(+44) 01452 523352. Hydraulic motors and pumps, like all hydraulic equipment, need adequate lubrication to function properly. A lack of lubrication causes moving parts to grind against each other, causing wear and tear and also generating heat – both things which cause severe yet preventable damage to the equipment.

How do hypro pump work? The pump operates by receiving a fluid through the inlet port where it is captured and transported by the rollers, and then expelled through the outlet port. Construction features include housings and rollers, which are made in a variety of materials in order to be resistant to a wide range of chemicals.

How do you prime a hypro pump? Spin the valve open a couple turns, wait until liquid flows from the drain valve, then screw the valve tight. takes all of 5 seconds to purge the air out. The plug on the housing is your vent line and should be hooked up during normal operation to help with priming.

Are hypro roller pumps self priming? HYPRO ® 6 Roller Water Pump This device is a self-priming pump with a maximum flow of 22 GPM at 1200 RPM. This pump will work well for almost all of your agricultural needs.

How do I winterize my hypro pump? Plug the inlet and outlet ports of the pump if you are going to store the pump inside or off the sprayer system. storage will help clean the surfaces from any residue that has accumulated. Then flush the pump with a RV antifreeze (propylene glycol) mixed at 50/50 with water. This will protect the pump from freezing.

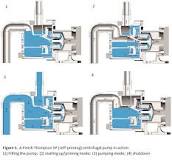

What is the difference between roller pump and centrifugal pump? Centrifugal pumps are considered to be less destructive to blood elements (1) when compared to roller pumps. However, their large prime volumes render them unsuitable as arterial pumps in heart lung machine (HLM) circuitry for children.

Can you run a hydraulic pump without oil? – Related Questions

How does roller pump work?

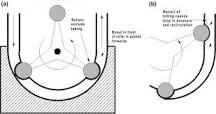

A peristaltic pump, also commonly known as a roller pump, is a type of positive displacement pump used for pumping a variety of fluids. The fluid is contained in a flexible tube fitted inside a circular pump casing. Most peristaltic pumps work through rotary motion, though linear peristaltic pumps have also been made.

What causes a pump to lose its prime?

Your well pump begins cycling air instead of water. Well pumps can lose their prime for several reasons. If your well water level is too low, you may have pulled too much water from the system. There isn’t enough water in the well to be drawn up by the pump.

Do hydraulic pumps need primed?

Not all hydraulic pumps require priming. Some rely on air pressure and gravity to ensure that the suction line and pump remain air-free.

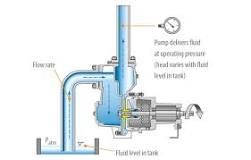

How does a self-priming pump work?

How Do Self-Priming Pumps Work? To avoid the mixing of air and water, self-priming pumps create a partial vacuum to discharge water while also evacuating any air. It does this by combining the air and water during the priming process, forcing the air to rise and the water to sink or go down.

Does a roller pump need primed?

Roller pumps have a pressure range up to 300 psi and flow rates up to 74 gpm. These products are self-priming and easily adapt to PTO or gas engine drives. These pumps require no check valves while providing positive displacement characteristics.

How do you clean a roller pump?

Cleaning your roller pump after every use is easy and will prevent downtime. Flush the pump with a neutralizing solution depending on the liquid just pumped. Follow this with a clean rinse using fresh water. Don’t forget to wipe down the pump after each use to prevent deposits from forming and damaging it.

What is a PTO roller pump?

How much antifreeze Do I need to winterize my sprayer?

Put approximately 40 gallons of RV antifreeze in the product tank and about 5 gallons into the rinse tank. Put 3 gallons in the chemical eductor if it is equipped with one. RV antifreeze is not intended to be diluted with water, so purge as much water as possible from the system before adding the antifreeze.

What to use to winterize a sprayer?

Pour antifreeze into the spray tank. It is also important to winterize the rinse tank if your sprayer is equipped with one. Start by pouring antifreeze solution into the rinse tank. Then, turn on the system to pump antifreeze into the larger spray tank. This will protect the rinse lines from freezing.

