Is diaphragm or piston sprayer better? Piston pumps work best with lighter chemicals, such as herbicides and insecticides. Diaphragm – Diaphragm pumps don’t deliver as much pressure as piston, making them ideal for use in close application scenarios such as weed killing. But the diaphragm pump is more durable to chemical damage.

What is difference between diaphragm and piston? Diaphragm-sensed regulators use a flexible element to adjust to these changes and to ensure constant outlet pressure and flow relative to depth; piston-sensed regulators use a sliding metallic piston that moves to adapt to these variations.

What is a diaphragm sprayer pump? Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of a housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

How many gallons per acre is a backpack sprayer? The water in the sprayer is then sprayed into a measuring container for 27 seconds. The result is 20 ounces captured, making the sprayer output 20 gallons per acre.

How does a diaphragm sprayer work? Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

How do you pump a backpack sprayer? – Related Questions

How does a diaphragm airless paint sprayer work?

Diaphragm pumps In a diaphragm pump, a rod powered by a motor operates diaphragms that expand and contract, taking in fluid through the inlet valve and expelling it out of the gun.

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

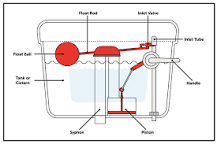

What is a toilet diaphragm?

Diaphragm assemblies regulate pressure inside the valve using a flexible rubber disc (diaphragm) that seals the valve seat after each flush. Diaphragms that becomes worn or warped may either stick in place to prevent flushing or fail to seal so that the toilet keeps running.

How does a backpack pump sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How does a pump sprayer work?

How long does it take to spray 1000 square feet?

143′ length x 7′ width = 1,000 square feet covered by your technicians every 30 seconds. However, keep in mind that all turf gets sprayed twice. That means you are achieving an effective coverage of 1,000 square feet every 60 seconds.

How many gallons does it take to spray 1000 square feet?

The product label recommends that 4 fluid ounces of herbicide be mixed in 2 to 4 gallons of water to cover 1000 square feet (sq ft).

How much area can a 4 gallon backpack sprayer cover?

Your sprayer is now calibrated to spray 64 gallons of water per acre (64 GPA) You have a (4) gallon backpack sprayer. Divide (4) gallons by (64) GPA 4/64=. 0625 Which means your sprayer can spray . 0625 or 2723 square feet with one tank full.

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

Do diaphragm pumps need lubrication?

And when your equipment performs with the versatility and durability that your application demands, you can keep things running smoothly. Air operated diaphragm pumps are rugged, lube-free, non-stall/freeze pumps that provide the high quality, trouble-free, continuous output—even under the toughest conditions.

Can a diaphragm pump pull a vacuum?

Modern multi-stage diaphragm pumps can provide vacuum levels throughout the entire rough vacuum range (atmosphere to below 1 mbar/torr) providing vacuum levels suitable for many tasks. Standard models can perform degassing of liquids, and even be used as backing pumps for wide range turbomolecular pumps.

What PSI should latex paint be?

For spraying latex paint, there are two pressures to keep in mind, depending on what you are painting: A 26 – 29 PSI is suggested for a base coat on the surface being painted; A clear coat is better served by a lower 2 – 3 PSI for better atomization (remember that from earlier?) and flow.

Can you spray oil based paint with an airless sprayer?

Airless pain sprayers work with oil-based paint or stain. HVLP paint sprayers work with oil-based paint, but thicker paints such as water-based latex can clog the sprayer.

What causes tails when spraying paint?

Tails in airless spraying is a well-known problem. They are caused by incomplete atomization of the liquid throughout the spray pattern resulting in a solid stream when paint that is too high in viscosity is sprayed. This generally occurs at the outside edges of the of the spray pattern fan.

What are the disadvantages of a diaphragm pump?

| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

What are the advantages of a diaphragm pump?

- HANDLES A WIDE VARIETY OF FLUIDS WITH HIGH SOLIDS CONTENT: …

- SELF PRIMING. …

- ABILITY TO RUN DRY. …

- EXPLOSION PROOF. …

- PUMPING EFFICIENCY REMAINS CONSTANT. …

- VARIABLE FLOW RATE AND DISCHARGE PRESSURE. …

- CAN NOT OVERHEAT. …

- NO MECHANICAL SEALS, COUPLINGS, OR MOTORS.

Do diaphragm pumps need to be primed?

Diaphragm Pumps Are Self-Priming Unlike some other pumping technologies, AODD pumps are self-priming and don’t require positive inlet pressure to prime (flooded or needing a dry suction lift).

What is linear pump?

Linear peristaltic pumps transport fluid through a flexible duct using traveling contraction waves. In a typical linear peristaltic pump, discrete translational elements rhythmically compress a straight section of flexible tube, moving fluid volumes.

How does a linear air compressor work?

Linear compressors work similarly to a solenoid: by using a spring-loaded piston with an electromagnet connected to AC through a diode. The spring-loaded piston is the only moving part, and it is placed in the center of the electromagnet.

Why do toilet fill valves fail?

How do you replace a diaphragm?

What are toilet syphons?

A toilet syphon is a one-way valve, or ‘flap valve’ that’s used to help make flushing easier by boosting the flush, using the natural force of syphoning. This is because the toilet syphon works like a one-way diaphragm pushing water up and down a tube.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.