- Wear appropriate safety equipment, such as goggles and gloves. …

- Make sure you have the right countersink angle. …

- Choose the right-sized countersink drill bit. …

- Insert the countersink bit into the drill press’ chuck and tighten firmly. …

- Set The Drill To the Correct Depth.

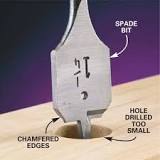

Can you countersink with a spade bit? Drilling. The first step when drilling a countersunk hole with a spade bit was to start with the countersink itself. This will allow both the larger spade bit (countersink) and the smaller (pilot hole) to grip the material and prevent “wobbling”.

What drill bit do you use to countersink?

What is a spade bit used for? Spade bits are for wood, plywood, and some plastics, and cut quickly with surprising precision. Use them only at high speeds, to prevent the bit from catching in the workpiece and the drill from trying to wrench itself from your grasp.

What are the different types of countersink? Countersink cutters are manufactured with six common angles, which are 60°, 82°, 90°, 100°, 110°, or 120°, with the two most common of those being 82° and 90°.

How do you countersink without a countersink bit? Improvised countersink. It’s not as clean as using a countersink bit, but it will work in a pinch. Another improvised way to countersink a screw is to drill your pilot hole with your regular drill bit and then use a Phillips head bit to hollow out a countersink divot to a depth where the screw head can lie flat.

How do you countersink metal screws? – Related Questions

Why are countersink bits tapered?

Given our experience and testing, we recommend countersinks with tapered bits because they cut faster and result in stronger screw connections. When a tapered-bit countersink is adjusted for shorter screws shows, a small gap around the drill bit opens. That opening collects debris.

What are the 5 types of drill bits?

- Twist bit. A twist bit (sometimes called a fluted bit) is far and away the most common type of drill bit, probably because it’s the one with the greatest number of uses. …

- Spade bit. …

- Hole saw. …

- Step bit. …

- High-carbon steel. …

- High-speed steel. …

- Carbide or carbide-tipped. …

- Coatings.

What tool is used to countersink screws?

For traditional tapered wood screws, a countersink with a tapered drill is logically the best to use. Straight wood screws, such as those ubiquitous black screws from the home center, work optimally with straight drill bits.

What size countersink bit for wood screws?

This wood countersink is for boring holes in wood to allow to countersink the screw head and to insert a plug if desired. The bit is 11/64″, and the countersink is for a #8 screw size. It allows for a 3/8″ plug. Tapered drill with widened flute drills fast clean pilot holes.

What is the difference between a drill bit and a spade bit?

The spade bit is the only drill bit that can drill multiple holes in a short time. The most affordable among all other drill bits is the spade bit. The cheapest drill bit among wood drill bits is a spade bit. Spade bits are a popular choice for drilling large diameter holes (1/2″ or more).

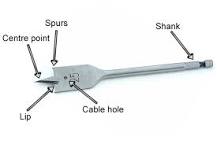

Why do spade bits have a hole?

The hole on a spade bit is used to pull electrical cables back through boreholes once they have been drilled. At a push, they can also be used to hang the spade bit on a wall-mounted rack.

Is a spade bit harsh?

They exert palate pressure (center spade) but also exert bar, chin and poll pressure from the action of the curb strap like a normal curb bit. They are not commonly used and can be extremely harsh.

What is a 90 degree countersink used for?

Used for cleaning holes, enlarging holes or countersinking holes. For use in a wide range of materials such as aluminum, metal, plastic, steel, wood and brass. They provide a smooth finish on a variety of materials.

What are 60 degree countersinks used for?

60-degree countersinks cut conical holes featuring 60-degree angles at their front tip into workpieces, allowing countersunk bolts, screws, or rivets with 60-degree angles to be fastened in them.

Why is it called countersink?

They are called “countersunk screws” because they “sink” into objects and surfaces. They feature a flat head that tapers along the shaft. Therefore, when you drive a countersunk screw into an object or surface, the head will sink so that it’s flush with the respective material.

Can you countersink with a regular drill bit?

If I have a regular 3/8″ drill bit I can slightly (and carefully) drill a countersink divot. But often I just use the spinning Phillips head driver bit and swing the drill in a circular motion around the hole at an angle a few times to create a countersink area before I zip the screw in.

What is a self countersinking screw?

Are there self countersinking screws?

R4 Self-Countersinking Flat-Head Multi-Purpose Screw (50 per Pack) 103141 – The Home Depot.

How do you control countersink depth?

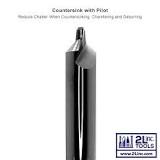

What is the purpose of countersink with pilot?

The Countersinks integrated pilot drill reduces chattering by allowing the pilot to closely fit into a pre-drilled hole. These Countersinks can be used for countersinking as well as chamfering and deburring. Each size may be used on a wide range of hole diameters.

How do you countersink a hole?

What is the strongest drill bit?

Carbide (Carb) is the hardest and most brittle of the drill bit materials. It’s used mostly for production drilling where a high-quality tool holder and equipment is used. It should not be used in hand drills or even drill presses. These drill bits are designed for the most demanding and hardest materials.

What are the Gold drill bits for?

Titanium Drill Bits – Best for Metals They’re easily recognisable as they have a gold-coloured coating. The titanium makes the bit much harder and is slightly self-lubricating, which makes it perfect for drilling hard metals.

What is the most common drill bit?

A twist bit is the most common type of drill bit for home use. It works for general-purpose drilling in wood, plastic and light metal.

How do you countersink on wood?

Clamp your wood down to secure it, then put a dot where you want to make your hole. Drill your pilot hole so it’s the same depth as the screw length. Next, put a fluted countersink cutter in your drill that’s the same size as your screw. Slowly drill into the pilot hole with the cutter to make your countersink.

Should I countersink deck screws?

Deck screws should be slightly countersunk below the decking surface. The finish screws set to approximately 1/8″ (3mm) below the decking’s surface. Providing a clean finish without any screw head protruding after the decking dries. The biggest concern is snagging your socks on a screw as you stroll across the deck.

What is the most common countersink angle?

The most common countersink angle for screws is 82 degrees based on the Unified Thread Standard.

What size is a #10 countersink?

#10 Countersink 3/16 in.

What size is a #8 countersink?

The Milwaukee #8 Countersink features a 11/64 in. Drill Bit. The pre-drill and countersink bits are designed for use in Milwaukee Drill Drivers.

What’s the difference between a Forstner bit and a spade bit?

Spade bits are the smallest of the three hole cutting tools; they generally come in a range of ⅜ an inch and 1 ½ inches. Forstners are a bit larger; their range is from ¼ an inch to 2 ¼ inches. The cutting diameter of a carbide burr ranges from 3/32” to 1” and only up to about 1” in cutting depth.

Is a spade bit harsh?

They exert palate pressure (center spade) but also exert bar, chin and poll pressure from the action of the curb strap like a normal curb bit. They are not commonly used and can be extremely harsh.

Are Forstner bits better than spade bits?

Simply put, spade bits are fast and dirty, while Forstner bits are slow and precise. In fact, if you’re not careful when using a spade bit, the speed can cause tear out and splintering on the opposite side of the workpiece.

How do you make a hole bigger with a spade bit?

To get the hole larger, file the sides of the larger spade bit at a 60-degree angle. Leave the edges of the filed areas sharp so they cut as you push the bit in with your drill. Hold the drill firmly as you carefully expand the hole.