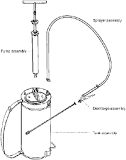

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig. 9.4).

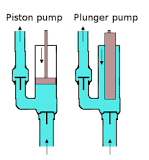

What’s better a diaphragm or a piston pump sprayer? Piston – A piston pump is the better option when spraying anything at a distance, such as trees and bushes, because of its higher pressure. They are normally a little less expensive and easier to repair. However, they aren’t as durable as a diaphragm pump.

What is a piston pump sprayer? Piston sprayers include a cylinder housing in which, when pumping, a piston moves up and down to create pressure. Most piston models can reach up to 90 psi. Higher psi delivers smaller droplet size and has a further reach. Use with low abrasive, low viscosity spray liquids such as herbicides and insecticides.

What is difference between diaphragm and piston? Diaphragm-sensed regulators use a flexible element to adjust to these changes and to ensure constant outlet pressure and flow relative to depth; piston-sensed regulators use a sliding metallic piston that moves to adapt to these variations.

Which is the best spray pump?

- Petrol Portable STIHL Power Sprayer SG 230.

- IBell Power Sprayer.

- Fortune Power Sprayer.

- Kisankraft Power Sprayer.

- Neptune Knapsack Farming Power Sprayer.

- E-AgroCare Knapsack Sprayer.

- Fujiaka Power Sprayer.

- BKR Honda Four Stroke Power Sprayer.

Is piston or diaphragm backpack sprayer?

How does a compression sprayer work? – Related Questions

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

How do you pump a backpack sprayer?

How does a pump sprayer work?

How does a compression sprayer work?

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig. 9.4).

How does a piston regulator work?

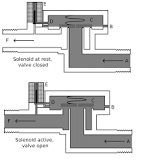

When the regulator is pressurized by opening in the tank, the piston moves and allows air to past the high pressure seat. When the pressure inside the regulator reaches IP, then it closes, and air stops flowing. When you take a breath, it moves and lets air through.

What is a piston flush valve?

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

What is the desirable quality of sprayer?

Desirable quality of a sprayer It should deliver the liquid at sufficient pressure so that the spray solution reaches all the foliage and spreads uniformly over the plant body. It should be light in weight yet sufficiently strong, easily workable and repairable.

Which is best spray pump for agriculture?

- Neptune PBS-13 PLUS.

- Neptune Rocker. The Neptune Rocker model is known for high performance and high durability. …

- Neptune Foot. …

- Neptune NF-8.0 Hand. …

- Neptune HTP Gold Plus. …

- Neptune HTP Gold. …

- Neptune HTP Silver. …

- Neptune Hariyali-08 Manual.

How does a backpack pump sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How do you put together a solo backpack sprayer?

What are the disadvantages of a diaphragm pump?

- They have little pulsation which may lead to the device damage.

- These pumps are persuaded not to push very accurately at their base section.

- Many of the diaphragm pumps typically need 20 cubic feet for every minute & nearly 100 PSI of air consumption to function efficiently.

What does a piston pump do?

A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used to move liquids or compress gases. They can operate over a wide range of pressures.

What are the advantages of a diaphragm pump?

- HANDLES A WIDE VARIETY OF FLUIDS WITH HIGH SOLIDS CONTENT: …

- SELF PRIMING. …

- ABILITY TO RUN DRY. …

- EXPLOSION PROOF. …

- PUMPING EFFICIENCY REMAINS CONSTANT. …

- VARIABLE FLOW RATE AND DISCHARGE PRESSURE. …

- CAN NOT OVERHEAT. …

- NO MECHANICAL SEALS, COUPLINGS, OR MOTORS.

How do you calculate gpm for a sprayer?

The formula GPM = (GPA x MPH x W)/5,940 has several constants: square feet per acre, feet in a mile, and time measured in minutes. MPH x W provides the square feet of coverage in an hour. You’re looking for gallons per minute.

How do you adjust the pressure in a solo backpack sprayer?

To adjust, push down on the knob and rotate to align the desired number with the alignment pin. If a spray pressure exceeding 60 psi (4 bar) is required, first release the excess pressure and then replace the adjustment piece with the optional plug (#4200215).

Why is my Fimco sprayer not building pressure?

If you’re experiencing little to no pressure or the pump is not priming and you’ve checked your filter screen and it’s clean, you may need to clean the check valve. Remove the head of the pump, which is held on by about 6-7 screws. for building up pressure and pumping water/solution through the lines.

How much pressure should a pump sprayer have?

Most hand pump sprayers are limited to about 40 psi.

Why is my sprayer not building pressure?

If you are experiencing low pressure output from your sprayer and have ruled out any other parts as the cause, the impeller coupling may have lost its seal, or the impeller itself may be damaged, clogged or broken. In some cases, the pump may be disassembled and cleaned to fix the problem.

Why is my pump sprayer not spraying?

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What is compressed air sprayers?

Compressed air sprayers, or pump up handheld sprayers, are common fixtures on many farms and ranches. They provide a fast and effective method of spot treatments for weed, insect, disease and fertilizer applications.

What is hydraulic sprayer?

Definition of hydraulic sprayer : a machine for the large-scale application of insecticides or fungicides to crops in the form of a spray — compare mist blower.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.