What is the difference between a piston and diaphragm sprayer?

What is a diaphragm spray pump? Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of a housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

Why is my solo sprayer leaking? The most common reason sprayers leak is a worn or damaged component, whether that be a valve or an O-ring. To fix a leaking sprayer, you need to locate the source of the leak.

How do you pressurize a backpack sprayer?

How far can a backpack sprayer spray? How far can a backpack sprayer spray? This depends on the pack, but most can handle between 10 and 30 feet, with an average of 20 feet.

How do you fix a solo backpack sprayer? – Related Questions

How does a diaphragm sprayer work?

Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

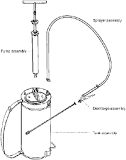

How does a backpack pump sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How do you release pressure on a solo backpack sprayer?

If the spray pressure must be changed, excess pressure in the pressure cylinder must be released back into the tank through the spray tube. To adjust, push down on the knob and rotate to align the desired number with the alignment pin.

Why is my pump sprayer not working?

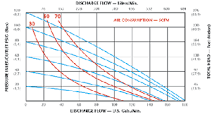

How much pressure should a pump sprayer have?

Most hand pump sprayers are limited to about 40 psi.

How do you calibrate a pump sprayer?

- Mark off a plot 18.5 feet by 18.5 feet.

- Fill the sprayer to normal capacity with water.

- Pump the sprayer to the pressure normally used to apply herbicides.

- Spray water over the plot area while maintaining normal and constant operating pressure.

- Record the time in seconds it takes to spray the plot area.

How do you pressurize a sprayer?

How many square feet will a 4 gallon sprayer cover?

Divide (4) gallons by (64) GPA 4/64=. 0625 Which means your sprayer can spray . 0625 or 2723 square feet with one tank full.

How long does it take to spray 1000 square feet?

143′ length x 7′ width = 1,000 square feet covered by your technicians every 30 seconds. However, keep in mind that all turf gets sprayed twice. That means you are achieving an effective coverage of 1,000 square feet every 60 seconds.

How many square feet will a backpack sprayer cover?

A backpack sprayer can typically cover between 1000 and 10,000 square feet. The total area it can cover depends on the application rate of the product being sprayed as well as the volume of the sprayer tank.

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

Do diaphragm pumps need lubrication?

They do not leak, offer little friction, and can be constructed for low pressure sensitivity. With the right material consideration, diaphragms can seal over a wide range of pressures and temperatures without needing lubrication or maintenance.

Do diaphragm pumps need to be primed?

Diaphragm Pumps Are Self-Priming Unlike some other pumping technologies, AODD pumps are self-priming and don’t require positive inlet pressure to prime (flooded or needing a dry suction lift).

What are the disadvantages of a diaphragm pump?

| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

What are the advantages of a diaphragm pump?

- HANDLES A WIDE VARIETY OF FLUIDS WITH HIGH SOLIDS CONTENT: …

- SELF PRIMING. …

- ABILITY TO RUN DRY. …

- EXPLOSION PROOF. …

- PUMPING EFFICIENCY REMAINS CONSTANT. …

- VARIABLE FLOW RATE AND DISCHARGE PRESSURE. …

- CAN NOT OVERHEAT. …

- NO MECHANICAL SEALS, COUPLINGS, OR MOTORS.

Can you flow through a diaphragm pump?

WHAT KIND OF FLUID DOES A DIAPHRAGM PUMP TRANSFER? Diaphragm pumps will move nearly any kind of fluid. Some common examples of fluids pumped using a diaphragm pump are water, oil and acid. Diaphragm pumps are capable of pumping high viscosity fluids from adhesives and gear oils to hand lotions, surfactants and resins.

How does a linear pump work?

The activated electro-magnet attracts the piston against the return spring, while air is taken into the cylinder through the opened inlet valve. When the electro-magnet is deactivated, the return spring pushes the piston back, and the compressed air is brought out of the cylinder through the now open outlet valve.

What is linear pump?

Linear peristaltic pumps transport fluid through a flexible duct using traveling contraction waves. In a typical linear peristaltic pump, discrete translational elements rhythmically compress a straight section of flexible tube, moving fluid volumes.

How does a linear air compressor work?

Linear compressors work similarly to a solenoid: by using a spring-loaded piston with an electromagnet connected to AC through a diode. The spring-loaded piston is the only moving part, and it is placed in the center of the electromagnet.

How much does a full backpack sprayer weigh?

Backpack sprayer’s filled with spray solution weigh 30 to 40 pounds. A comfortable and convenient carrying system is important to ensure operator comfort, reducing fatigue which enhances application practices.

How does a compression sprayer work?

A hand-compression sprayer basically consists of a tank for holding a liquid insecticide formulation, which can be pressurized by means of a hand pump attached to it. The compressed air forces the liquid from the tank via a hose with a cut-off valve, a lance and a nozzle (Fig. 9.4).

What are sprayer pumps?

Sprayer pumps are designed to push or pull fluid tank contents out to a spray nozzle(s) at specific gallons per minute (GPM) flow rates and pressure delivery.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.