- A plasma spray gun acts as the source of the flame.

- Plasma gas is fed into the spray gun as the heating source.

- Plasma is created through an electric charge.

- A powder coating is fed externally through a powder supply.

- Plasma exits through a special anode nozzle to interact with the powder.

What is spray coating machine? One of the most commonly used surface finishing techniques is known as spray coating. It can be performed manually or automatically using a variety of machines. Manual spray coating has a number of drawbacks, including but not only very poor transfer efficiency, inconsistent coating quality and low productivity.

What is spray coating process? Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The “feedstock” (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame).

Which is a spray material? With cermet spray materials, consisting of hard ceramic particles and metallic binder, effort is generally made to retain the hard phase in the powder to deposit so that the compositions and microstructure of the composite deposit can be designed through powder design. WC–Co is a typical material of this kind.

What is thermal spray coatings? What is Thermal Spray Coating? Thermal spraying is an industrial coating process that consists of a heat source (flame or other) and a coating material in a powder or wire form which is literally melted into tiny droplets and sprayed onto surfaces at high velocity.

What is thermal spray material? Thermal spray is a process where metals, ceramic, cermet and selected polymeric materials are fed in the form of powder, wire and rods to a torch where the materials are heated or melted, and accelerated in the gas stream towards a substrate where they form a splat.

How does plasma spray work? – Related Questions

What is metal spraying process?

Metal Spraying is a process that has been used for over 100 years around the world, where molten metal or softened particles are applied to a prepared surface (substrate) to enhance its properties (hardness, anti-corrosion, wear, dielectric, restoring dimensions etc.).

What is spray weld?

Spray welding is a term used to classify several welding procedures in the form of thermal spraying. It is an industrial activity that involves atomizing and spraying a powder or wire onto a metal surface at a high velocity with compressed gas.

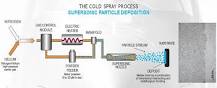

What is cold spray technology?

Cold spray is an emerging spray coating technology during which process spray particles take place through intensive plastic deformation upon impact in a solid state at temperatures well below their melting points. Therefore, spray particles experience little oxidation or decomposition during this process.

What are the types of thermal spraying?

- HVOF (High Velocity Oxy-Fuel Spraying) HVOF is a process which makes use of a torch that allows the flame to spread whenever the nozzle is used. …

- Combustion Flame Spraying. …

- Plasma Spraying. …

- Vacuum Plasma Spraying. …

- Two-Wire Electric Arc Spraying.

What are the applications of spray coating techniques?

In addition to original equipment applications, thermal spray coatings are used to repair parts worn and damaged in service, and restore dimensions to machined parts. Thermal spray coatings are used to restore the dimensions of components that have been worn or corroded, such as printing rolls and undersized bearings.

Where is thermal spraying used?

Thermal spray coatings are extensively used in the manufacturing of gas turbines, diesel engines, bearings, journals, pumps, compressors and oil field equipment, as well as coating medical implants.

What is spray metal coating?

What Does Metal Spray Coating Mean? Thermal spraying is a group of coating processes in which finely divided metallic or nonmetallic materials are deposited in a molten or semi-molten state to form a coating. The coating material may be a powder, ceramic rod, wire or molten material.

What is warm spraying?

A novel coating process called ‘warm spraying’ has been developed, in which coatings are formed by the high-velocity impact of solid powder particles heated to appropriate temperatures below the melting point of the powder material.

How is thermal spray applied?

Thermal spray coating is an industrialized process that combines a heat source with a wire or powder coating material. The material is then melted into droplets and sprayed onto a surface at a high velocity.

What are the two main methods of metal spraying?

Both flame spraying and arc spraying techniques are used to add these protective coatings.

Which metal is used for metal spraying?

A zinc-aluminium alloy is sprayed on as corrosion protection. Molybdenum, bronze, nickel, NiCrBSi, chrome-nickel-iron alloys and Wolfram/ Tungstencarbide hard metal are used as wear protection in surface coating.

What are organic coatings?

An organic coating is a type of coating formed by carbon-based polymeric chains derived from natural (vegetable, animal) or synthetic matter. Solid, adhesive and cohesive organic coatings can be found in the form of paints, varnishes, lacquers.

What is MIG spray?

How thick can you spray weld?

The limitations of spray-arc welding are: It is only used for material 1/8 inch (3mm) thick and thicker (handheld) and. It is limited to flat and horizontal fillet weld positions. Good fit-up is always required as there is no open root capability.

How hot is spray welding?

The process operates at over 10,000C, which is hotter than the melting point for metals. The powder is injected into the flame, melted, and moved to the material being sprayed. The advantages of the plasma transferred arc welding process include that it is easy to apply.

Which gas is used in cold spray?

Cold spray uses an electrically heated high-pressure carrier gas, like nitrogen or helium, to accelerate metal powders through a supersonic de Laval nozzle above a critical velocity for particle adhesion.

What is the difference between cold and thermal spray?

The big difference is the particle size of the powder that can be sprayed. Cold spray can spray much finer particles, including nanocrystalline powders. Cold spray powders typically have a grain size of 1-50 µm whereas thermal spray powders vary from 10-100 µm depending on the specific thermal spray process.

What is cold spray made of?

Liquified petroleum gas including propane and butane is sometimes used. These all may also be used as a topical anesthetic, due to the numbing effect of cold, though there is risk of frostbite.

How many types of coating pans are there?

There are three types of conventional coating pans. Besides conventional coating pan, there are perforated coating pans.

What is ultrasonic coating?

Ultrasonic coating is a unique, environmentally-friendly, low velocity spray technology that creates micron thickness, very uniform protective and functional thin films with no clogging and very little overspray.

How does dip coating work?

Dip coating is a process by which substrate material is submerged in conformal coating, then taken out and allowed to drip dry. Once the excess coating has drained, the substrate material is further dried using one of a variety of techniques, often baking.