- Orchard Sprayers.

What is a jet nozzle?

A jet nozzle is simply the portion of a jet engine that compresses the material going through it to increase thrust, which helps to propel the plane through the air. This is most often seen at the rear of a jet airplane engine.

How do you use a Russian nozzle?

How many different piping tips are there?

The number of piping tips found in sets usually ranges from 10 to 100 different kinds of styles. Piping tip sets are ideal for bakers who are looking to own a variety of tips to have several options while decorating desserts.

What is a drop nozzle?

Cone Tips | Nozzle Assemblies | Drop Nozzles. Like band spraying, Drop Nozzles can be used to apply pesticide directly in a band either over the row, at the base of the plant from between the row, or both. Unlike band spraying, thought, these drops are usually used for post emergent spraying.

How will you select a nozzle for a particular type of job?

- Select the application rate in gallons per acre (gpa). …

- Select a practical and safe ground speed in miles per hour (mph).

- Determine the spray width per nozzle (W).

- Determine the flow rate (gpm) required from each nozzle by using the following equation:

What do the numbers on a spray nozzle mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

How do you size a pressure washer nozzle?

There are a variety of sizes but the most commonly used are between 3.0 to 6.5, sized in . 5 increments. All nozzles are stamped with a 5 digit number which identifies both the fan degree and nozzle size. For example, a nozzle with the number 40055 has a 40 degree fan pattern and is 5.5 in size.

How do you calculate flow rate of a nozzle?

- Any nozzle will produce certain flow rate at a given pressure differential. …

- The flow rate for a given nozzle can be calculate by the following formula.

- Q= Flow rate.

- K = K factor for nozzle.

- P = Pressure differential at the nozzle.

- n = Is a constant that depends upon the spray pattern type.