How do you drain a sprayer pump?

Blow out the Plumbing Lines – Using compressed air, blow out the hose lines to remove all water from the system. Flush with Anti-freeze – Pour a small amount of anti-freeze into the tank and run the pump until the colored liquid starts coming through the spray ends.

Who invented roller pump?

Mechanical circulatory support got its start in 1934 when Dr Michael DeBakey developed the concept of a roller pump to facilitate blood transfusions. Twenty years later Dr John Gibbon, along with a team of five engineers from IBM, created the first cardiopulmonary bypass machine.

What is the reason of selecting roller pump in bypass machines over the more effective centrifugal pumps?

Cardiopulmonary Bypass and Management The two pumps used most commonly for CPB are roller pumps and centrifugal pumps. Roller pumps have the advantages of simplicity, low cost, ease and reliability of flow calculation, and the ability to pump against increased resistance without reducing flow.

How does centrifugal blood pump work?

Centrifugal pumps act through a spinning rotor to generate blood flow. This technique avoids high pressures in the case of distal circuit occlusion, but it may induce shear stress and turbulence to blood cells that may lead to hemolysis and thromboembolic complications.

How does a squeeze pump work?

The pump operates using positive displacement to move a variety of fluids. The fluid moves within a flexible tube fitted inside a circular pump casing. A rotor with a number of “rollers” turns, the part of the tube under compression is pinched closed (or “occludes”), forcing the fluid to be pumped through the tube.

What is pump displacement?

A Positive Displacement pump (PD pump) is a mechanical device which displaces a known quantity of liquid for every revolution or cycle that the pump completes. The flow rate through a positive displacement pump is directly proportional to its speed and number of cycles over a given time.

What is a rotary lobe pump?

Rotary lobe pumps are positive-displacement type pumps that use two or more lobes rotating around parallel shafts in the pump’s body to move liquids. They are widely used in the hygienic processing industries, including food & beverage processing and biopharmaceutical manufacturing.

How much water is needed to prime a pump?

Ideally, you want about a gallon or two for priming your water pump. This can depend on how deep or shallow the well is and if there is any existing water pressure in the lines. Keep in mind if you are planning to drink from this well, you will need a gallon or two of clean drinking water for the priming process.

How do I keep my pump primed?

- Make sure the power is turned off. Never leave a pump plugged in while you’re working on it. …

- Gain access to the pump system. …

- Check for damage. …

- Test a hose. …

- Open the relief valves. …

- Attach the hose. …

- Turn on the water and wait for it to enter the tank. …

- Turn the power on.

Why does my water pump keep losing pressure?

What happens if pump is not primed?

If you don’t prime your pump, you risk mechanical seal failure, and further damage to other necessary pump components. Without proper priming, your water pump’s motor will still run, but you’ll notice low water pressure, or no fluid delivery at all.

How do I know if my hydraulic pump is bad?

- Interior Leaks. Liquids should remain in the tubes that were designed for them. …

- Exterior Leaks. Have you discovered liquid on the outside of your pump? …

- Heat Degradation. …

- Water Contamination. …

- Failing Seals. …

- Slow Performance.

Can self priming pump run dry?

Even a ‘self-priming’ centrifugal pump will not operate when dry. With appropriate bearings and seals, a centrifugal pump can tolerate dry running for a limited time but this is not recommended for extended periods.

What is difference between centrifugal pump and self priming pump?

In normal conditions, common centrifugal pumps are unable to evacuate the air from an inlet line leading to a fluid level whose geodetic altitude is below that of the pump. Self-priming pumps have to be capable of evacuating air (see Venting) from the pump suction line without any external auxiliary devices.

Which pump does not need priming?

Normally, Centrifugal pumps need priming and Positive Displacement Pumps (Rotary Pumps, Reciprocating Pumps) does not require priming.

What is HyPro?

HyPro Incorporated is a value leader in the machining, manufacturing, and assembly of components and complex assemblies.