How far can a backpack sprayer spray? This depends on the pack, but most can handle between 10 and 30 feet, with an average of 20 feet.

Are piston or diaphragm sprayers better? Piston – A piston pump is the better option when spraying anything at a distance, such as trees and bushes, because of its higher pressure. They are normally a little less expensive and easier to repair. However, they aren’t as durable as a diaphragm pump.

What is a piston pump sprayer? Piston sprayers include a cylinder housing in which, when pumping, a piston moves up and down to create pressure. Most piston models can reach up to 90 psi. Higher psi delivers smaller droplet size and has a further reach. Use with low abrasive, low viscosity spray liquids such as herbicides and insecticides.

What is difference between diaphragm and piston? Diaphragm-sensed regulators use a flexible element to adjust to these changes and to ensure constant outlet pressure and flow relative to depth; piston-sensed regulators use a sliding metallic piston that moves to adapt to these variations.

How do you pressurize a backpack sprayer?

How does a piston diaphragm pump work? Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

How far will a backpack sprayer spray? – Related Questions

What is an internal piston pump?

How does a backpack pump sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How does a pump sprayer work?

How does a compression sprayer work?

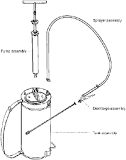

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig. 9.4).

How does a piston regulator work?

When the regulator is pressurized by opening in the tank, the piston moves and allows air to past the high pressure seat. When the pressure inside the regulator reaches IP, then it closes, and air stops flowing. When you take a breath, it moves and lets air through.

What is a piston flush valve?

How does a diaphragm airless paint sprayer work?

Diaphragm pumps In a diaphragm pump, a rod powered by a motor operates diaphragms that expand and contract, taking in fluid through the inlet valve and expelling it out of the gun.

Why is my sprayer not building pressure?

If you are experiencing low pressure output from your sprayer and have ruled out any other parts as the cause, the impeller coupling may have lost its seal, or the impeller itself may be damaged, clogged or broken. In some cases, the pump may be disassembled and cleaned to fix the problem.

How much pressure should a pump sprayer have?

Most hand pump sprayers are limited to about 40 psi.

How much pressure does a pump sprayer have?

The hand held sprayer has a plastic compression pump that is sealed with rubber O-rings. The compression pump is hand actuated to an operating pressure of 40 PSI.

What are the disadvantages of a diaphragm pump?

| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

Can you flow through a diaphragm pump?

WHAT KIND OF FLUID DOES A DIAPHRAGM PUMP TRANSFER? Diaphragm pumps will move nearly any kind of fluid. Some common examples of fluids pumped using a diaphragm pump are water, oil and acid. Diaphragm pumps are capable of pumping high viscosity fluids from adhesives and gear oils to hand lotions, surfactants and resins.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

How much does a full backpack sprayer weigh?

Backpack sprayer’s filled with spray solution weigh 30 to 40 pounds. A comfortable and convenient carrying system is important to ensure operator comfort, reducing fatigue which enhances application practices.

How do you use a nylex backpack sprayer?

Spray the desired area by holding down the handle on the trigger (F). The trigger can be locked for continual spraying. Unscrew and remove the hose (G). Ensure that pressure is released and that all sprayer components (including the bottle filter and cap) are rinsed thoroughly with water after use.

Why is my pump sprayer not spraying?

What are the types of sprayer?

- Knapsack Sprayer.

- Portable Power Sprayer.

- Knapsack Power Sprayer.

- Mist Dust Sprayer.

- HTP Sprayers.

- Orchard Sprayers.

How do you release pressure from a pump sprayer?

- Turn the tank upside down.

- Squeeze the flow control lever until all the air pressure is gone.

- If your sprayer has a pressure relief valve, turn knob clockwise until all air pressure is gone.

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What is the desirable quality of sprayer?

Desirable quality of a sprayer It should deliver the liquid at sufficient pressure so that the spray solution reaches all the foliage and spreads uniformly over the plant body. It should be light in weight yet sufficiently strong, easily workable and repairable.

What is the HP power required for power sprayer?

Needs 3 HP Engine or Electric Motor.

How does a diaphragm sprayer work?

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

How does a compression sprayer work?

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig. 9.4).