In a convergent nozzle, there is an increase in velocity and a decrease in pressure, but we know that pressure is inversely proportional to area.

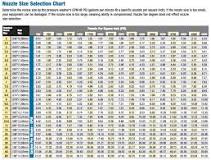

How do I choose a sprayer nozzle? The best method for choosing the correct nozzle tip size is to determine the gallons per minute (GPM) of nozzle output required and then select a nozzle tip size that, when operated within the recommended pressure range, will provide this flow rate.

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

What is a Boomless sprayer nozzle? Boomless nozzles are used for spraying areas not easily accessed with a boom. Choose from single brass, stainless steel, nylon nozzles or the double-sided BoomJet suited for large capacity 12 volt or medium pressure diaphragm pumps. Boomless nozzles can spray widths from 3 to 19 metres.

What are the different types of nozzles used in the sprayers? Nozzle Description. Nozzle types commonly used in low-pressure agricultural sprayers include flat-fan, flood, raindrop, hollow-cone, full-cone, and others. Special features, or subtypes such as “extended range,” are available for some nozzle types.

How do I choose a nozzle size? The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

Do nozzles increase pressure? – Related Questions

What are the 2 types of nozzles?

The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

Which is the mostly used nozzle?

Round Nozzle It is the most used nozzle by the bakers around the world.

What are different types of sprayers?

- Knapsack Sprayer.

- Portable Power Sprayer.

- Knapsack Power Sprayer.

- Mist Dust Sprayer.

- HTP Sprayers.

- Orchard Sprayers.

What is a broadcast nozzle?

Broadcast spray nozzles are typically used for broadcast applications on a boom type sprayer. The nozzles are noted for their tapered, flat spray patterns that overlap one another along the boom.

How do you attach a Boomless spray nozzle?

What’s a boom sprayer?

A boom sprayer is the most common type of apparatus for applying herbicides in broadscale farming. A sprayer has many components, the most important being the nozzles, which split the herbicide into many small droplets that are projected through the air to the target.

What do the numbers on spray nozzles mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

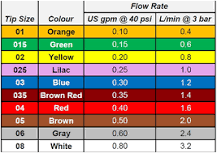

What do teejet nozzle numbers mean?

These numbers refer to the flow rate in US gallons at the rated pressure of 40 PSI (approx. 3 BAR). For example, an 02 Nozzle is rated at 0.2 US gallons per hour at a pressure of 40 PSI.

What is a cone nozzle used for?

Solid cone nozzles are suitable for application of residual herbicides and systemic insecticides using a knapsack or boom mounted or for spot applications of herbicides. They produce a full cone spray pattern with coarse droplets at a pressure of 1 – 10 bar.

Does a bigger nozzle print faster?

The larger nozzle diameter will offer faster print speeds and allow more efficient toolpaths. The standard 0.8mm walls will now only require a single pass to lay down. I think this is a case where the larger 2.85mm filament offers some much-needed leeway.

Are DiamondBack nozzles worth it?

The DiamondBack Nozzle delivers precision prints, prints any filament, and offers a much longer nozzle life. In addition, the DiamondBack is easier to clean, reduces tip clogging, improves layer adhesion, lowers operating temperature, and delivers unmatched wear resistance.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

How does nozzle size affect velocity?

The larger nozzle diameter gives more mass of fluid to be carried. It is also related to the momentum energy generated that when the fluid velocity s constant with increasing fluid mass so the momentum gets larger then the jt plunges deeper.

What is a drop nozzle?

Cone Tips | Nozzle Assemblies | Drop Nozzles. Like band spraying, Drop Nozzles can be used to apply pesticide directly in a band either over the row, at the base of the plant from between the row, or both. Unlike band spraying, thought, these drops are usually used for post emergent spraying.

What is solid cone nozzle?

Solid cone spray nozzles, or full cone nozzles as they’re otherwise known, produce a solid cone-shaped spray pattern with a round or square impact area. They usually produce medium to large sized droplets for uniform distribution at a range of pressures and flow rates.

How many types of nozzles are there?

There are 5 basic spray pattern types: flat fan, solid stream, full cone, hollow cone and mist/fog. Various nozzle designs are deployed to create these patterns and details on each can be found in the sections below.

How do you use a star nozzle?

Are all piping tips numbers the same?

Decorating tips are assigned different numbers based on the shape and size of their openings.

Does a smaller nozzle increase pressure?

Choosing the Right Nozzle for Your Machine The orifice size of the nozzle determines the operating pressure of your machine. As a rule of thumb, the smaller the orifice, the greater the restriction of water flowing through the machine. This causes the pressure to increase.

Is a turbo nozzle worth it?

Turbo nozzles have been one of the most important accessories developed. These efficient tools provide the power of a zero-degree pattern. The circular motion also adds extra agitation to cleaning tough jobs like caked-on mud. They are designed to provide a 200% cleaning efficiency over a 25-degree flat fan nozzle.

What pressure should a sprayer be?

Running from 40-80 PSI usually. As crw said, the controller will try to match the pump to your ground speed by changing the speed of the pump. That will of course affect the pressure at the nozzles. Lower pressures should mean courser droplets, high pressure = finer droplets.

What are the 4 main sprayer components?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

What is the desirable quality of sprayer?

Desirable quality of a sprayer It should deliver the liquid at sufficient pressure so that the spray solution reaches all the foliage and spreads uniformly over the plant body. It should be light in weight yet sufficiently strong, easily workable and repairable.

What is difference between duster and sprayer?

Sprayers are used to manage pests by using natural materials such as contaminations and small creatures in sprayers. A duster insecticide is a helpful tool for getting pesticides deep into cracks, crannies, and other similar spaces to kill crawling and flying insects, such as scorpions, bees, and other pests.

How will you select a nozzle for a particular type of job?

- Select the application rate in gallons per acre (gpa). …

- Select a practical and safe ground speed in miles per hour (mph).

- Determine the spray width per nozzle (W).

- Determine the flow rate (gpm) required from each nozzle by using the following equation:

How do you size a pressure washer nozzle?

There are a variety of sizes but the most commonly used are between 3.0 to 6.5, sized in . 5 increments. All nozzles are stamped with a 5 digit number which identifies both the fan degree and nozzle size. For example, a nozzle with the number 40055 has a 40 degree fan pattern and is 5.5 in size.

Which type of nozzle should be used for the spraying of pesticides?

Fan Nozzles The most common type of nozzle used in agriculture is the fan nozzle. A fan nozzle is widely used for spraying pesticides — both banding (over and between rows) and broadcast applications. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2).

What are the different types of fire nozzles?

- Smooth or solid bore.

- Fixed orifice or single gallonage (sometimes called variable pressure/variable flow)

- Selectable or adjustable gallonage.

- Automatic or constant pressure.

- Multi-purpose nozzle (combination smooth bore and fog)