The type of PTO you choose definitely depends on the job you need to do. If you’re plowing, mowing, or shredding, there is a Power Take-Off shaft that is best for each task and helps guard your machinery against unnecessary pressure, hits, or tension.

What is a roller pump on a sprayer? Roller Pumps are reliable and durable pumps that perform spraying and fluid transfer applications. The pumps available are offered in a wide range of flow rates, allowing models to exist for both lower and higher pressure applications.

How do you hook up a PTO pump sprayer?

How do you size a roller pump? The flow required for agitation is a little easier as that is determined by tank size. For a 500-gallon tank you’re looking at 25gpm, 750-gallon tank will be 37 gpm, 1,000-gallon tank at 50 gpm and 1,500-gallon tank at 75 gpm. 3.) Choose the pump based on the manufacturer’s catalog performance charts.

How does a hydraulic PTO pump work? PTO transfers the power of the engine to a hydraulic pump. The hydraulic pump produces a hydraulic oil flow and pressure. The hydraulic oil flow is led to the piece of hydraulic equipment through the pressure line and back to the system’s hydraulic oil tank through the return line.

How long do roller pumps last?

| Availability | In Stock Online |

|---|---|

| Mix Rate | Ready to use. |

| Shelf Life | Hypro 6500XL-R Silver Series Roller Pump will last for 3 years in storage when kept in a dry, clean location. |

| Yield | Hypro 6500XL-R Silver Series Roller Pump can be used on one spray rig or power sprayer. |

| Use Sites | Outdoors |

Are all PTO the same? – Related Questions

What is the difference between roller pump and centrifugal pump?

Centrifugal pumps are considered to be less destructive to blood elements (1) when compared to roller pumps. However, their large prime volumes render them unsuitable as arterial pumps in heart lung machine (HLM) circuitry for children.

How do you prime a tractor sprayer?

How do you hitch a PTO?

How do you install a Fimco sprayer?

How big of pump do I need for my sprayer?

For boom spraying we would recommend the seven gallon per minute pump which will give you good pressure and flow for a small to medium sized boom.

Can you use a transfer pump for a sprayer?

Transfer pumps, in particular, are widely used for spray equipment and can help you tackle both the simplest and toughest of spraying jobs.

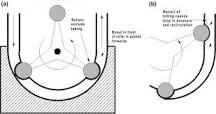

How does a roller pump work?

The pump operates by receiving a fluid through the inlet port where it is captured and transported by the rollers, and then expelled through the outlet port. Construction features include housings and rollers, which are made in a variety of materials in order to be resistant to a wide range of chemicals.

What causes PTO failure?

Slipping and overheating are common causes of these issues and are fixable by disassembling, inspecting, and replacing if necessary. Clutch will not stay engaged. Improper adjustment is the most common cause, remedied through adjusting engagement torque. PTO is hot.

How many types of PTO are there?

There are two major types of independent PTO; mechanical and hydraulic. A mechanical-independent PTO uses a separate on-off selector, in addition to the PTO control lever. Often the tractor must be stopped or off to change this selector position.

What does PTO stand for hydraulic pump?

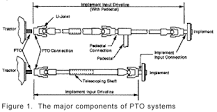

Power take-off (PTO) is a device that transfers an engine’s mechanical power to another piece of equipment. A PTO allows the hosting energy source to transmit power to additional equipment that does not have its own engine or motor.

How do I know if my roller pump is bad?

Rollers: Much like the rotor, undersized or swollen rotors in both length and diameter are not good. Measure the thickness and make sure it’s no smaller than 1.4995. Any smaller and it may be worn out and need to be replaced. Oh and make sure you replace rollers as a set, not just one at a time.

How do you maintain a roller pump?

Cleaning your roller pump after every use is easy and will prevent downtime. Flush the pump with a neutralizing solution depending on the liquid just pumped. Follow this with a clean rinse using fresh water. Don’t forget to wipe down the pump after each use to prevent deposits from forming and damaging it.

What is the reason of selecting roller pump in bypass machines over the more effective centrifugal pumps?

Cardiopulmonary Bypass and Management The two pumps used most commonly for CPB are roller pumps and centrifugal pumps. Roller pumps have the advantages of simplicity, low cost, ease and reliability of flow calculation, and the ability to pump against increased resistance without reducing flow.

Who invented roller pump?

Mechanical circulatory support got its start in 1934 when Dr Michael DeBakey developed the concept of a roller pump to facilitate blood transfusions. Twenty years later Dr John Gibbon, along with a team of five engineers from IBM, created the first cardiopulmonary bypass machine.

Is ECMO centrifugal pump?

The ECMO circuit is composed of a centrifugal pump; a membrane oxygenator; and cannulae for drainage and reinfusion of the patient’s blood, tubing, and connectors.

Why is my pump sprayer not working?

What are the 4 main components of a sprayer?

The major components of a sprayer are tank, pump, agitator, flow control, and nozzles.

How do I prime Petra pump?

Which way does a tractor PTO turn?

ISO 7000 – 1664, Power take-off (PTO), direction of rotation, clockwise.

What are the different types of PTO shafts?

- Transmission PTO shaft.

- Live PTO shaft (two-stage clutch PTO Shaft)

- Economy PTO shaft.

- Independent PTO shaft.

- Reverse PTO shaft.

Why is my Fimco sprayer not building pressure?

If you’re experiencing little to no pressure or the pump is not priming and you’ve checked your filter screen and it’s clean, you may need to clean the check valve. Remove the head of the pump, which is held on by about 6-7 screws. for building up pressure and pumping water/solution through the lines.

How do I increase the pressure on my Fimco sprayer?

When you are ready to spray, turn the boom valve to the “on” position. This will start solution spraying from the tips of the boom. The pressure will decrease slightly when the boom is spraying. Adjust the pressure by turning the “ON/OFF” valve lever on the bypass line valve.

How do you calibrate a Fimco sprayer?

What does a PTO pressure switch do?

When the Power Take Off (PTO) switch is turned ON, 12 volts is sent to the PTO solenoid to engage the PTO. This sends transmission pressure to the PTO to engage. When pressure is sensed, the PTO pressure switch sends a signal (usually ground signal), to the chassis controller indicating that the PTO is engaged.

How does a PTO work on a tractor?

The tractor’s stub shaft, often called the PTO, transfers power from the tractor to the PTO-driven machine or implement. Power transfer is accomplished by connecting a drive shaft from the machinery to the tractor’s PTO stub shaft. The PTO and drive shaft rotate at 540 rpm (9 times/sec.) or 1,000 rpm (16.6 times/sec.)

What does a 540 PTO mean?

The 540/540 Economy PTO allows operators to select the engine rpm needed for their power take-off (PTO) application. The economy position provides 540 rpm to the PTO at 1700 engine rpm.

How does a fire truck PTO work?

PTO (Power Take Off) generates power by changing engine rotation to “Hydraulic”. Hydraulic pressure is a mechanism that uses fluid called hydraulic fluid as an energy transmission medium. Hydraulic have the advantage of being able to move big thing with little power.